Pipeline welding device with welding seam tracking function

A technology of tracking function and welding device, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve the effect of prolonging the stay time, tight connection and reducing vibration

Active Publication Date: 2022-06-10

苏州超莱斯机器人科技有限公司

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to overcome the shortcomings of the existing welding seam tracking welding equipment, the welding quality is not high, and it is easy to cause the gap in the welding position and the excessive bulge of the welding edge position, the present invention provides A pipeline welding device with seam tracking function

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

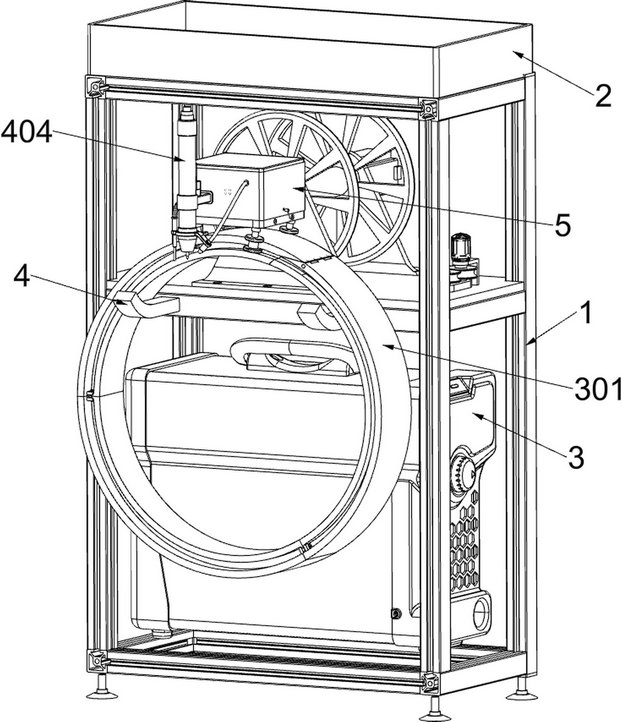

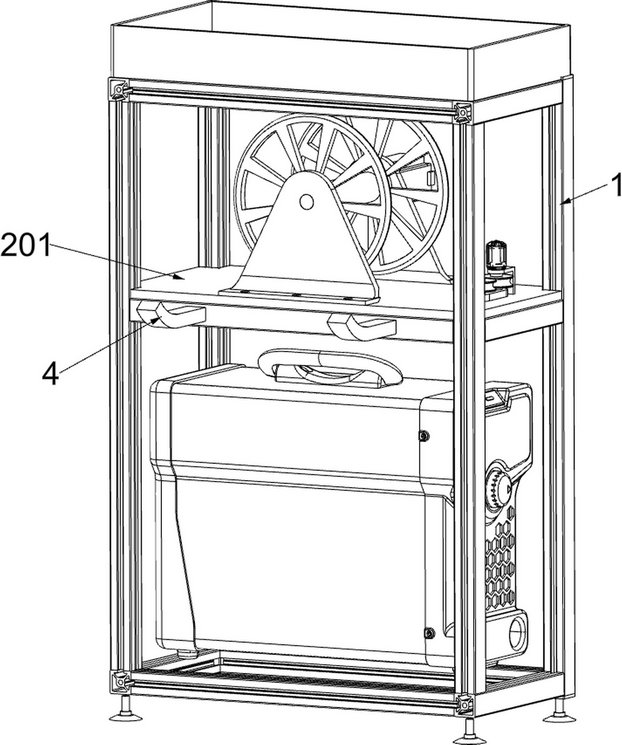

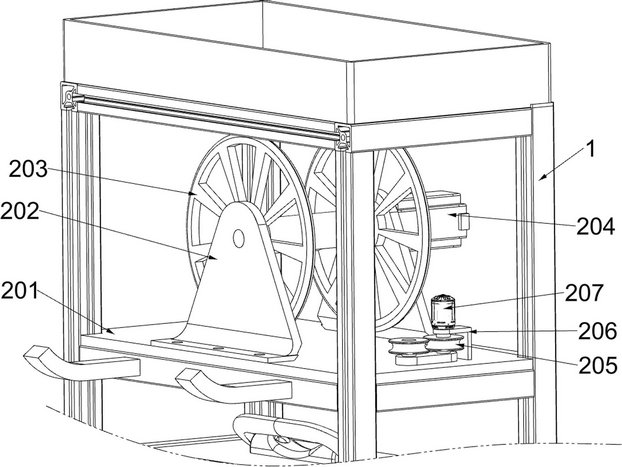

The invention relates to the field of welding, in particular to a pipeline welding device with a welding seam tracking function. The technical problems that an existing welding seam tracking welding device is not high in welding quality, and gaps in the welding position and excessive upheaval of the welding edge position are likely to be caused are solved. According to the technical scheme, the pipeline welding device with the welding seam tracking function comprises a fixed frame, a placing table and the like; a placing table is fixedly connected to the upper side of the fixing frame. Through the linkage effect of the linkage circular truncated cone and the swing plate, in the back-and-forth moving process of the welding gun, the staying time of the welding gun at the edge position of an annular welding seam is prolonged, and it is guaranteed that the edge position is tightly connected; the contact face of the hinged position of the first clamping plate and the second clamping plate is an inclined face, so that stable transition can be achieved between the first clamping plate and the second clamping plate, and shaking of the moving wheels walking at the hinged position of the first clamping plate and the second clamping plate is reduced.

Description

technical field [0001] The invention relates to the field of welding, in particular to a pipeline welding device with a seam tracking function. Background technique [0002] Existing Chinese patent CN104493335A discloses a kind of welding seam tracking device, and it fixes the welding workpiece on the welding machine frame, and the fast lifting device 1 drops the roller 17 and the welding torch 14 to the surface of the welding workpiece, at this time, the roller 17 and The welding workpiece remains in a contact state. When the surface of the workpiece rises, the workpiece lifts the roller 17 upwards, and at the same time drives the welding torch 14 to move upwards, keeping the welding distance between the welding torch 14 and the welding workpiece unchanged. The moving parts move down with the surface of the workpiece under the action of their own weight, thus ensuring that the roller 17 is always in contact with the welding workpiece; The distance is not equal and welding ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K9/127B23K9/133

CPCB23K9/127B23K9/133

Inventor 王正雨刘喜孙琥

Owner 苏州超莱斯机器人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com