Welding lathe for welding workshop

A technology for welding workshops and lathes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effects of convenient collection, enhanced fixing effect, and simplified fixing process

Inactive Publication Date: 2022-06-10

湖南省金峰机械科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the deficiencies of the prior art, the present invention provides a welding lathe for welding workshops, which has the advantages of being easy to adjust, and solves the problem of inconvenient adjustment of welding lathes for general welding workshops

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] Although the embodiments of the present invention have been shown and described, those skilled in the art can understand that various changes, modifications and substitutions can be made to these embodiments without departing from the principle and spirit of the present invention. and modifications, the scope of the invention is defined by the appended claims and their equivalents.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

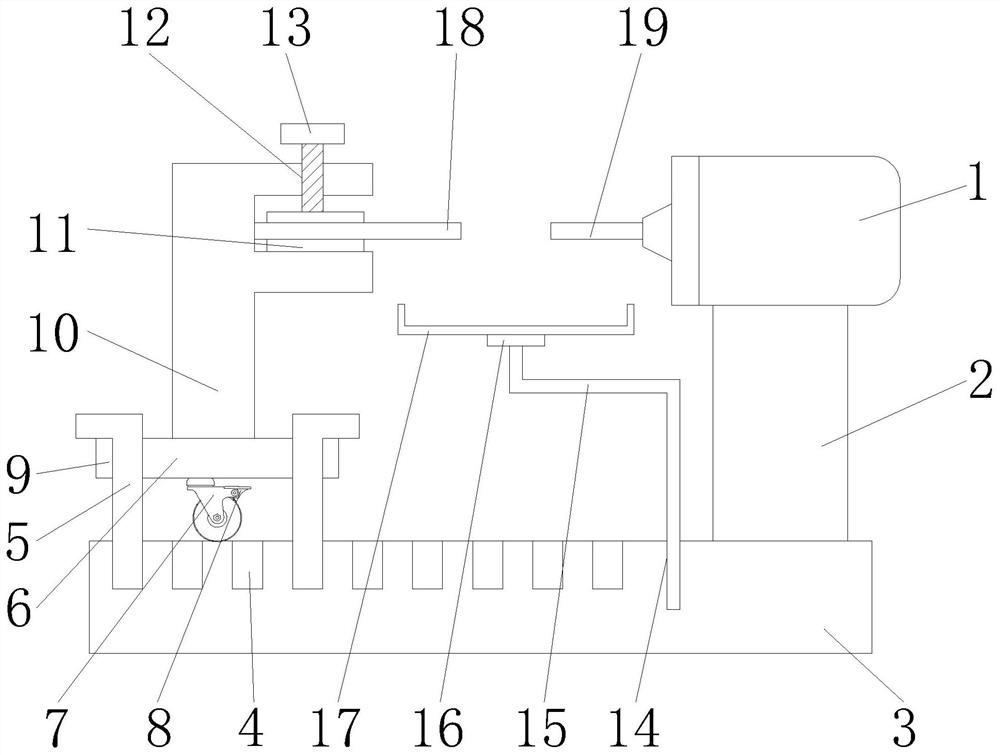

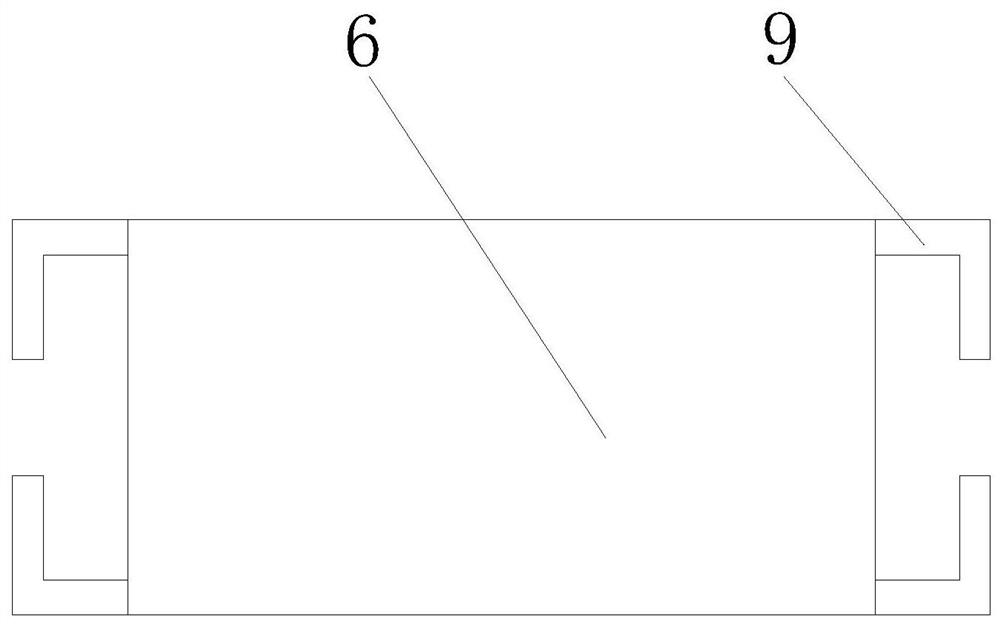

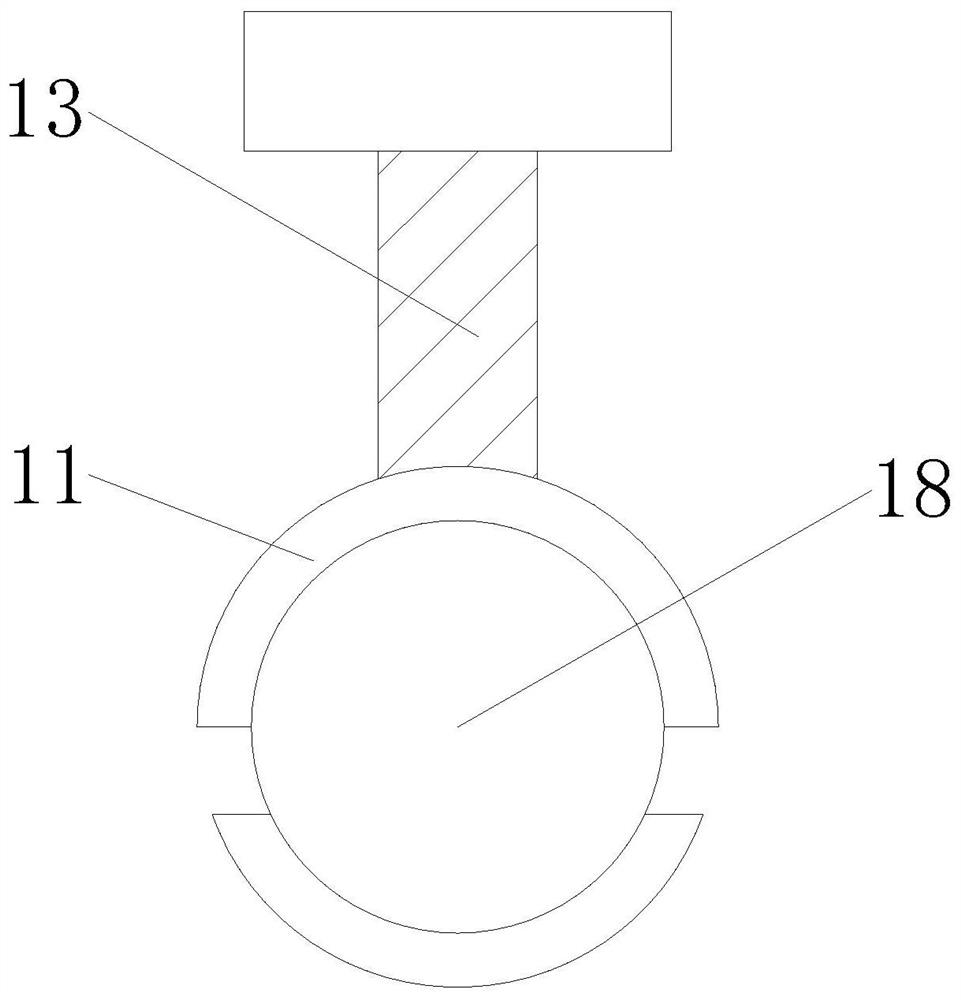

The invention relates to the technical field of welding lathes, and discloses a welding lathe for a welding workshop, which comprises a welding machine body, the bottom of the welding machine body is fixedly connected with a fixing frame, the bottom of the fixing frame is fixedly connected with a base, the top of the base is provided with a limiting groove, and the inner wall of the limiting groove is movably connected with a limiting block. And a pulley is movably connected to one side of the limiting block, a pulley is fixedly connected to the bottom of the pulley, a brake pad is