Packaging device and manufacturing method thereof

A technology for packaging devices and plastic bodies, which is used in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., and can solve problems such as uneven thickness of electromagnetic shielding layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

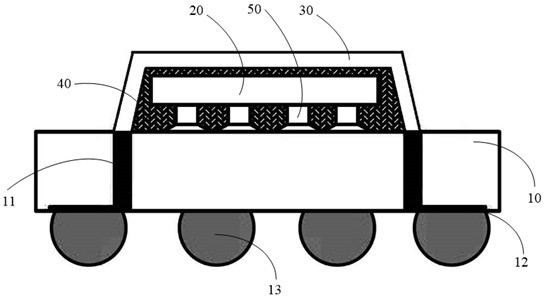

[0028] In a possible implementation method, at least one angle value corresponding to the side of the plastic seal side is greater than or equal to 40 °, and the angle value of the angle corresponding to at least one plastic seal side is less than or equal to 70 °.

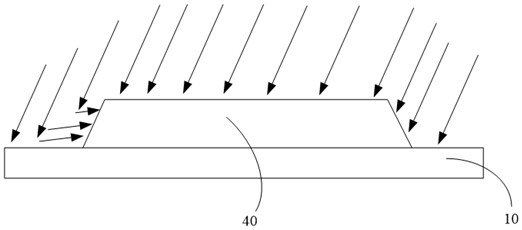

[0029] In the embodiment of this instructions, when the angle value (angle value of the sharp angle) of at least one plastic seal side is ≤70 °, the shielding layer sputtering process is performed on this parameter to obtain a more uniform shielding layer on this parameter to obtain a more uniform shielding layer.30.

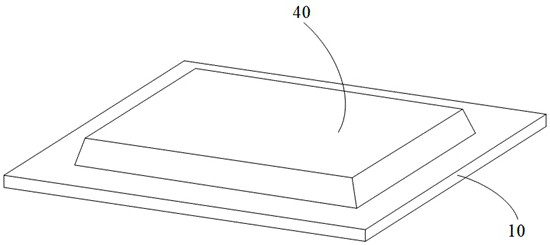

[0030] In a possible implementation method, the projection of the plastic seal 40 along the target direction is located on the first side of the substrate 10, and the target direction is perpendicular to the substrate 10.

[0031] In the embodiment of this instructions, the length of the projection area of the 40s of the plastic seal can be smaller than the length of the substrate 10, the width correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com