Packaging bag

A technology of packaging bags and composite materials, which is applied in the field of packaging bags, can solve the problems of low strength of plastic film, pollution of packaging bag products, and inconsistency with economic value, etc., and achieve the effects of large performance improvement, beautiful appearance, and improved tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

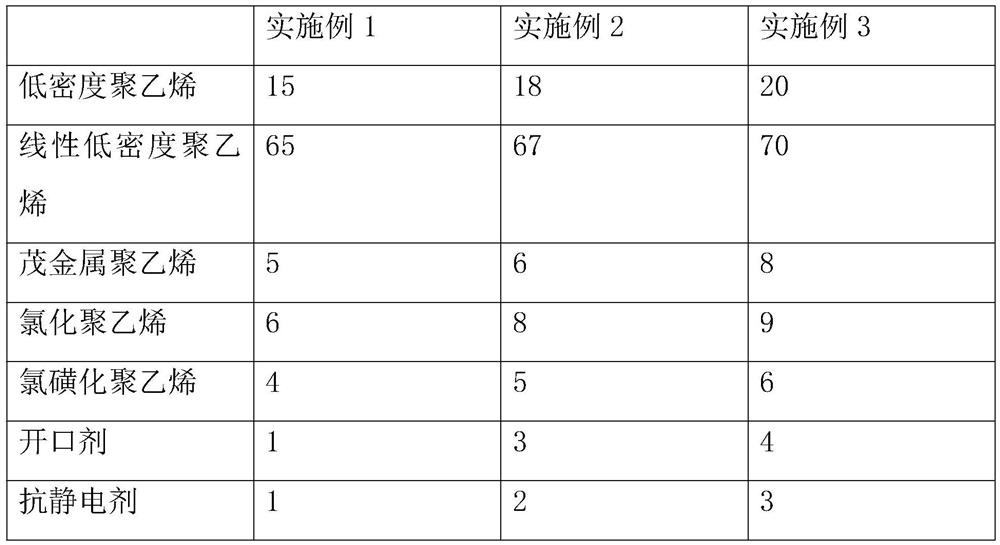

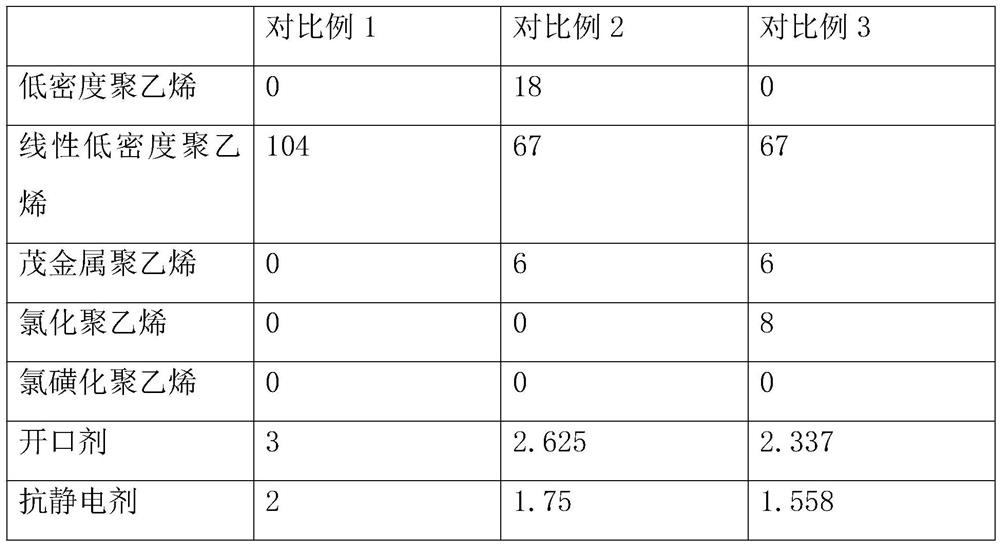

Embodiment 1

[0043] A packaging bag is blow molded from a thermoplastic composite material.

[0047]

[0049] The number-average molecular weight of the low-density polyethylene is 60,000, and the molecular weight distribution index is 3.

[0050] The number-average molecular weight of the linear low-density polyethylene is 70,000, and the molecular weight distribution index is 2.

[0051] The number-average molecular weight of metallocene polyethylene is 120,000, and the molecular weight distribution index is 2.5.

[0052] The number-average molecular weight of the chlorinated polyethylene is 100,000, the molecular weight distribution index is 4, and the chlorine content is 35%.

Embodiment 2、3

[0055] The number-average molecular weight of the low-density polyethylene is 70,000, and the molecular weight distribution index is 3.5.

[0056] The number-average molecular weight of the linear low density polyethylene is 80,000, and the molecular weight distribution index is 2.5.

[0057] The number-average molecular weight of the metallocene polyethylene is 160,000, and the molecular weight distribution index is 3.

[0058] The number-average molecular weight of the chlorinated polyethylene is 110,000, the molecular weight distribution index is 5, and the chlorine content is 36%.

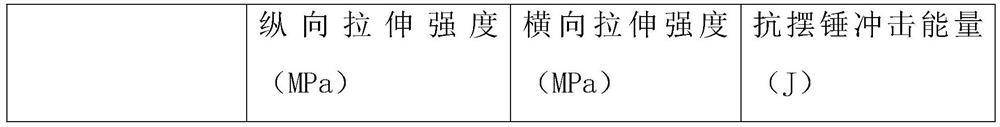

Embodiment 1-3

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com