Multi-axis scrubbing method and device

A technology of internal and rotating shafts in the device, which is applied in the field of washing, can solve the problems of excessive cleaning, insufficient brushing, and poor conformability of the surface of the cleaned items, so as to avoid excessive cleaning force, ensure the washing quality, and improve the washing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

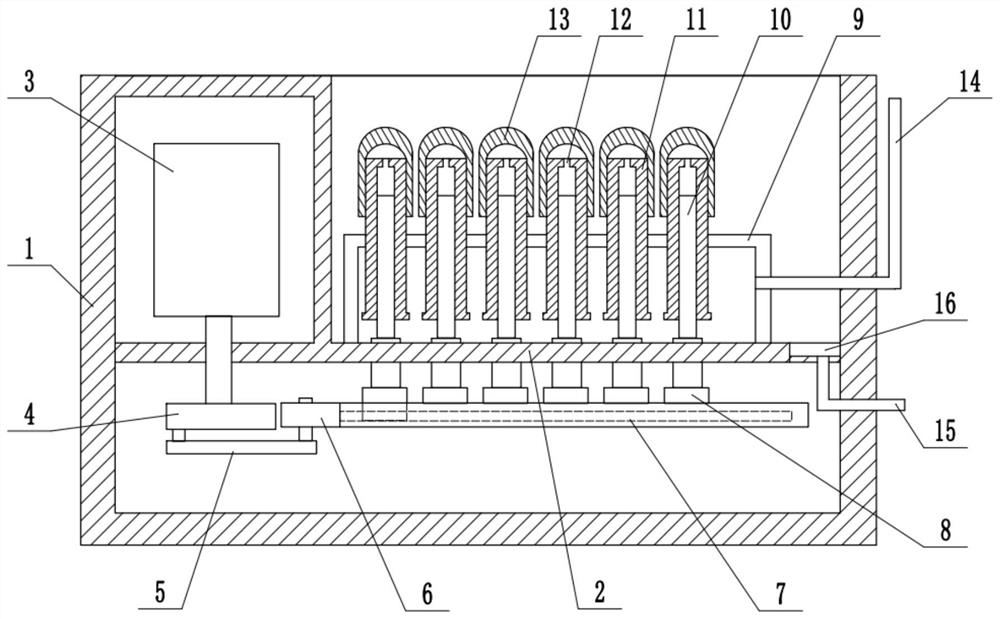

[0033] This embodiment provides a multi-axis brushing method, including:

[0034] S1. Put the items to be cleaned into the multi-axis brushing device; the multi-axis brushing device includes a body 1, a rotating shaft 10 and a floating assembly. There are multiple rotating shafts 10, and the multiple rotating shafts 10 are arranged in an array, and the floating assembly can be along the The rotating shaft 10 is axially slidably arranged on the rotating shaft.

[0035] S2. The floating component slides along the rotating shaft 10 under the action of the buoyancy of the cleaning solution to wrap the cleaned surface of the cleaned item. The floating assembly includes a sliding sleeve 11 and a blade brush 13 installed at the top of the sliding sleeve 11. When the floating assembly slides along the rotating shaft 10 under the buoyancy of the cleaning solution, the water tank 9 arranged in the body 1 enters the cleaning solution, so that the bottom end is located at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com