Full-automatic foundation pile integrity testing force hammer

A complete and fully automatic technology, applied in the testing of infrastructure, infrastructure engineering, construction, etc., which can solve the problems of increasing wavelength, decreasing reflected wave intensity, and low resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

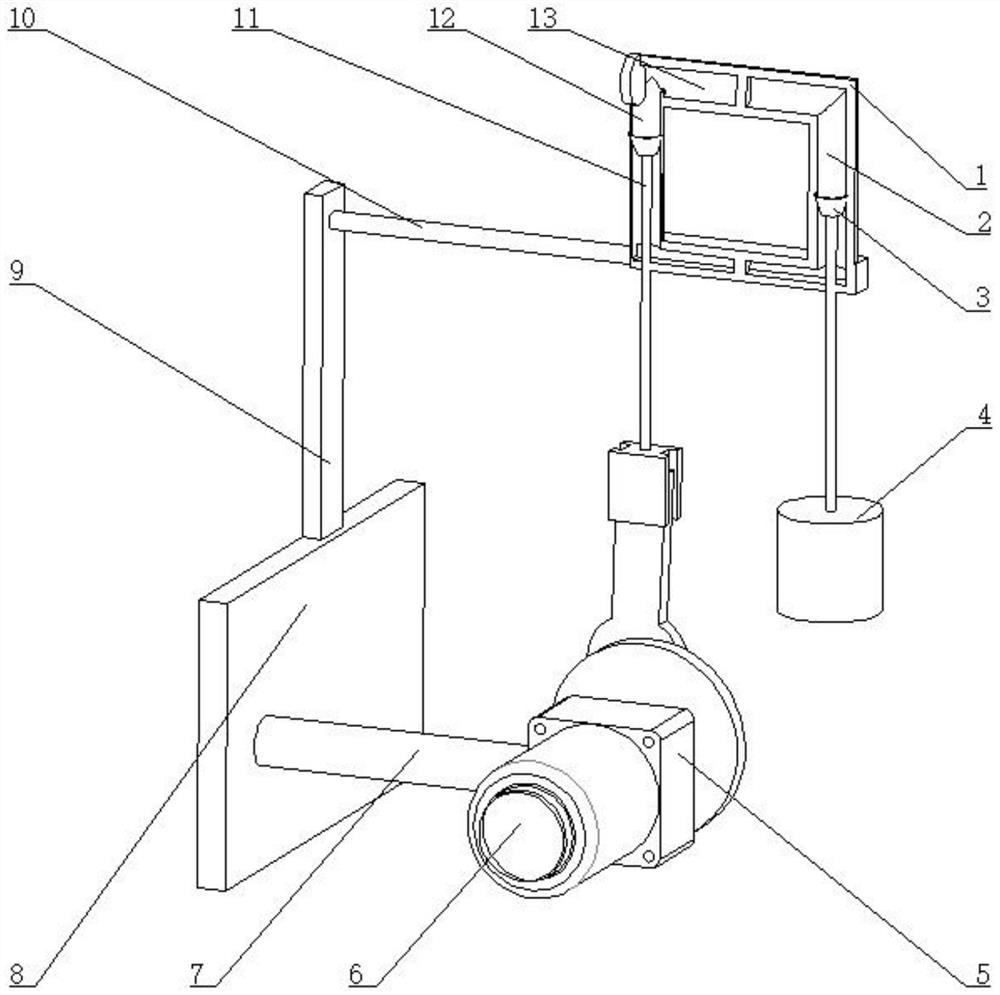

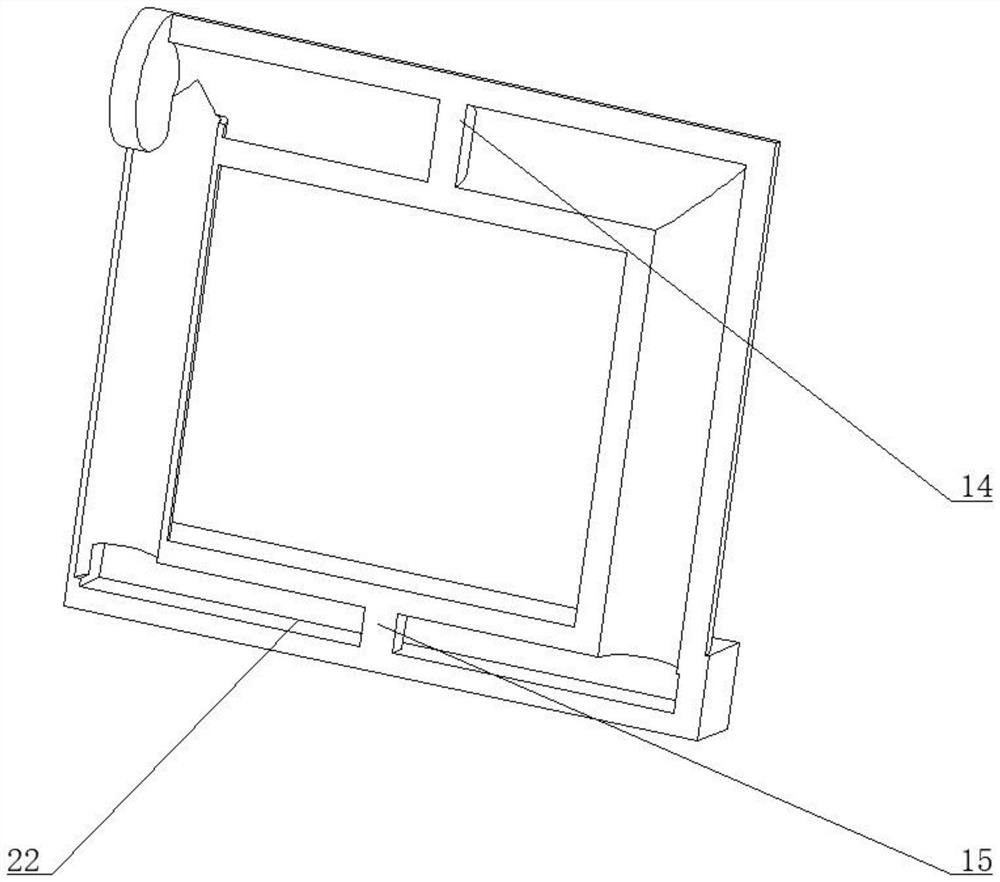

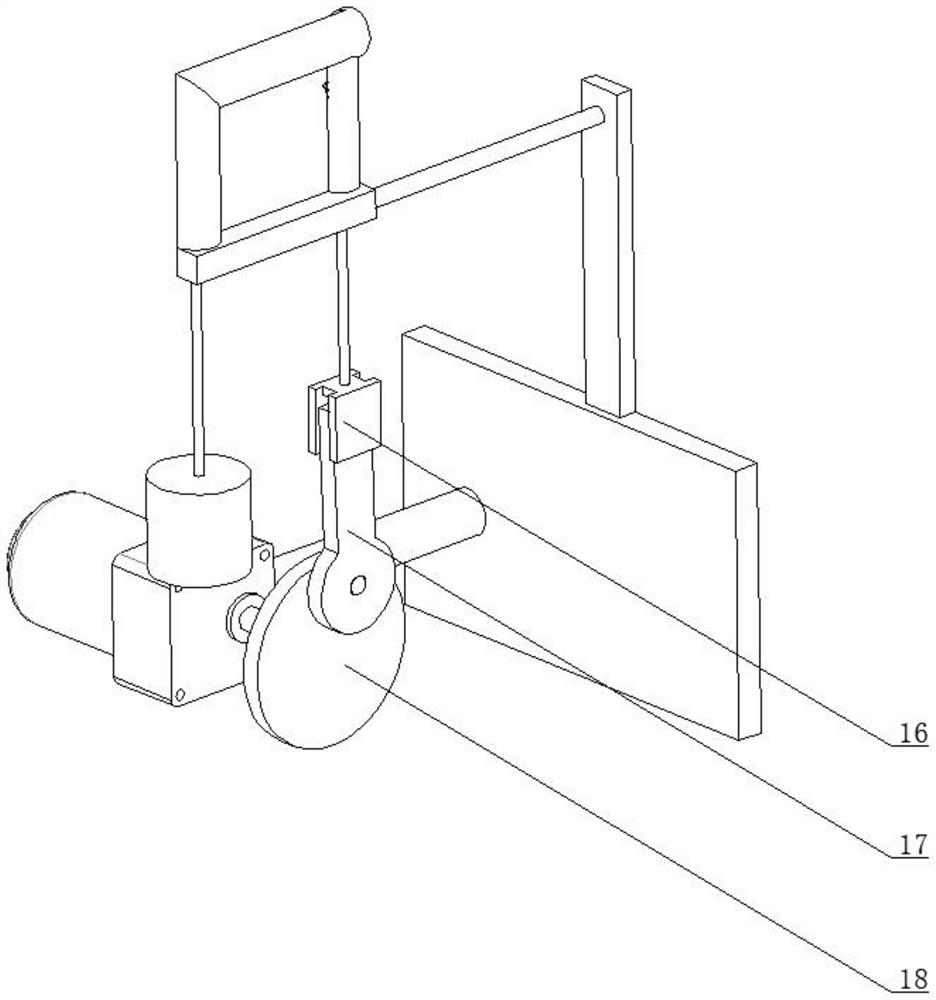

[0029] like Figure 1-Figure 5 As shown, the present invention includes a mounting plate 8, the mounting plate 8 is fixedly connected to a round rod 7, the round rod 7 is fixedly connected to the reducer 5, the mounting plate 8 is fixedly connected to a vertical rod 9, and the vertical rod 9 The second round rod 10 is fixedly connected, and the second round rod 10 is fixedly connected to the cylinder 1. The cylinder 1 is provided with a working cylinder 2, a compression cylinder 12, an upper air passage 13 and a lower air passage 22, and the working cylinder 2 communicates with the The upper air passage 13 and the lower air passage 22, the compression cylinder 12 communicates with the upper air passage 13 and the lower air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com