Method for manufacturing a transverse segment for a puller belt of a continuously variable transmission and

A technology of continuously variable transmission and transverse section, applied in belts, applications, V-belts, etc., can solve the problems of impractical, uneconomical, insufficient stiffness and/or strength of punching, and achieve the effect of increasing the overall mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

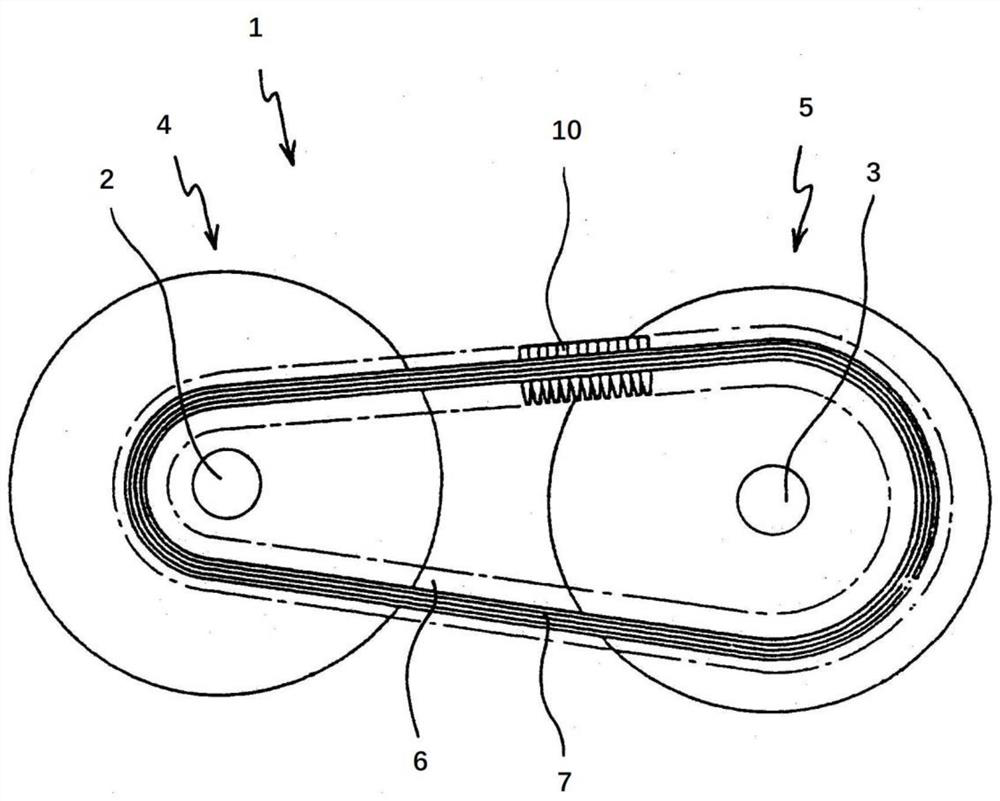

[0025] figure 1 A continuously variable transmission, for example used in a motor vehicle, is shown schematically. The continuously variable transmission is generally designated by the reference numeral 1 .

[0026] The continuously variable transmission 1 comprises two pulleys 4, 5, each of which is arranged on a corresponding pulley shaft 2, 3, respectively. The push belt 6 is arranged in a closed loop around the pulleys 4 , 5 and serves to transmit torque between the pulley shafts 2 , 3 . The pulleys 4 , 5 are each provided with two grooved pulleys, between which the respective circumferential sections of the push belt 6 are positioned and clamped so that rotation can be transmitted between the pulleys 4 , 5 .

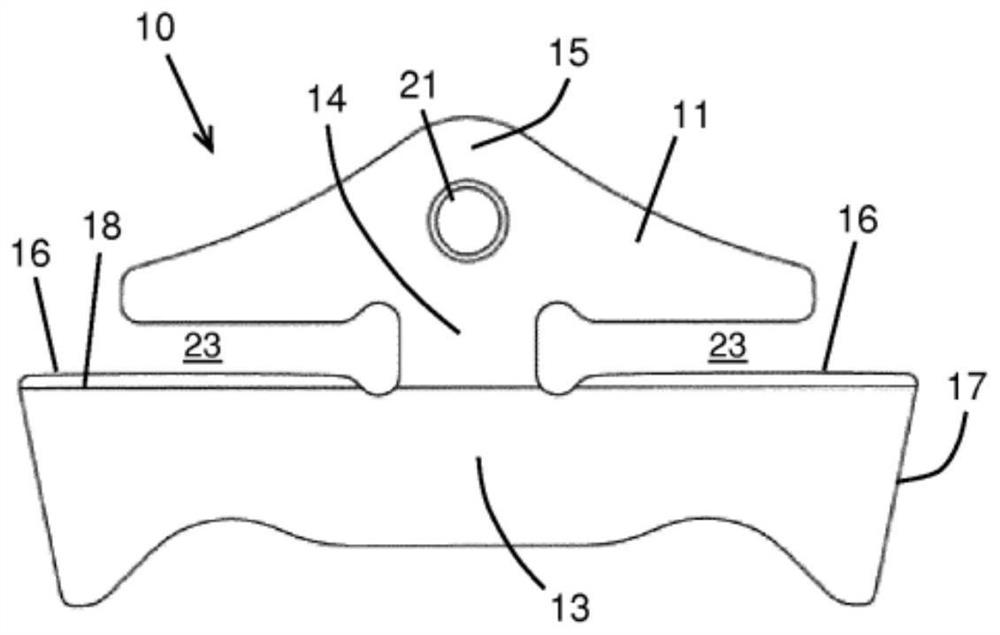

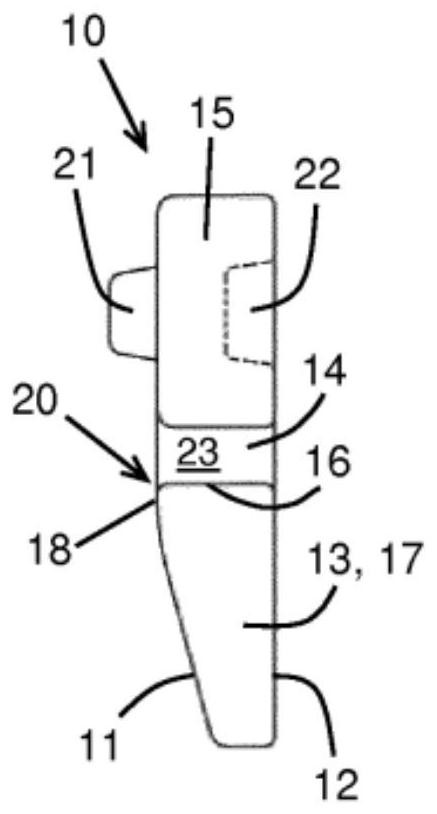

[0027] The shown push belt 6 comprises at least one loop group 7 consisting of a bundle of inter-nested continuous belts or loops. A plurality of transverse segments 10 are arranged on the ring group 7 forming a substantially continuous row along the entire circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com