Method for preparing ultra-light Fresnel lens

A Fresnel lens, ultra-lightweight technology, used in lenses, instruments, optics, etc., can solve the problems of weak reticle versatility, small processing aperture, large overlay error, etc., to increase the machinability and processing. The effect of contour accuracy, reduction of overlay errors, reduction of time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

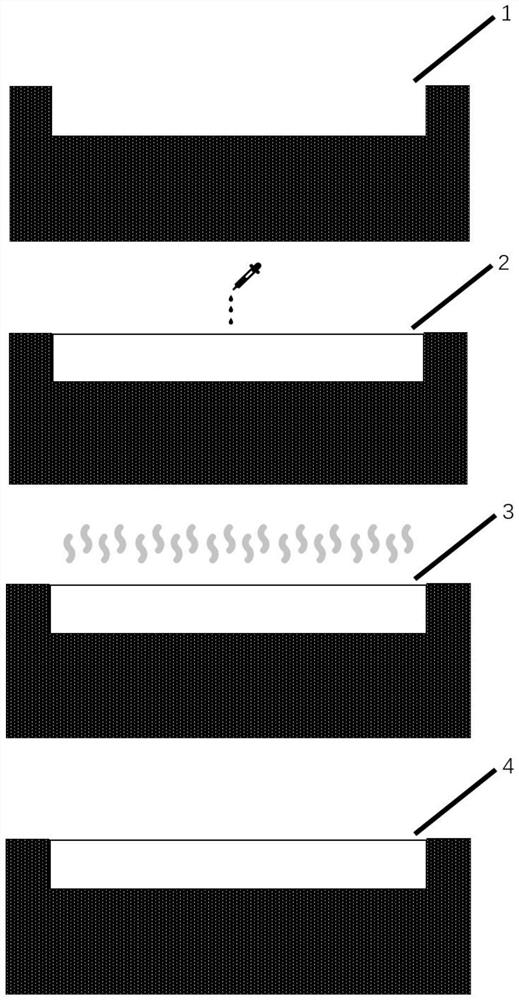

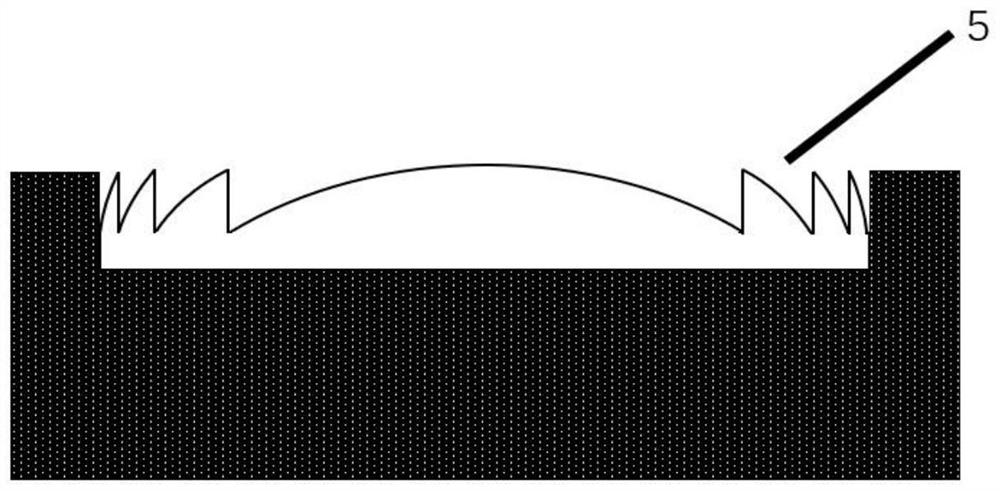

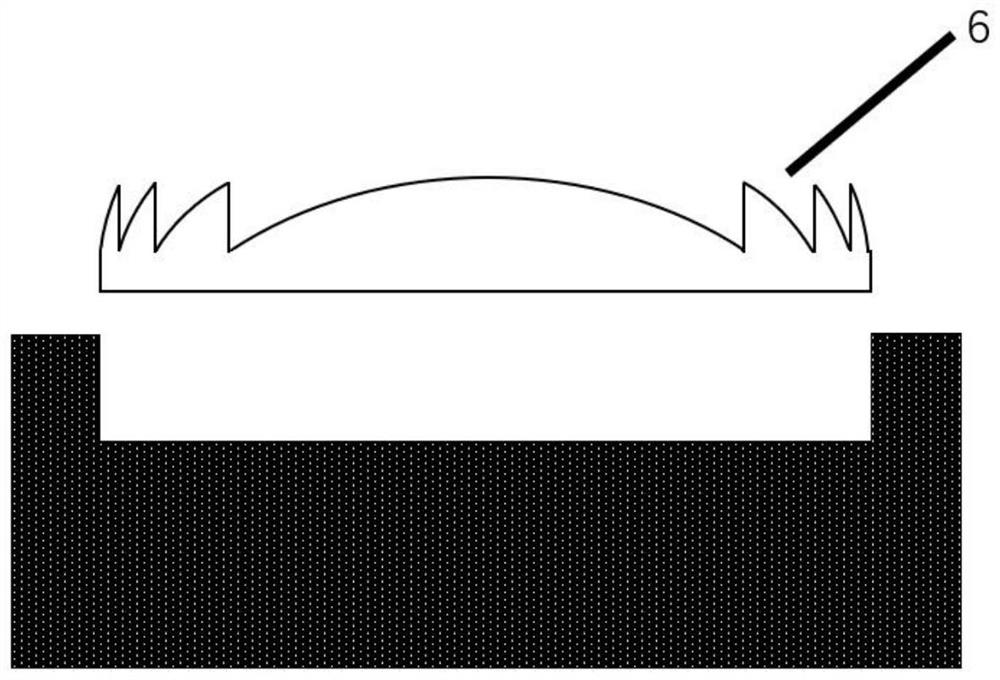

[0021] The present invention is a method for preparing an ultra-lightweight Fresnel lens, which includes three steps: the fabrication of an ultra-lightweight optical film and a rigid substrate composite, the contour processing of the ultra-lightweight Fresnel lens, and the ultra-lightweight Fresnel lens Stripping. Specifically, it includes rigid substrate 1, optical film material precursor solution coating 2, optical film material precursor solution curing 3, ultra-light optical film and rigid substrate composite 4, ultra-lightweight Fresnel lens contour processing 5, ultra-light Quality Fresnel lens 6. The workflow is to first process a rigid substrate with a smooth plane 1, then coat the surface of the rigid substrate with the optical film material precursor solution 2, and then cure the optical film material precursor solution 3 to form an ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com