Three-dimensional rotary-vane vacuum pump

A technology of rotary vane vacuum pump and vacuum pump, which is applied in the direction of rotary piston type/swing piston type pump parts, parts of pumping device for elastic fluid, pump elements, etc., which can solve the problem of affecting the service life of the pump body, large Heat, inconvenience and other problems, to achieve good heat dissipation and cooling effect, high efficiency, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

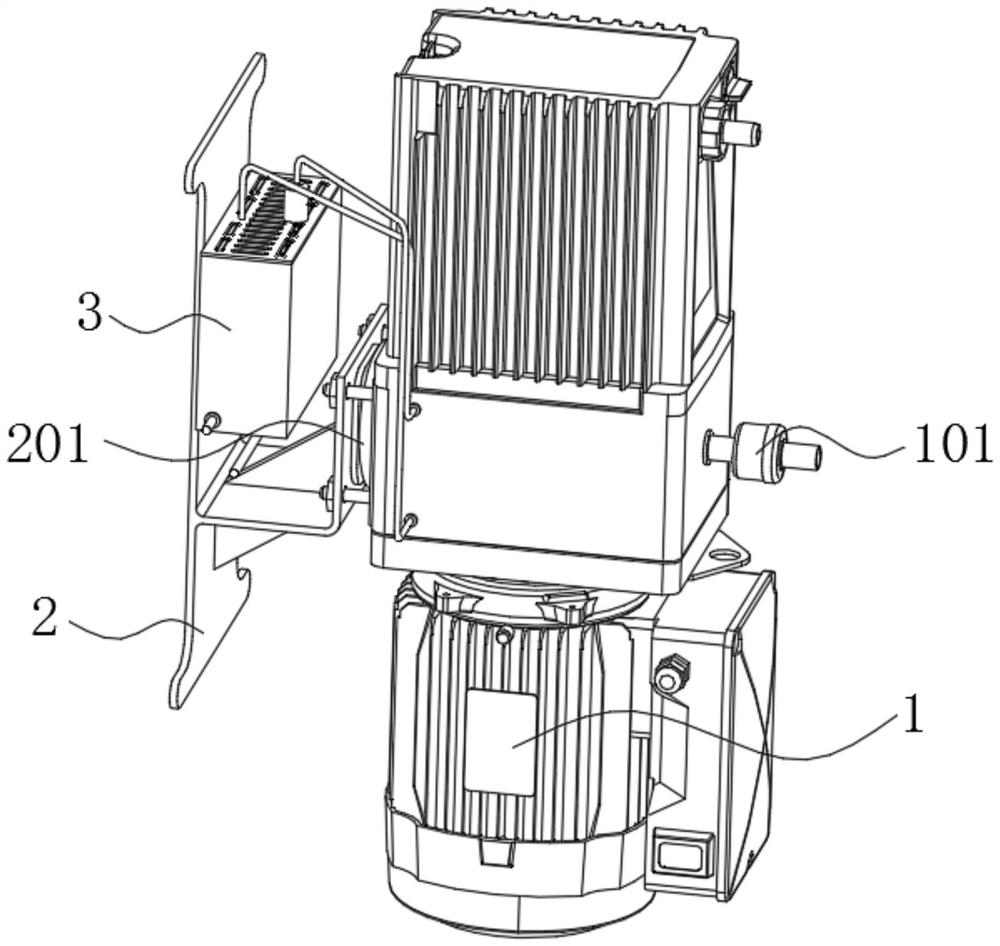

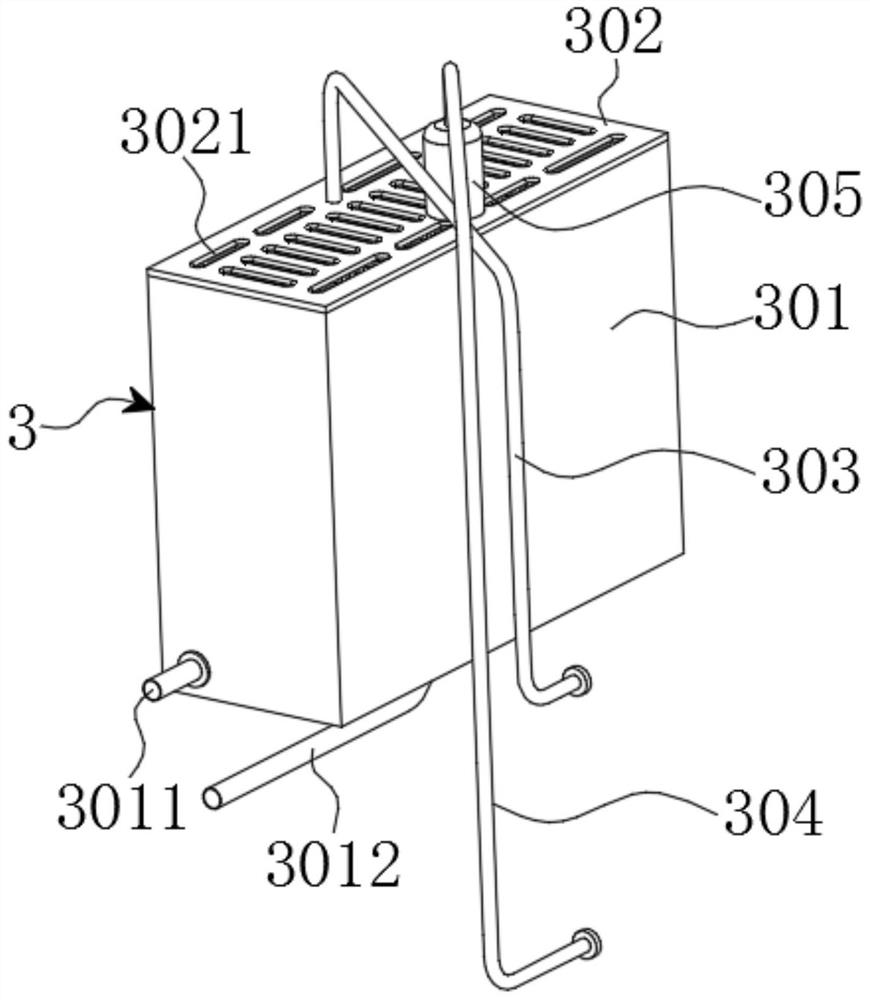

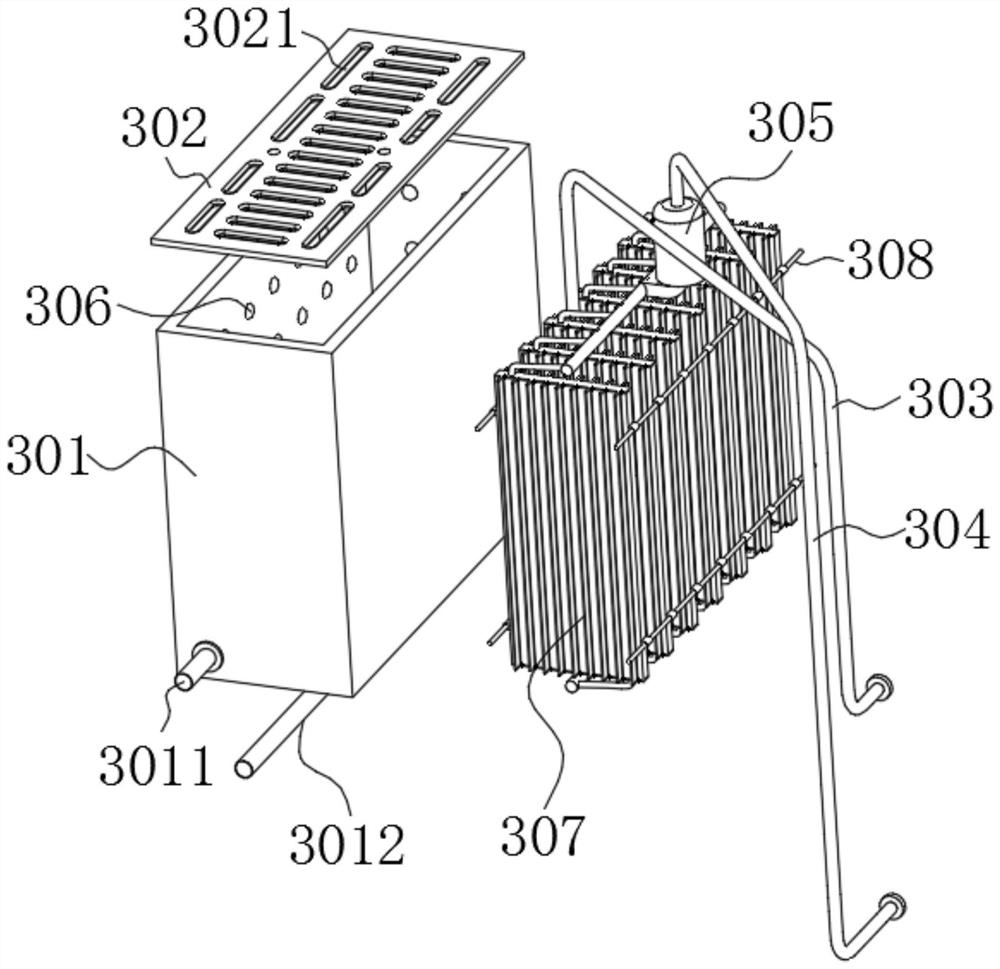

[0024] like figure 1 , figure 2 and image 3 As shown, an embodiment of the present invention proposes: a three-dimensional rotary vane vacuum pump, comprising a vacuum pump body 1 and a heat dissipation assembly 3, a bracket 2 is fixedly connected to one side of the vacuum pump body 1, and the setting of the bracket 2 is convenient for the entire The pump body is stably installed at the designated use position, which improves the stability of the entire vacuum pump during use and is easy to use. The heat dissipation component 3 is fixedly connected to the bracket 2. The setting of the heat dissipation component 3 is convenient for the vacuum pump to dissipate heat. Dissipate the heat generated in the pump body chamber, maintain the temperature of the pump body within a stable range, ensure that the vacuum pump can run stably for a long time, reduce the damage to the vacuum pump caused by high temperature, and prolong the service life of the vacuum pump. The box body 301 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com