Battery replacement bracket for power battery of electric vehicle

A technology of electric vehicles and electric brackets, which is applied in the direction of electric vehicles, battery pack components, circuits, etc., can solve the problems of difficult replacement operations, heavy weight, and difficult full-box battery replacement applications, so as to improve wear resistance and The effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

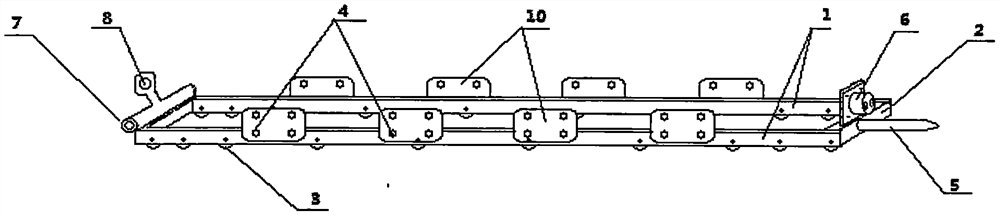

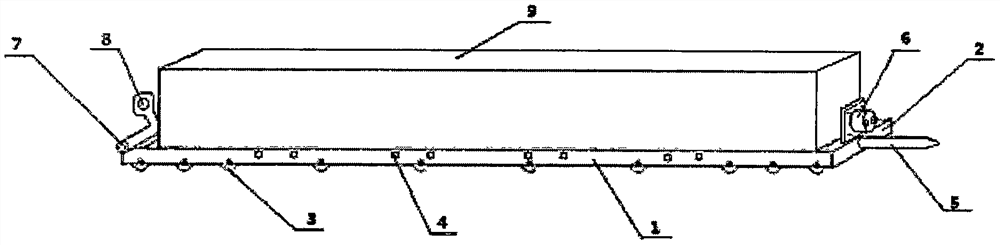

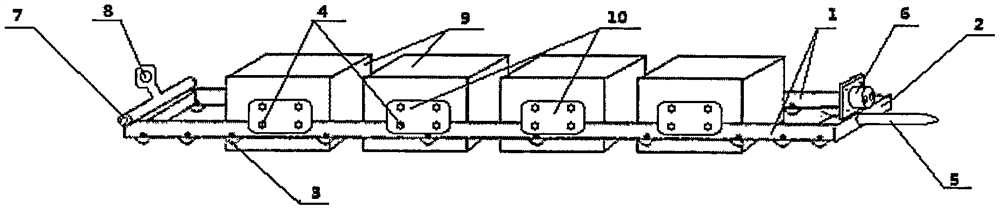

[0027] Embodiment A structure of an electric vehicle battery swap bracket is shown in the appendix. figure 1 shown.

[0028] Its structure is designed and manufactured as follows: a rectangular frame structure is welded by two longitudinal beams (1) and two transverse beams (2), wherein the longitudinal beam (1) is a C-shaped steel profile, with the C port facing down, and rows of load-bearing are installed. The rollers (3), in practice, the distribution of the rollers (3) should be closely arranged at both ends in order to reduce noise and durability. Positioning and mounting holes (4) of the power battery box (9) are also arranged on the longitudinal beam (1), and the number and spacing of the holes are specifically set by the number and spacing of the battery boxes. One end of the bracket is installed with a vertical positioning pin (5) and an electrical connector (6), and the other end of the bracket is installed with a horizontal transverse positioning pin hole (7) and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com