Solidifying agent for composite heavy metal polluted soil and its preparation and application method

A technology of heavy metal polluted soil and curing agent, applied in chemical instruments and methods, restoration and application of polluted soil, etc., can solve the problems of high greenhouse gas emissions, changing soil structure, high energy consumption of cement, etc., to reduce infiltration volume, increase adsorption, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

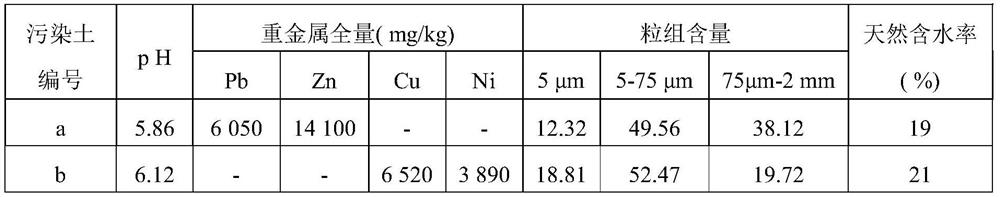

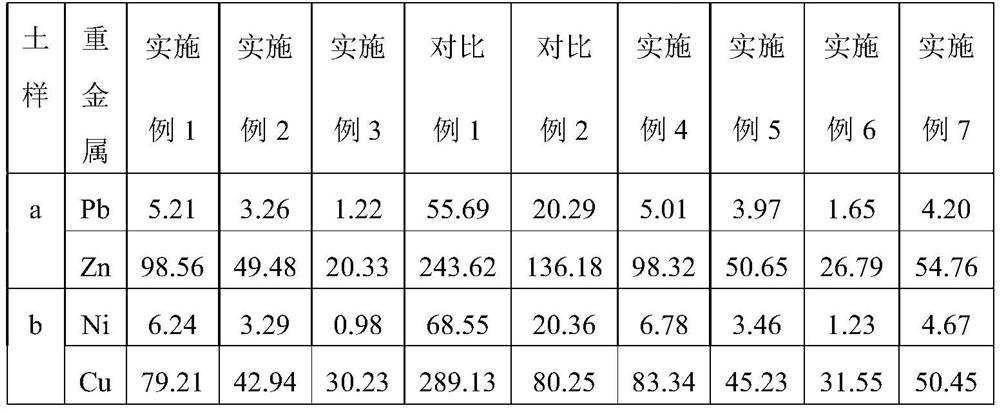

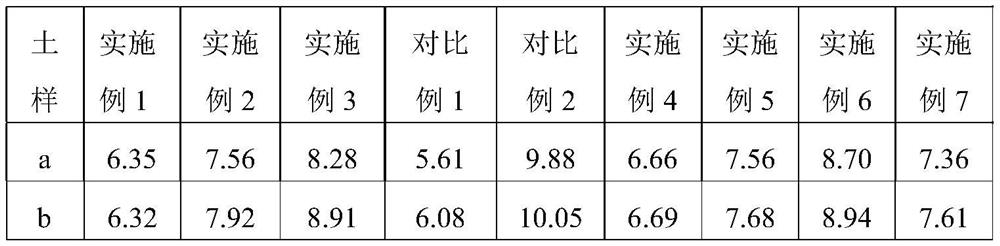

Examples

Embodiment 1

[0027] The solidifying agent for compounding heavy metal polluted soil of the present invention is composed of the following materials in parts by mass: 45% of steel slag powder; 20% of light-burned magnesium oxide; and 35% of phosphate-activated bone powder.

[0028] The steel slag powder is activated steel slag powder prepared by the following method: the converter slag is subjected to magnetic separation and then crushed and screened; among the obtained products, materials with a particle size of less than 2 mm are placed in an oven and dried by air flow at a temperature of 105 ° C. Dry until the water content is 1%. The obtained product is ground and passed through a 200-mesh sieve, and then calcined in an electric furnace at 700°C for 2 hours. The basicity value of the steel slag powder is 2.07.

[0029] The main components and content of the steel slag are shown in Table 1. It should be noted that the steel slag used in the present invention is not limited to the data in...

Embodiment 2

[0042] The preparation process and curing process are the same as in Example 1, except that the dosage of the curing agent is 10% (the curing agent accounts for the dry weight of the heavy metal and organic compound polluted soil).

Embodiment 3

[0044] The preparation process and curing process are the same as in Example 1, except that the amount of curing agent is 15% (the curing agent accounts for the dry weight of the heavy metal and organic compound polluted soil).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com