Buffer valve structure

A buffer mechanism and valve technology, which is applied in the direction of the valve housing structure, balance valve, valve device, etc., can solve problems such as blockage of the connecting device, medium affecting the safety of the connecting device, etc., and achieve the effect of improving safety and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

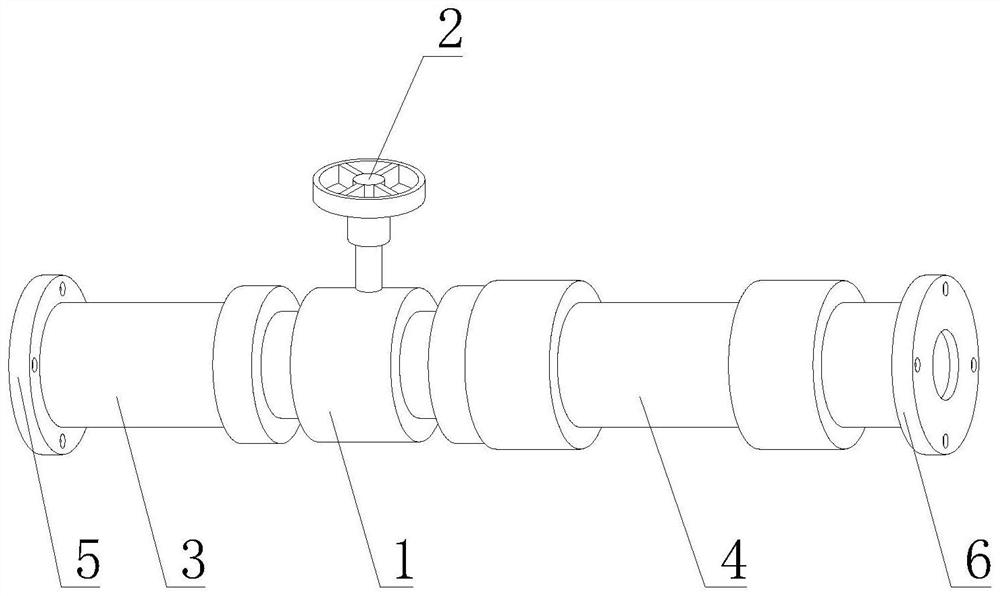

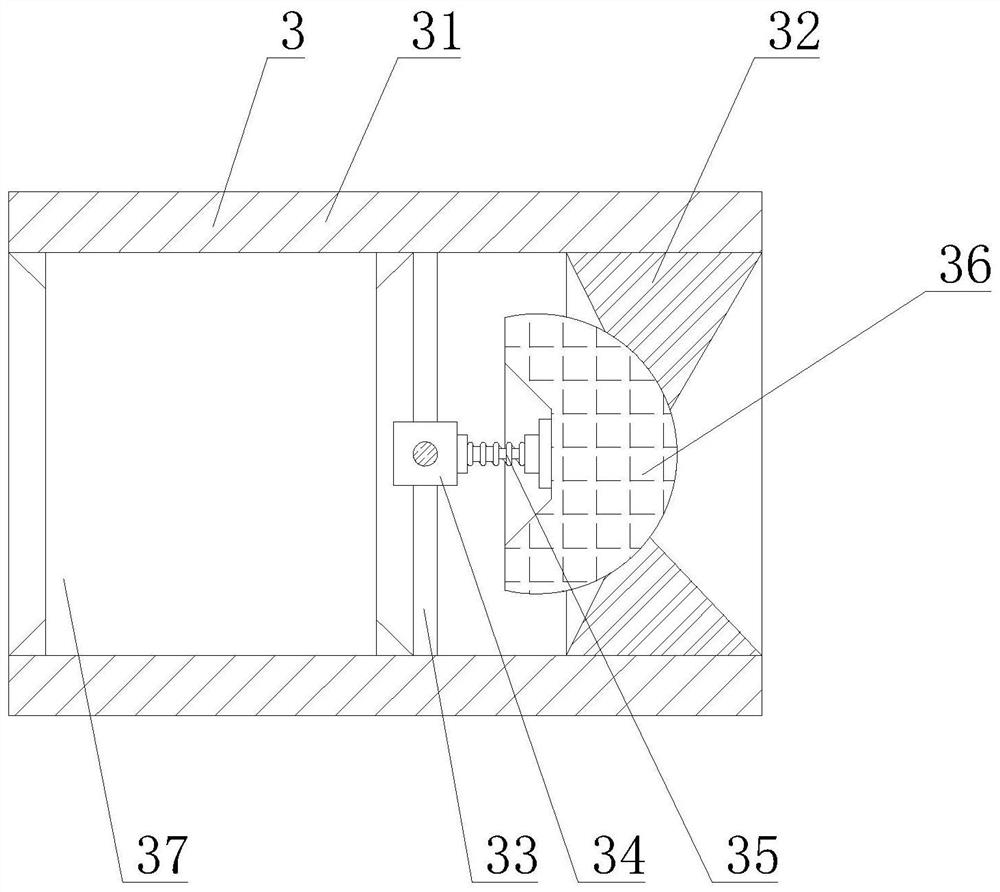

[0034] like Figure 1-8As shown, the present invention provides a buffer valve structure, comprising a valve body 1, a control handle 2 is arranged on the top of the valve body 1, a multi-stage buffer mechanism 3 is arranged on the left side of the valve body 1, and a right side of the valve body 1 is arranged A filter protection mechanism 4 is provided. The multi-stage buffer mechanism 3 includes a buffer tube body 31. The buffer tube body 31 is fixedly connected to the left side of the valve body 1. The left side of the buffer tube body 31 is fixedly welded with an output connection flange 5. The buffer tube The inner wall of the body 31 is fixedly welded with a fitting inner ring 32, and the inner wall of the buffer tube body 31 is fixedly welded with a fixing rod 33 located on the left side of the fitting inner ring 32, and one end of the fixing rod 33 away from the inner wall of the buffer tube body 31 is fixedly welded with a middle The position block 34, the right side ...

