Carburizing and quenching heat treatment equipment for universal joint shaft sleeve blank and treatment process thereof

A blank carburizing and universal joint shaft technology is applied in the field of universal joint bushing blank carburizing and quenching heat treatment equipment and its processing technology. degree, the effect of protecting the bushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

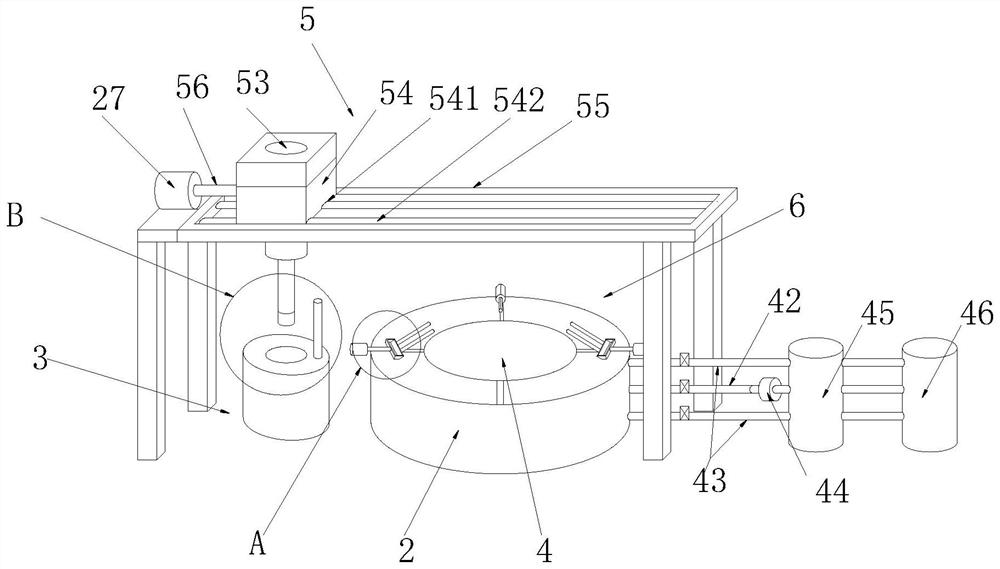

[0038] This embodiment is an embodiment of the carburizing and quenching heat treatment equipment and the treatment process for the blank of the universal joint bushing.

