Composite gasket and combined cover for large volume parenteral package

A technology of composite pad and combined cover, which is applied in transportation and packaging, packaging, packaging food, etc., can solve the problem that the hardness and elasticity of the gasket cannot be balanced, achieve the balance of hardness and elasticity, ensure normal use, and increase the hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

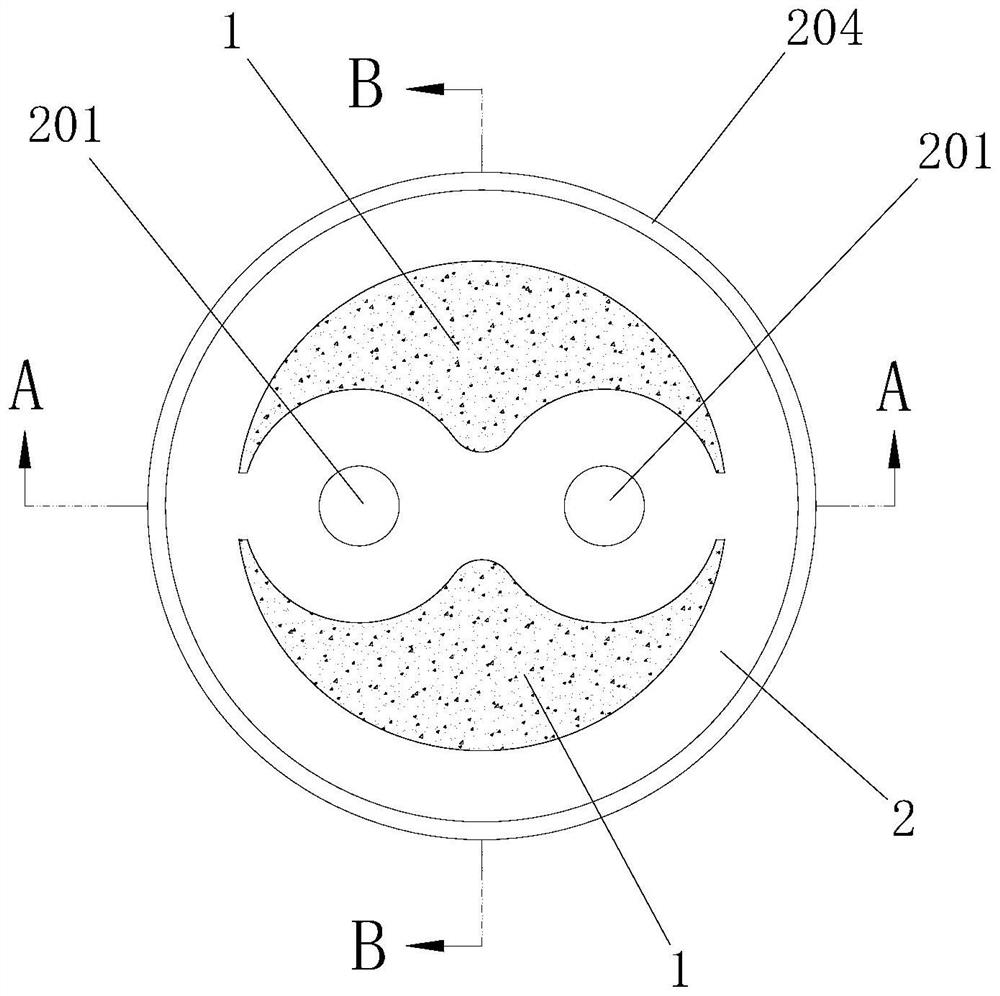

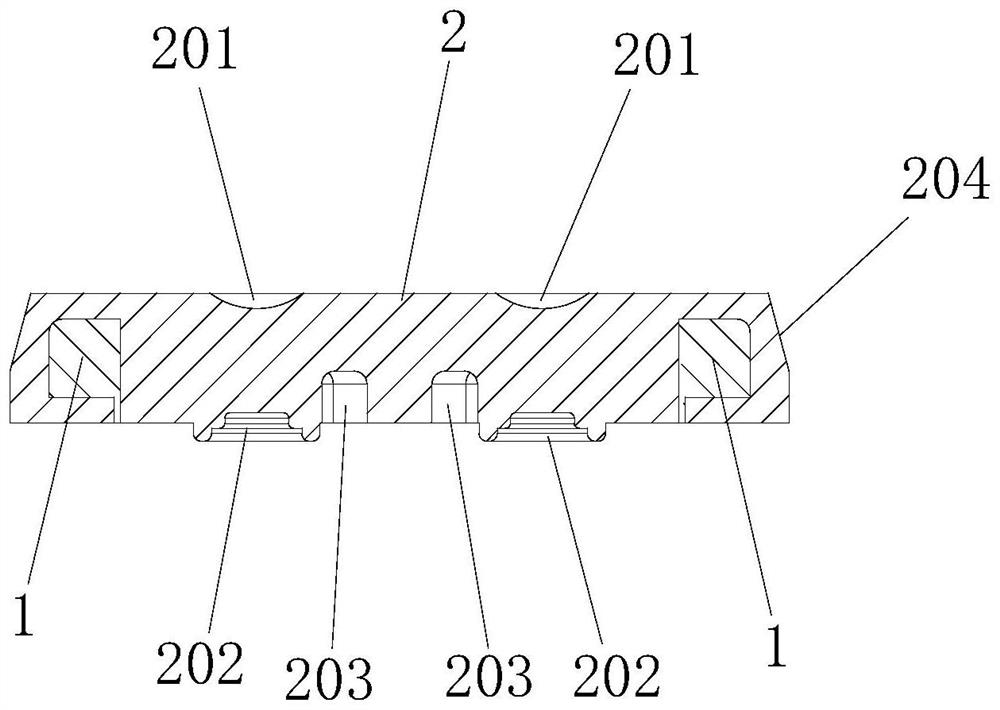

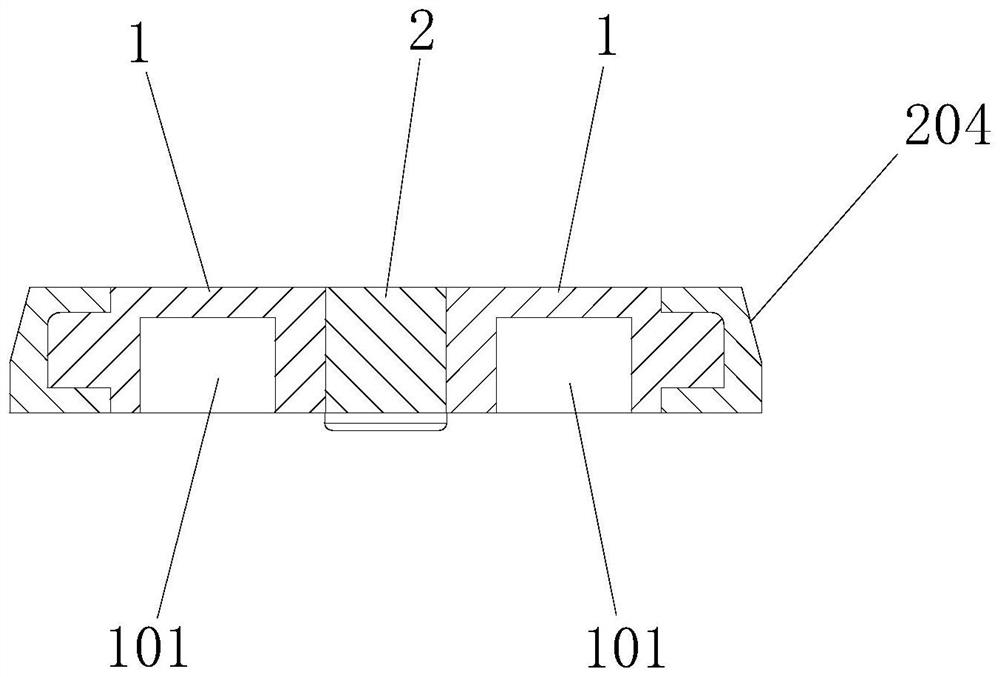

[0034] like Figure 1 to Figure 4 As shown, the present invention provides a composite gasket, the composite gasket includes an elastic body 2 and a support frame 1, the support frame 1 is used to support the elastic body 2, and a middle position of the elastic body 2 is provided for puncture At least one puncture portion 201 into which the device is inserted, and an annular sealing portion 204 is formed on the edge of the elastic body 2 along the circumferential direction of the elastic body 2. The support frame 1 is arranged inside the elastic body 2 and is located between the puncturing portion 201 and the sealing portion. The position between 204 enables the elastic body 2 to retain the original gasket in this position to hold the puncture, rebound and seal, and reduce chip falling, etc., and the part that cooperates with the cover can also achieve good contact sealing. sex.

[0035] In the present invention, a support frame 1 is added in the elastic body 2 in the shape o...

Embodiment approach 2

[0054] The present invention provides a combined cover for large infusion packaging, the combined cover for large infusion packaging includes a cover body and the above-mentioned composite gasket, the composite gasket is arranged inside the cover body, and the elastic body 2 of the composite gasket is connected to the cover. The inner wall of the body is closely attached to achieve a good sealing effect between the composite gasket and the cover body.

[0055] The production process of the combined cover for medium and large infusion packaging of the present invention is as follows: the above-mentioned composite gasket is directly injection-molded by a two-color injection molding machine, and then the composite gasket and the cover body (including the outer cover and the inner cover) are assembled together by an assembly machine, The assembly of the combined cover for the large infusion package can be completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com