Server detection system automatic feeding system

An automatic feeding and detection system technology, applied in the direction of mechanical conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of low server detection efficiency, low server transportation efficiency, time-consuming and labor-consuming, etc., to improve detection Efficiency and transportation efficiency, the effect of improving detection efficiency and transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Attached to the following Figure 1-4 This application will be described in further detail.

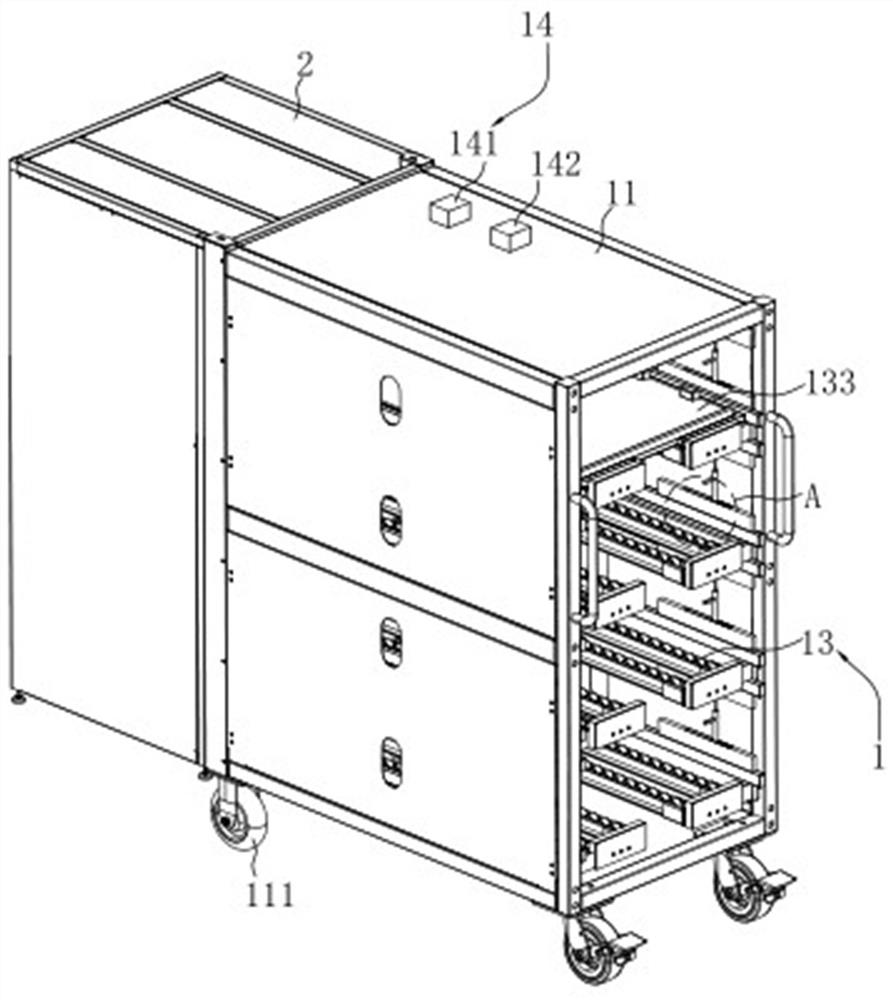

[0031] The embodiment of the present application discloses an automatic feeding system for a server detection system, which is used for transporting an assembled server. refer to figure 1 and figure 2 , the automatic feeding system of the server detection system includes an aging car mechanism 1 and a hoist 2. The aging car mechanism 1 is used to place the server, and is used to push several servers to the elevator 2 in turn, and the elevator 2 is set on the aging car mechanism. 1 side, the elevator 2 is used to sequentially receive the pushed servers.

