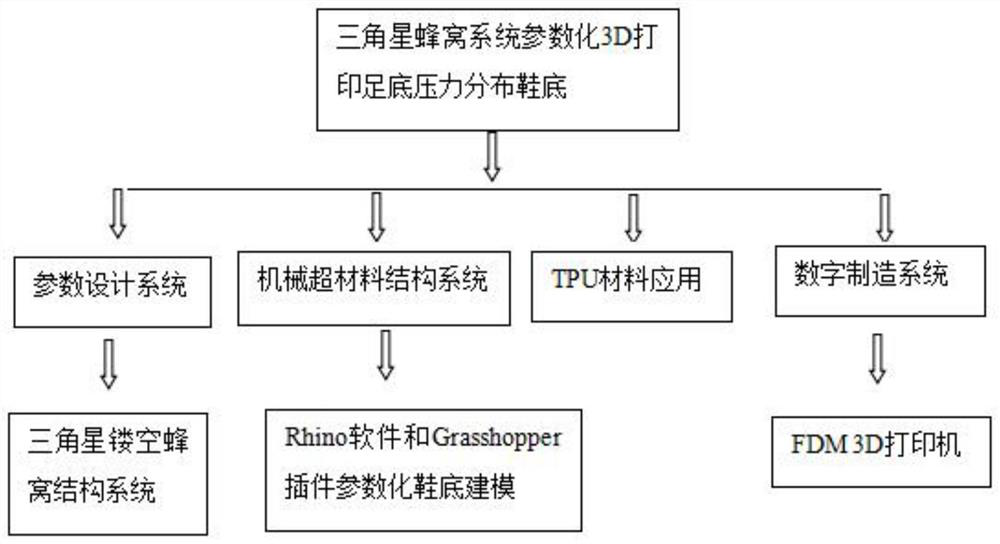

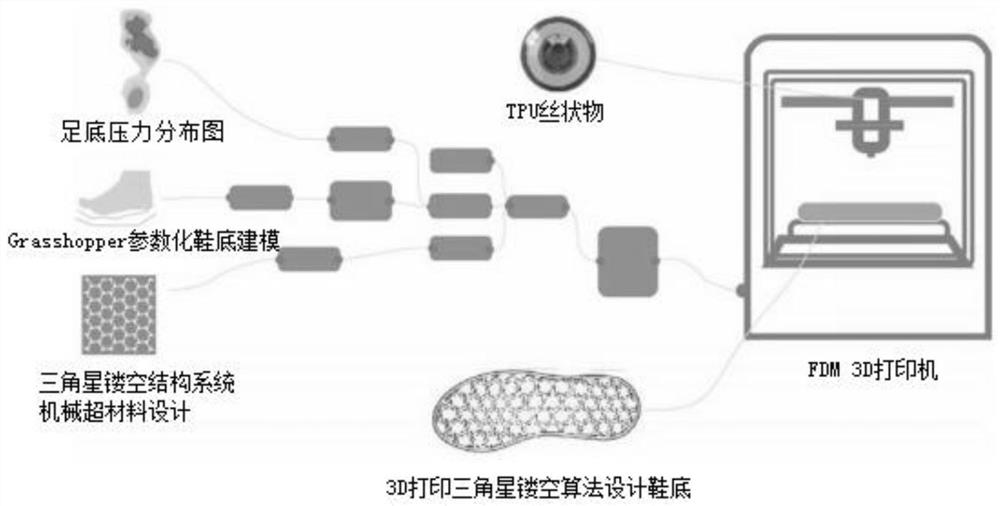

Triangular star cellular system parameterized 3D printing plantar pressure distribution sole

A honeycomb system and plantar pressure technology, applied in the field of 3D printing, can solve the problems of time-consuming, unfavorable functional soles, expensive machines, etc., and achieve the effect of alleviating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

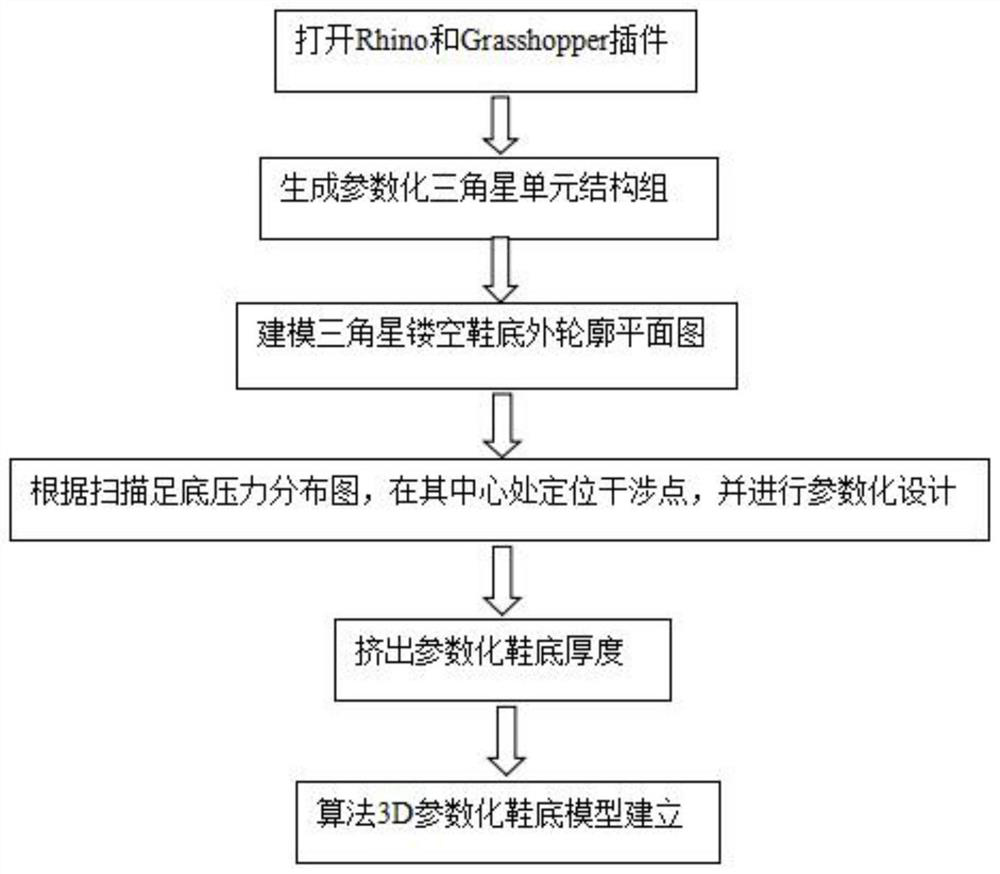

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below with reference to specific embodiments, but the embodiments of the present invention are not limited thereto.

[0044] First, the terms involved in this embodiment are explained:

[0045]Algorithms (Grosshopper algorithms): Parametric design is a design process in which the project itself is written as functions and processes, and the design process is automated by modifying the initial conditions and obtaining the project results through computer calculations. Grasshopper instructions can be opened Plugin window. Grasshopper is a graphical algorithm editor tightly integrated with Rhino's 3D modeling tools. Rhinoceros comes with its own node-based visualization language, Grasshopper, by connecting the programming method of internal battery component efficiency, building a program that follows a set of rules, allowing designers to easily change the visualization operation nodes to quickly execute parametr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com