Electric power cabinet emergency protection device with fireproof and flame-retardant functions

A fire retardant, protective device technology, applied in the substation/distribution device enclosure, substation/switchgear cooling/ventilation, substation/switch layout details, etc., can solve problems such as fire spread, safety hazards, etc., to improve efficiency , reduce safety hazards and improve the effect of fire extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

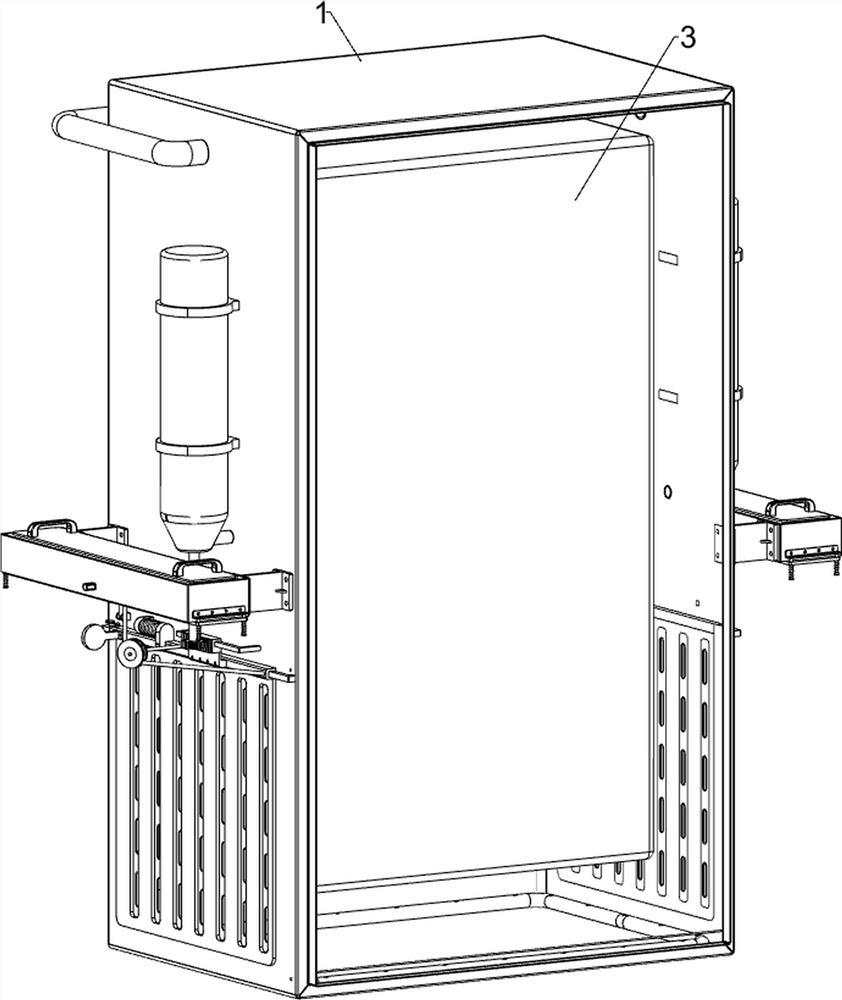

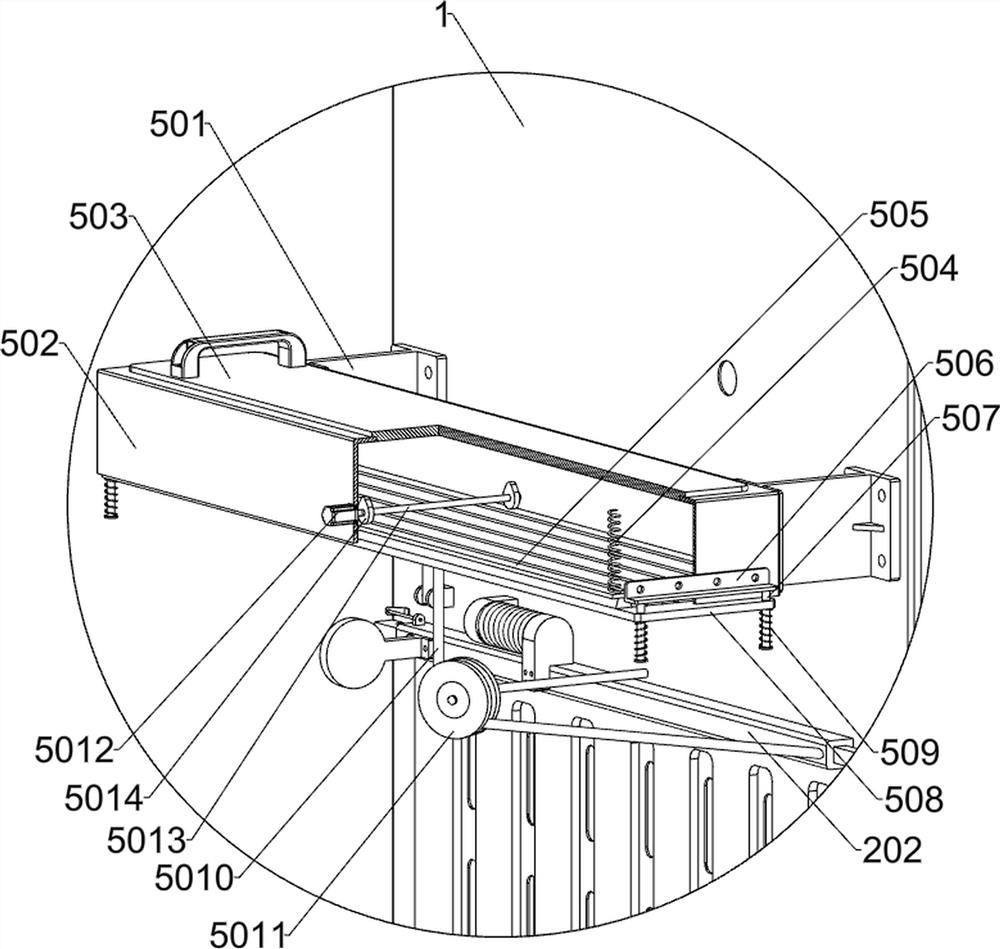

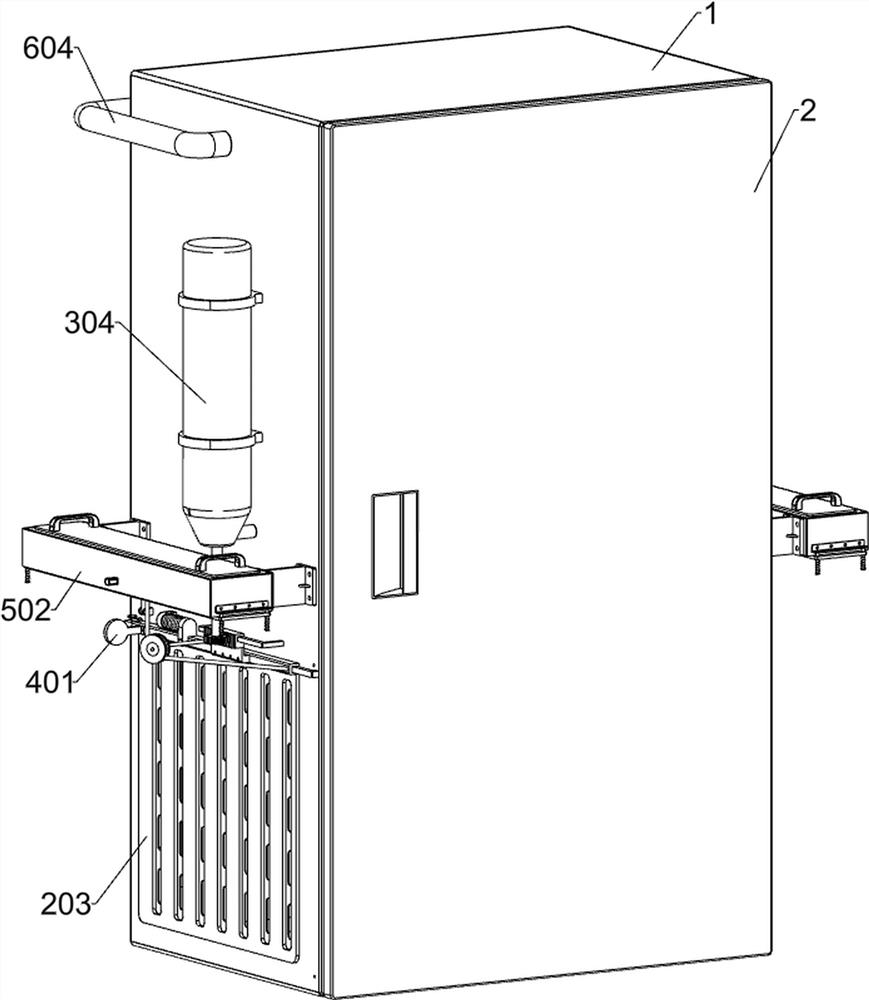

[0032] An emergency protection device for power cabinets with fire and flame retardant functions, such as Figure 1-11 As shown, it includes a box body 1, a box door 2, a power module 3, a closing component, an inflatable component, a fixing component and a fire extinguishing component; the box body 1 is installed with a box door 2 on the front side; the rear side of the inner wall of the box body 1 is installed with a power module 3; the lower part of the box body 1 is installed with a closing component; the upper left and right upper parts of the box body 1 are installed with an inflatable component; both the inflatable components are connected with the closing component; the left rear part and the right rear part of the box body 1 A fixed component is installed on each; both fixed components are connected with the closing component; a fire extinguishing component is installed in the left middle part and the right middle part of the box 1; the two fire extinguishing component...

Embodiment 2

[0039] On the basis of Example 1, as Figure 1-3 and Figure 12-13 As shown, it also includes a filter assembly, a filter assembly is installed at the rear of the box 1, and the filter assembly includes a second pipeline 601, a filter 602, a pump body 603, a third pipeline 604, a fourth pipeline 605 and a fifth pipeline 606 The upper part of the right side of the box body 1 is connected with a second pipeline 601; the right part of the rear side of the box body 1 is installed with a filter 602; the filter 602 is communicated with the second pipeline 601; The input end of the pump body 603 is communicated with the second pipeline 601; the output end of the pump body 603 is communicated with a third pipeline 604; A fifth pipe 606 is fixedly connected to the bottom of the inner side of the box body 1; the lower end of the third pipe 604 passes through the box body 1 and communicates with the fifth pipe 606; the fifth pipe 606 is provided with a number of small holes.

[0040] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com