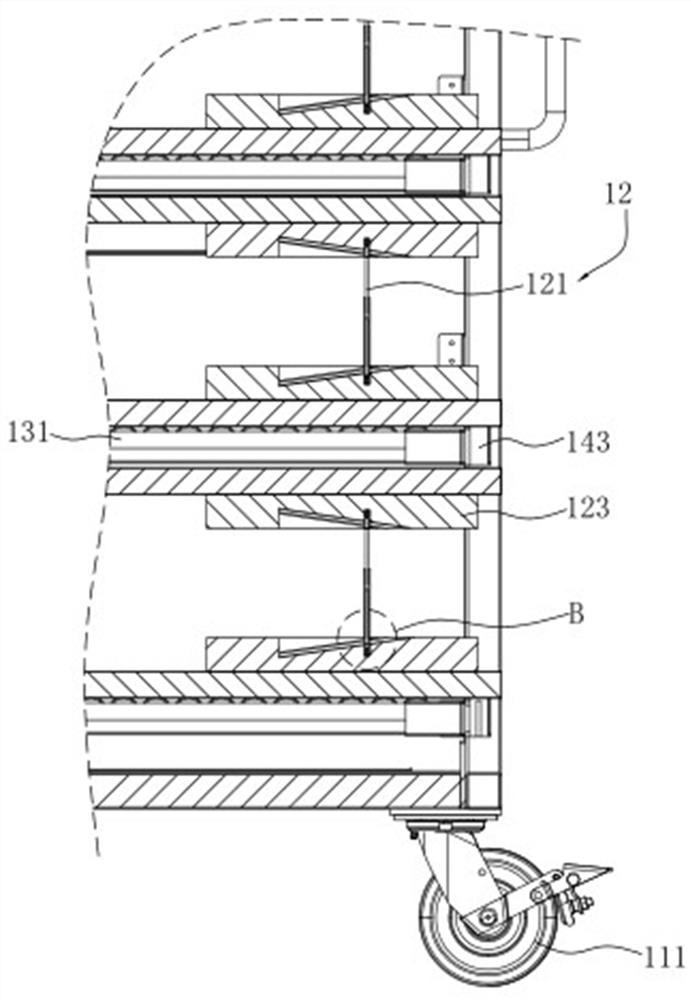

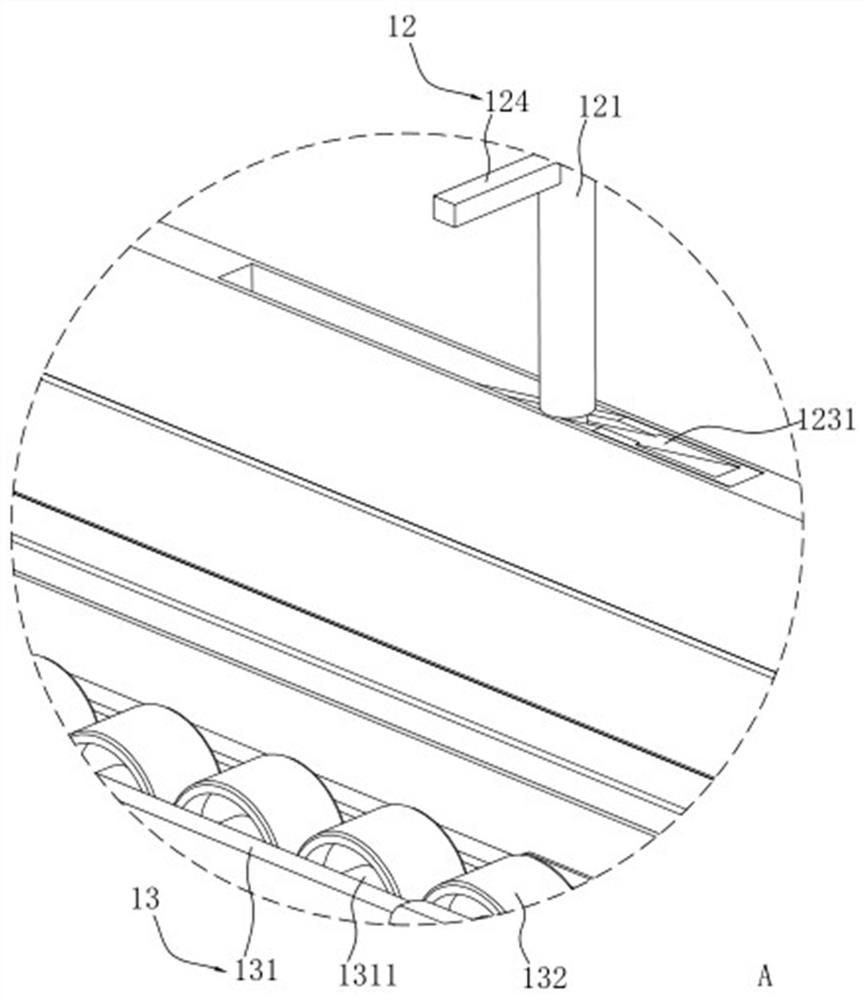

[0032] refer to Figure 1 to Figure 4, the aging car mechanism 1 includes an installation box 11, the installation box 11 is arranged vertically, both ends of the installation box 11 in the width direction are open structures, and the top corners of the bottom surface of the installation box 11 are installed with self-lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com