Embodiment 2

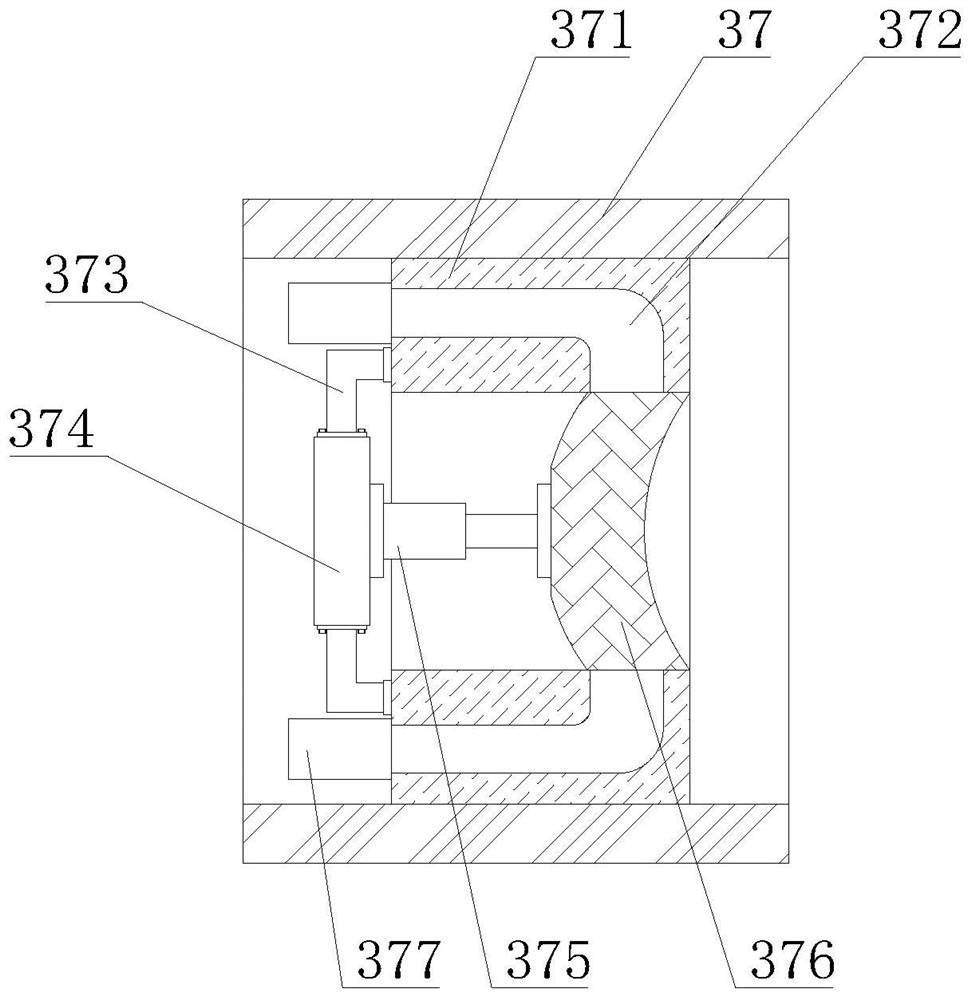

[0036] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a secondary buffer tube 37 is fixedly installed on the inner wall of the fitting inner ring 32, and a welded joint is fixed on the inner wall of the secondary buffer tube 37. In the inner ring 371, the inner wall of the welding inner ring 371 is provided with a buffer shunt groove 372, and the end of the buffer shunt groove 372 away from the inner wall of the welding inner ring 371 extends to the left side of the welding inner ring 371, and the left side of the welding inner ring 371 is fixedly welded with a Bending rod 373, one end of the bending rod 373 away from the welding inner ring 371 is fixedly mounted with a base plate 374, the right side of the base plate 374 is fixedly mounted with a fixing cylinder 375, and the left side of the welding inner ring 371 is fixedly connected to the left side of the buffer shunt 372. The branch buffer cylinder...

Embodiment 3

[0038] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a fixed bottom box 3771 is fixedly welded on the inner wall of the branch buffer cylinder 377, and a sliding protrusion is slidably connected to the inner cavity of the fixed bottom box 3771. Lifting block 3772, a silicone elastic block 3773 is fixedly installed on the inner wall of the fixed bottom box 3771, the side of the silicone elastic block 3773 away from the inner wall of the fixed bottom box 3771 is fixedly connected with the sliding protrusion block 3772, and the outer wall of the branch buffer cylinder 377 is fixedly installed There is an outstretching box 3774, an elastic foot 2 3775 is fixedly installed on the inner wall of the outreach box 3774, and a buffer closing plate 3777 is fixedly connected to the movable end of the elastic foot 2 3775, and the buffer closing plate 3777 extends away from the end of the second elastic foot 3775. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com