Hot standby operation control method of fuel cell system, fuel cell system, storage medium and electronic device

A fuel cell system and operation control technology, applied in the direction of fuel cells, secondary batteries, circuits, etc., can solve the problems of power consumption, affecting the service life of the stack, reducing the service life of auxiliary electronic components, etc., to prolong the service life, Effect of enhancing life and reliability and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

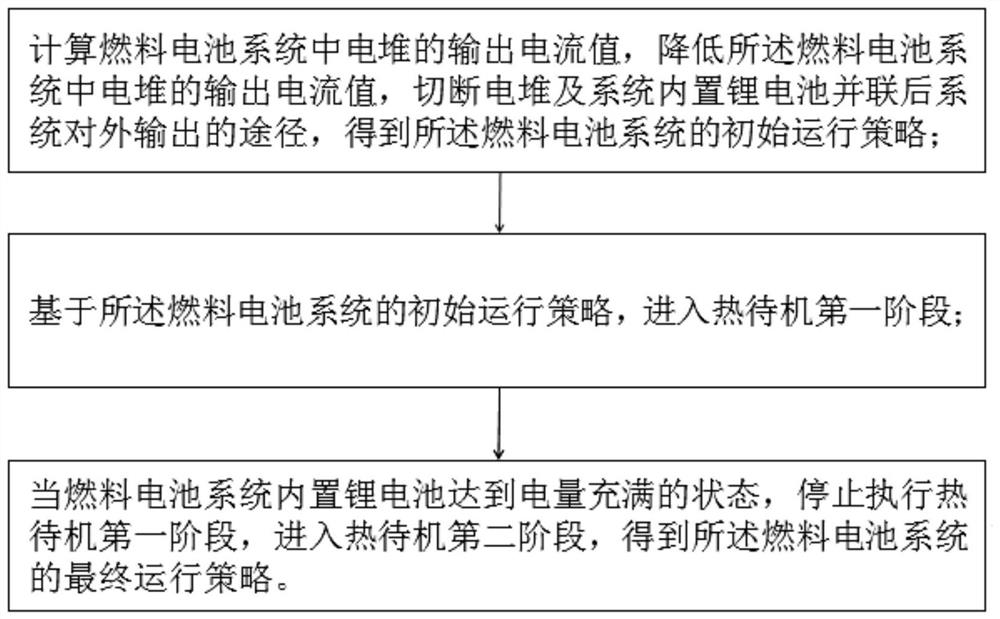

[0039] like figure 1 As shown, the present invention provides a hot standby operation control method of a fuel cell system, including:

[0040] Calculate the output current value of the stack in the fuel cell system, reduce the output current value of the stack in the fuel cell system, cut off the external output path of the system after the stack and the built-in lithium battery in the system are connected in parallel, and obtain the initial value of the fuel cell system. operating strategy;

[0041] Entering into the first stage of hot standby based on the initial operation strategy of the fuel cell system;

[0042] When the built-in lithium battery of the fuel cell system reaches a fully charged state, the execution of the first stage of hot standby is stopped, and the second stage of hot standby is entered, and the final operation strategy of the fuel cell system is obtained.

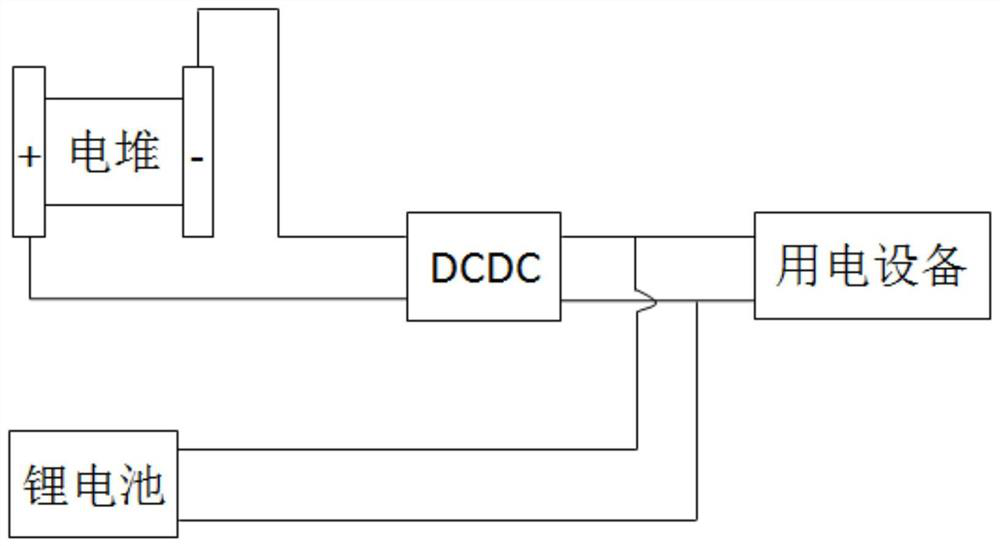

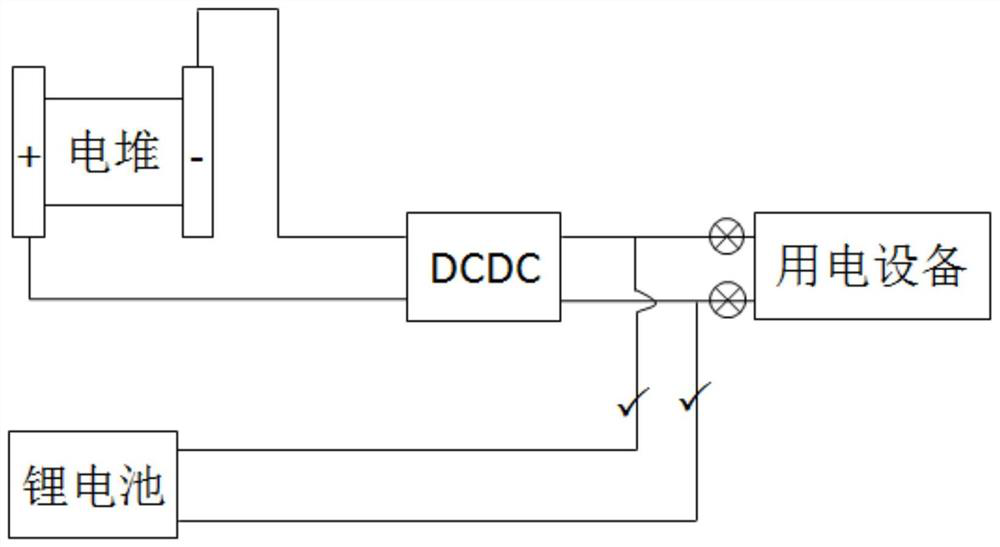

[0043] In specific implementation, as a preferred embodiment of the present invention, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com