Formula and preparation method of quick-drying hand feeling glue for improving artificial flower effect

A technology for imitating flowers and hand feeling, applied in artificial flowers, textiles, papermaking, clothing, etc., can solve the problems of being unsuitable for large-scale production, complex processing procedures, and high cost, and achieve fast drying speed, wide range of raw materials, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: A glue formulation that improves the quick-drying feel of the simulated flower effect, comprising component one and component two, wherein according to the following ratio: component one 1 and component two 2 parts, the component one comprising: TPE plastic.

[0020] The degree of TPE plastic is zero degrees.

[0021] The second component is dichloromethane or trichloromethane or tetrachloromethane.

[0022] Preparation method of a glue formulation that improves the quick-drying feel of the simulated flower effect, comprising the following steps:

[0023] Step 1: Pour the TPE plastic into component two, and then stir with a stick to get the mixed solution;

[0024] Step 2: Seal the mixed solution and then let stand for 2-10 h;

[0025] Step 3: Open the sealed mixture and stir again to get a glue that improves the quick-drying feel of the simulated flower effect.

Embodiment 2

[0026] Example TWO: A glue formulation that improves the quick-drying feel of the simulated flower effect, comprising component one and component two, wherein according to the following ratio: component one 1 and component two 11 parts, the component one comprising: TPE plastic.

[0027] The degree of TPE plastic is zero to minus one degree.

[0028] The second component is dichloromethane or trichloromethane or tetrachloromethane.

[0029] Preparation method of a glue formulation that improves the quick-drying feel of the simulated flower effect, comprising the following steps:

[0030] Step 1: Pour the TPE plastic into component two, and then stir with a stick to get the mixed solution;

[0031] Step 2: Seal the mixed solution and then let stand for 2-10 h;

[0032] Step 3: Open the sealed mixture and stir again to get a glue that improves the quick-drying feel of the simulated flower effect.

Embodiment 3

[0033] Example THREE: A glue formulation that improves the quick-drying feel of the simulated flower effect, comprising component one and component two, wherein according to the following ratio: component one 1 and component two 22 parts, the component one comprising: TPE plastic.

[0034] The degree of TPE plastic is five degrees.

[0035] The second component is dichloromethane or trichloromethane or tetrachloromethane.

[0036] Preparation method of a glue formulation that improves the quick-drying feel of the simulated flower effect, comprising the following steps:

[0037] Step 1: Pour the TPE plastic into component two, and then stir with a stick to get the mixed solution;

[0038] Step 2: Seal the mixed solution and then let stand for 2-10 h;

[0039] Step 3: Open the sealed mixture and stir again to get a glue that improves the quick-drying feel of the simulated flower effect.

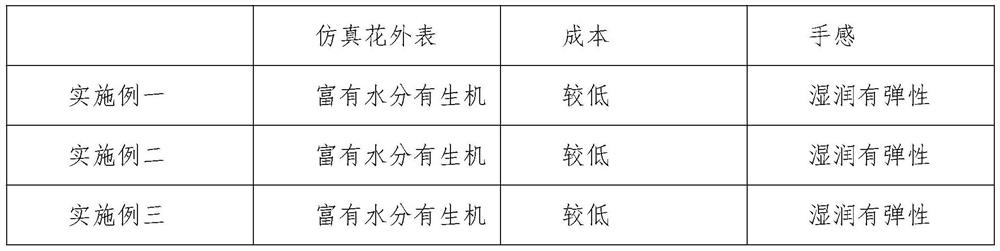

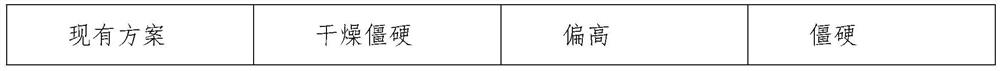

[0040] The following is a comparison table of flowers produced by the three sets of embodiments...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com