Driving circuit system of ultrasonic transducer and self-adaptive frequency modulation method

A driving circuit and ultrasonic technology, applied in electrical components, high-efficiency power electronic conversion, output power conversion devices, etc., can solve the problems of increasing difficulty of driving circuits, large number of components, and increased cost, and achieve less difficulty in hardware technology. , The effect of wide frequency adjustment range and small number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

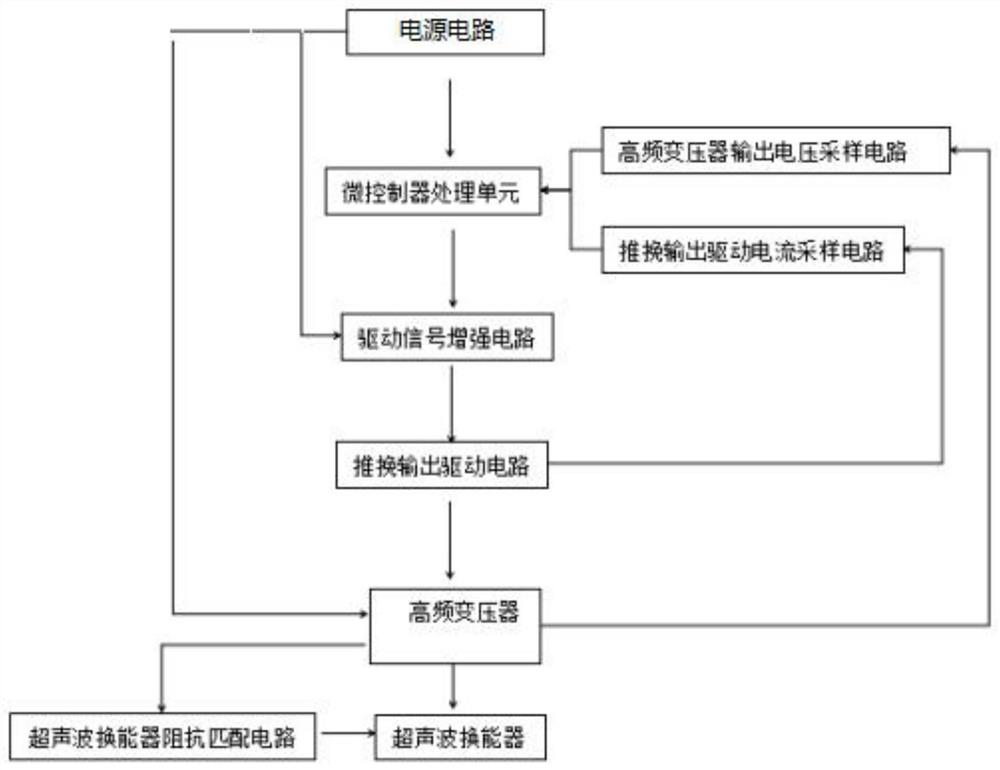

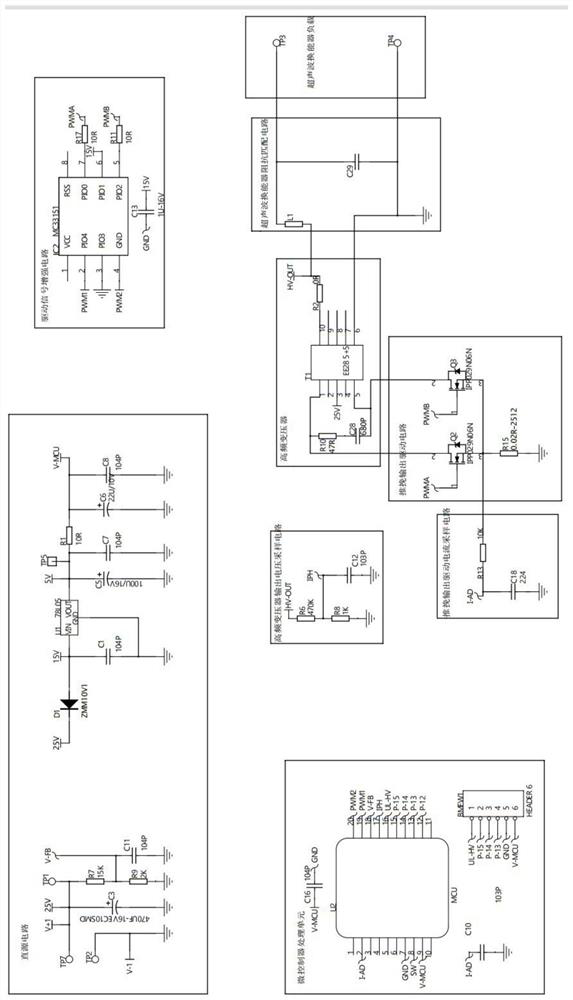

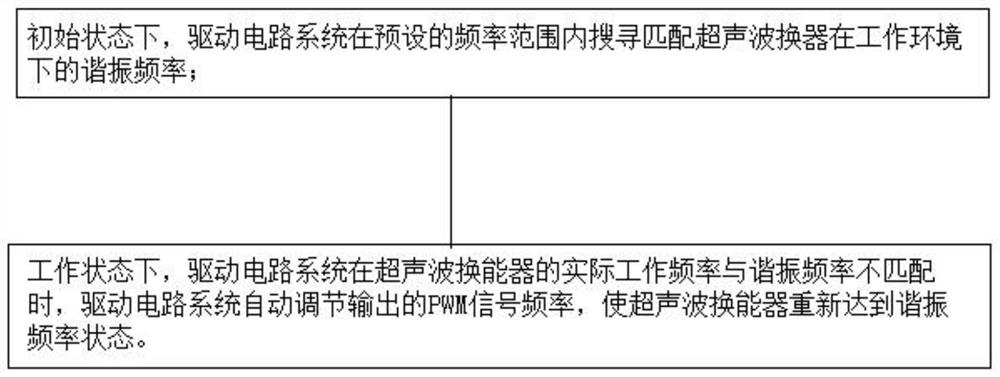

[0030] refer to Figure 1-3 , an embodiment provided by the present invention: a drive circuit system of an ultrasonic transducer, the drive circuit system is used to adjust the drive frequency of the ultrasonic transducer operation, so that the ultrasonic transducer works in the resonant frequency state , including a microcontroller processing unit, a drive signal enhancement circuit, a push-pull output drive circuit, a high-frequency transformer, an impedance matching circuit for an ultrasonic transducer, a push-pull output drive current sampling circuit, a high-frequency transformer output voltage sampling circuit, and a power supply circuit;

[0031] Microcontroller processing unit, real-time sampling of the working voltage of the ultrasonic transducer (that is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com