fixedly connected to one side of the pulley, and a baffle is fixedly connected to one side of the pulley. According to the welding lathe for the welding workshop, the purpose of being convenient to adjust is achieved, the problem that a common welding lathe for the welding workshop is inconvenient to adjust is solved, the welding lathe can adapt to welding materials of different lengths, and therefore the applicability of the welding lathe is enhanced, daily welding work is facilitated, and the welding work efficiency is improved; and great convenience is brought to daily work of people.

Description

technical field [0001] The invention relates to the technical field of welding lathes, in particular to a welding lathe for welding workshops. Background technique [0002] Welding, also known as welding or welding, is a manufacturing process and technology for joining metals or other thermoplastic materials such as plastics by heating, high temperature or high pressure. There are many energy sources for modern welding, including gas flame, electric arc, Laser, electron beam, friction and ultrasonic, etc., in addition to being used in factories, welding can also be carried out in a variety of environments, such as the field, underwater and space, no matter where welding may bring danger to the operator, Therefore, appropriate protective measures must be taken when welding. [0003] Welding is widely used in daily life. For example, welding lathes are often used for welding work in welding workshops. However, welding lathes on the market often have the problem of inconvenien...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K37/00B23K37/053

CPCB23K37/00B23K37/053B23K37/0533

Inventor 朱洪春

Owner 湖南省金峰机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com