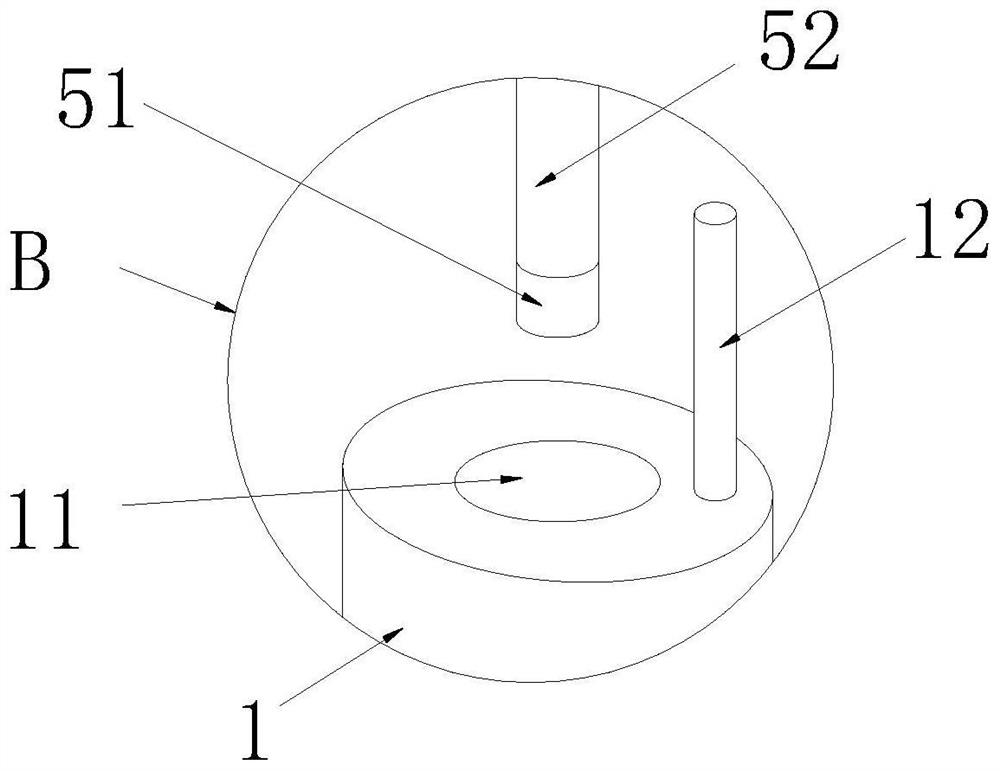

[0039] see Figure 1-7 , carburizing and quenching heat treatment equipment for universal joint bushing blanks and its treatment process, including carburizing furnace body 1, quenching pool 2, stabilizing mechanism 3 and quenching mechanism 4, stabilizing mechanism 3 is arranged inside the carburizing furnace body 1, quenching The mechanism 4 is arranged inside the quenching pool 2, and the quenching pool 2 is located on the right side of the carburizing furnace body 1;

[0040] Through the above technical solution, when it is necessary to carburize and quench the blank of the universal joint shaft sleeve, the staff will place each shaft sleeve on the stabilizing mechanism 3, and then place the stabilizing mechanism 3 on the carburizing furnace body 1 The inside of the shaft is waiting for carburizing heat...

Embodiment 2

[0067] This embodiment is an embodiment of the heat treatment process of the carburizing and quenching heat treatment equipment for the blank of the universal joint bushing.

[0068] The heat treatment process of the carburizing and quenching heat treatment equipment for the blank of the universal joint shaft sleeve includes the following steps, and is characterized in that:

[0069] S1: Place the limit position, separate the bushings that need to be carburized and quenched and place them inside the stabilization mechanism 3;

[0070] S2: carburizing heat treatment, place the sleeve carburizing bracket 32 inside the carburizing furnace body 1 through the lifting mechanism 5;

[0071] S3: Quenching, the shaft sleeve carburizing support 32 is transported to the interior of the quenching pool 2 through the lifting mechanism 5;

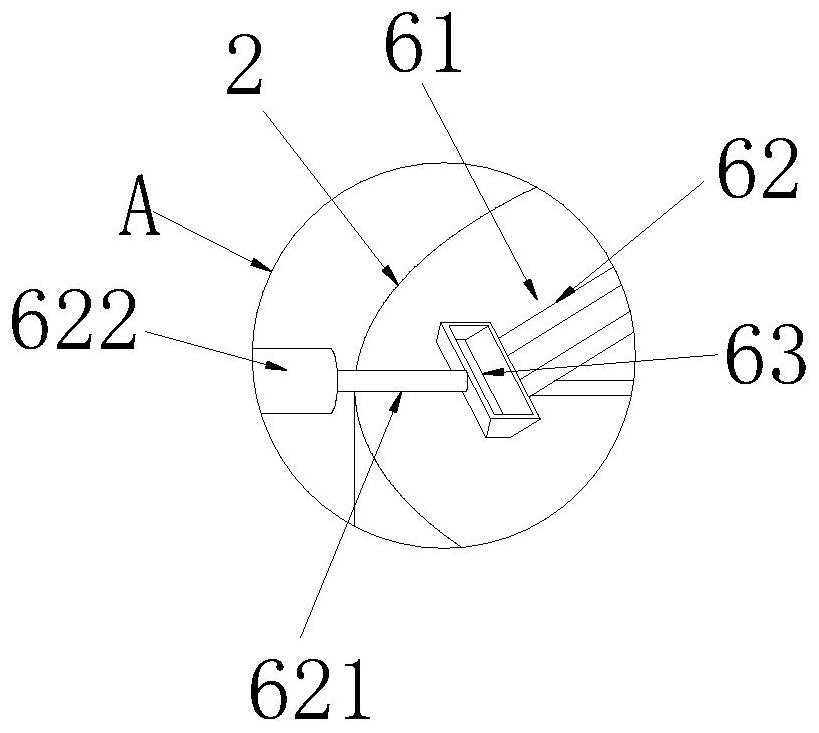

[0072] S4: Collecting, the pick-up rod 62 is driven by the pick-up mechanism 6 to collect the bushes hung on the carburizing support 32 of the bushes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com