A pulsed electric field treatment chamber

A pulsed electric field and processing chamber technology, which is used in non-electric variable control, food preservation, instruments, etc., can solve the problems of inability to adjust the temperature of the pulsed electric field processing chamber in real time, low modularity, and low cooling efficiency, and achieve real-time monitoring. , to solve the heating effect, to achieve the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments are only used to explain the present invention, and are not intended to limit the present invention.

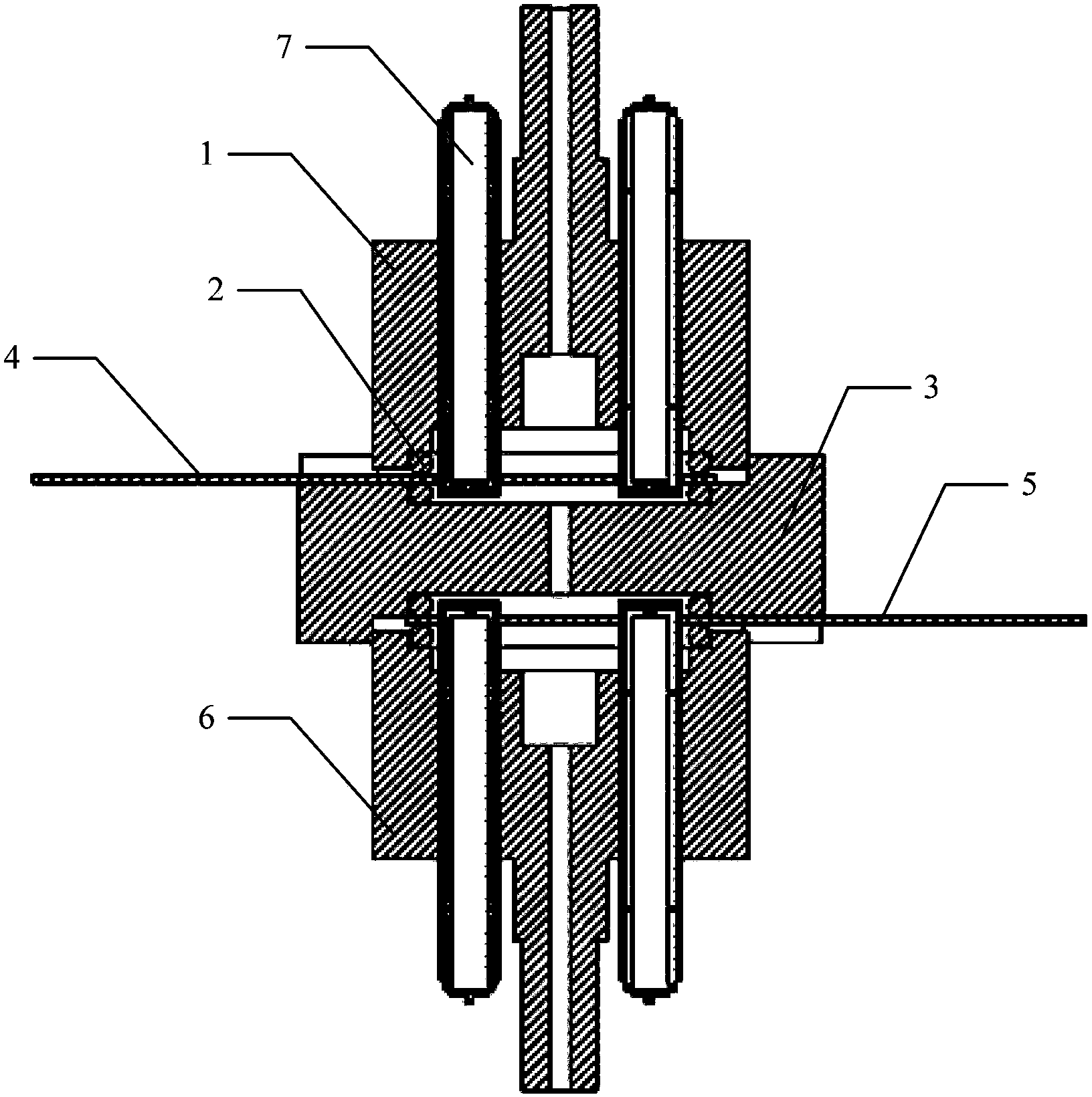

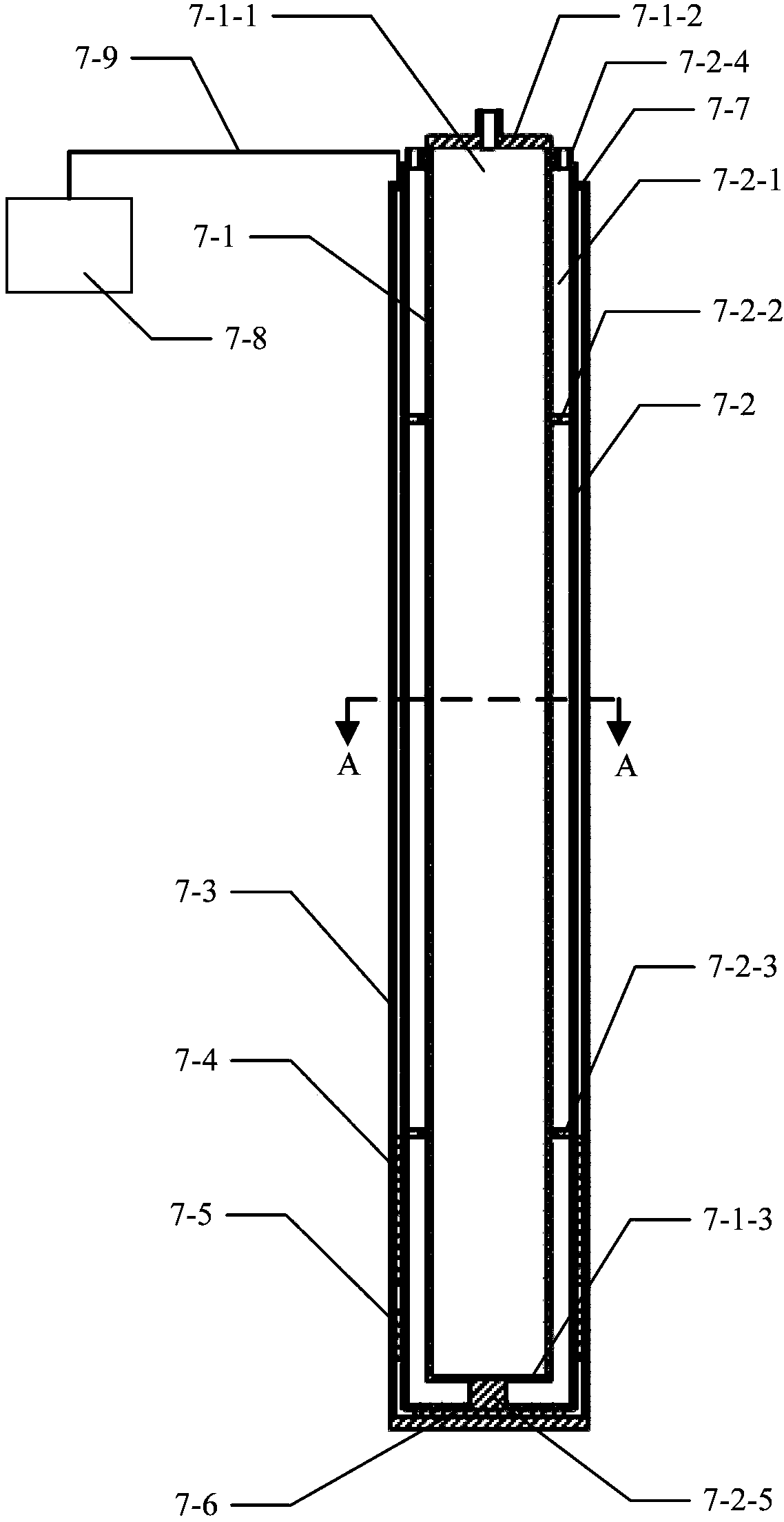

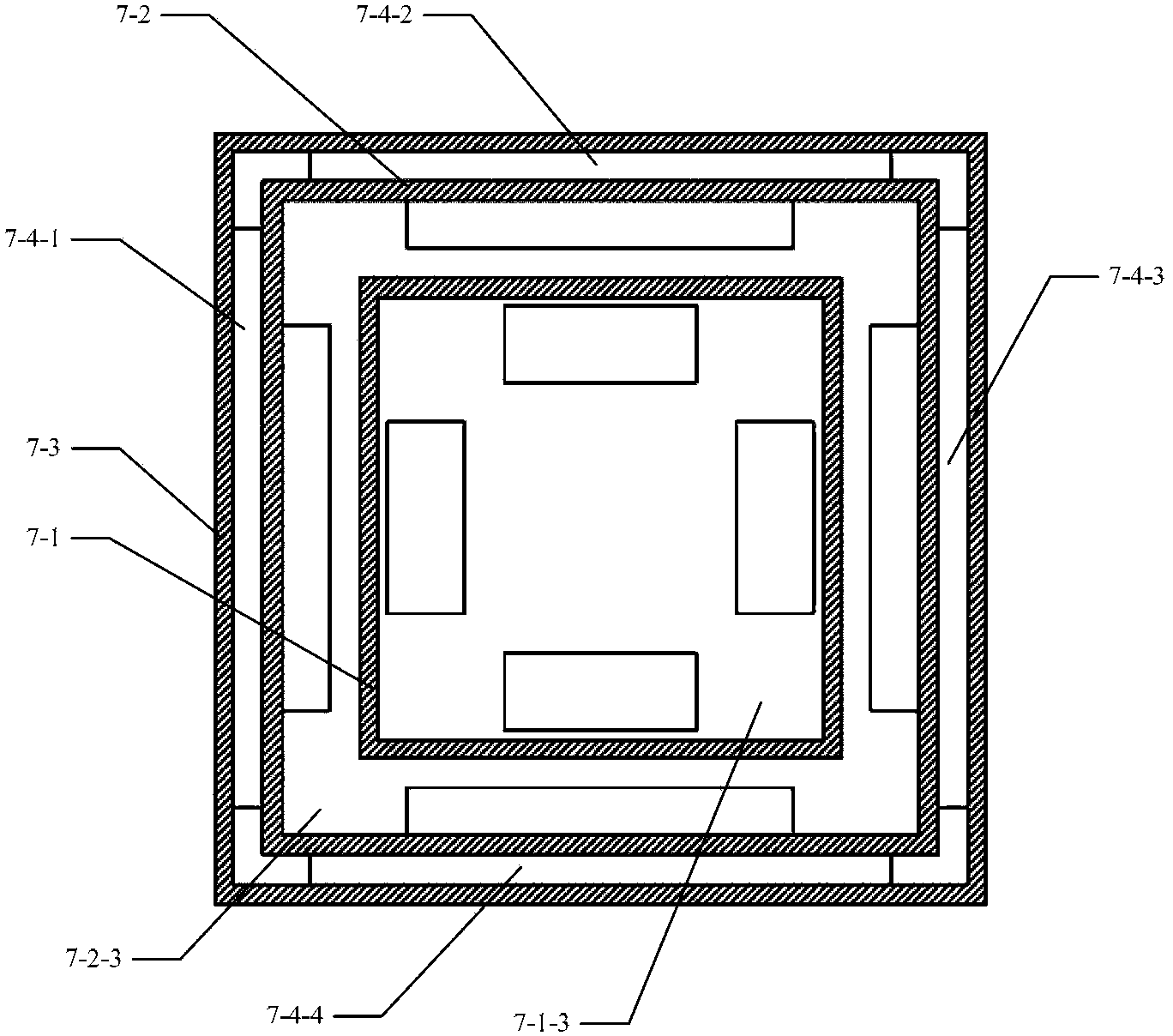

[0019] see figure 1 , Figure 5 and Figure 4 Shown, a kind of pulsed electric field treatment chamber comprises a treatment chamber upper mold 1, a sealing ring 2, a treatment chamber 3, an upper electrode 4, a lower electrode 5, a treatment chamber lower mold 6 and a semiconductor cooling device 7; a treatment chamber upper mold 1 and The lower mold 6 of the processing chamber has a similar platform structure, and its interior has a three-level stepped groove structure from the center to both ends; the upper mold 1 of the processing chamber and the lower mold 6 of the processing chamber are respectively in contact with the processing area 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com