Fiber slicer and slicing method

A fiber slicing and slicing technology, which is applied in the direction of instruments, scientific instruments, sampling, etc., can solve the problems of unadjustable fiber length and low production efficiency, achieve high success rate, reduce installation space, and increase the number of bundles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

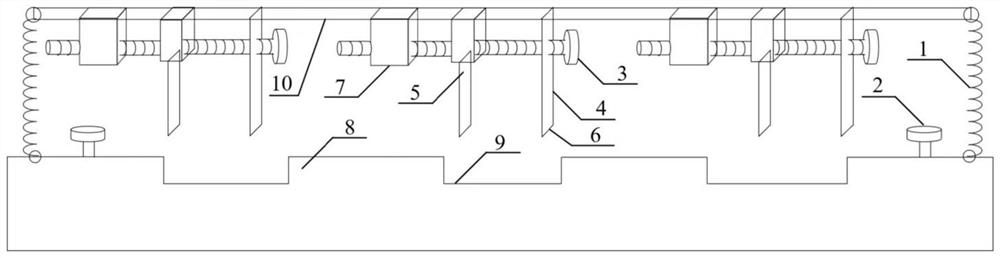

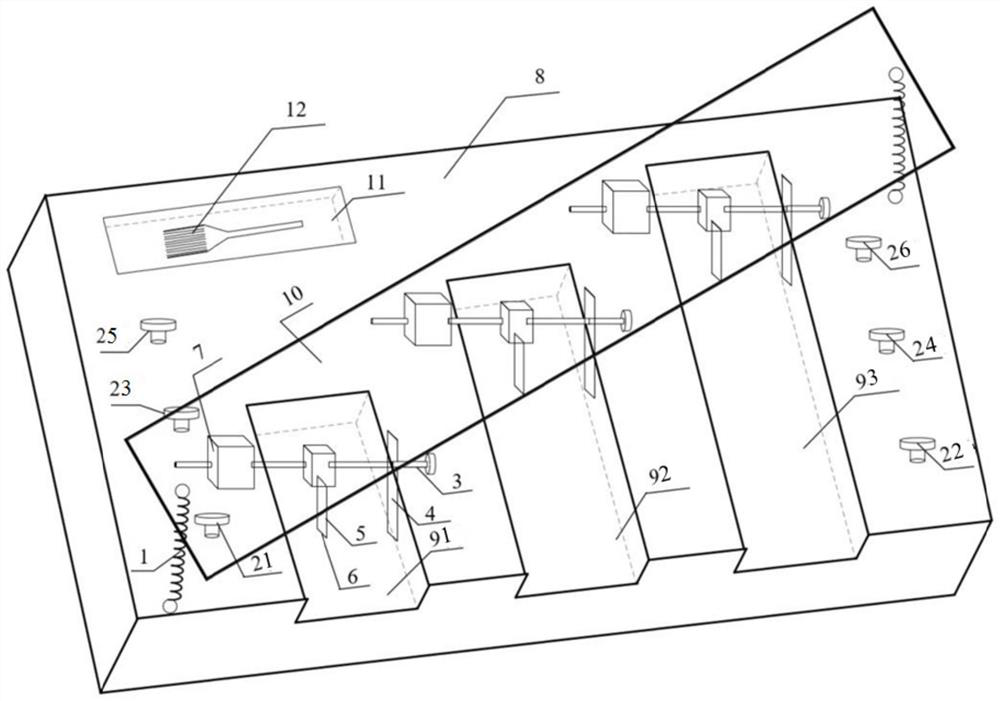

[0030] like figure 1 and figure 2 As shown, the present embodiment provides a fiber slicer, including:

[0031] The base 8 is provided with multiple groups of pulling units, and each group of pulling units is used to pull a bundle of fibers;

[0032] The mounting base 10 is erected above the base 8, and is provided with slicing units that are consistent with the number of pulling units and corresponding to them one-to-one. Each slicing unit includes two blades for transversely cutting the corresponding fibers. A ball screw 3 is arranged between the blades, and the distance between the two blades is adjusted by screwing it;

[0033] The elastic body is arranged between the base 8 and the mounting seat 10 and supports the mounting seat 10 with a downward pressing space.

[0034] The multiple sets of pulling units provided can pull multiple bundles of fibers to be cut, and a matching slicing unit is set to realize cross-cutting of different fibers to be cut by pressing, so th...

Embodiment 2

[0046] The present embodiment provides a slicing method according to the fiber slicer in Embodiment 1, comprising the following steps:

[0047] Multiple groups of pulling units are used to pull a bundle of fibers group by group, that is, the first screw 21 and the second screw 22 are used to pull a bundle, the third screw 23 and the fourth screw 24 are used to pull a bundle, and the fifth screw 25 and the first screw 25 are used to pull a bundle of fibers. The six screws 26 pull a bundle so that the three bundles of fibers are in the same horizontal plane and parallel to each other. Adjust the distance between the two blades on each slicing unit according to the required fiber length, press the mounting seat 10 and the spring 1 between the base 8 and the two blades to cross-cut the corresponding fibers. After the slicing is completed, under the rebound effect of the elastic body, The mount 10 returns to the original position. After the fiber is cross-cut, the cross-cut cut ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com