Building energy-saving construction conveying device based on mechanical transmission

A technology of building energy saving and mechanical transmission, applied in the direction of conveyors, cleaning devices, conveyor objects, etc., can solve the problems of inconvenience, dust flying, etc., and achieve the effect of speeding up the drying process, spraying the area comprehensively, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

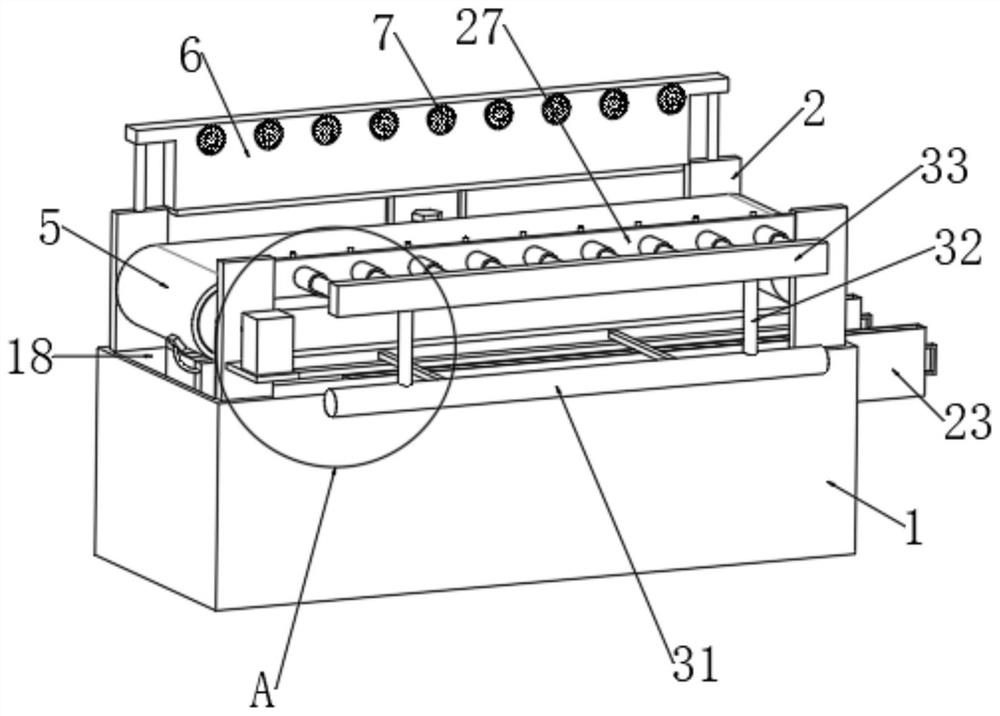

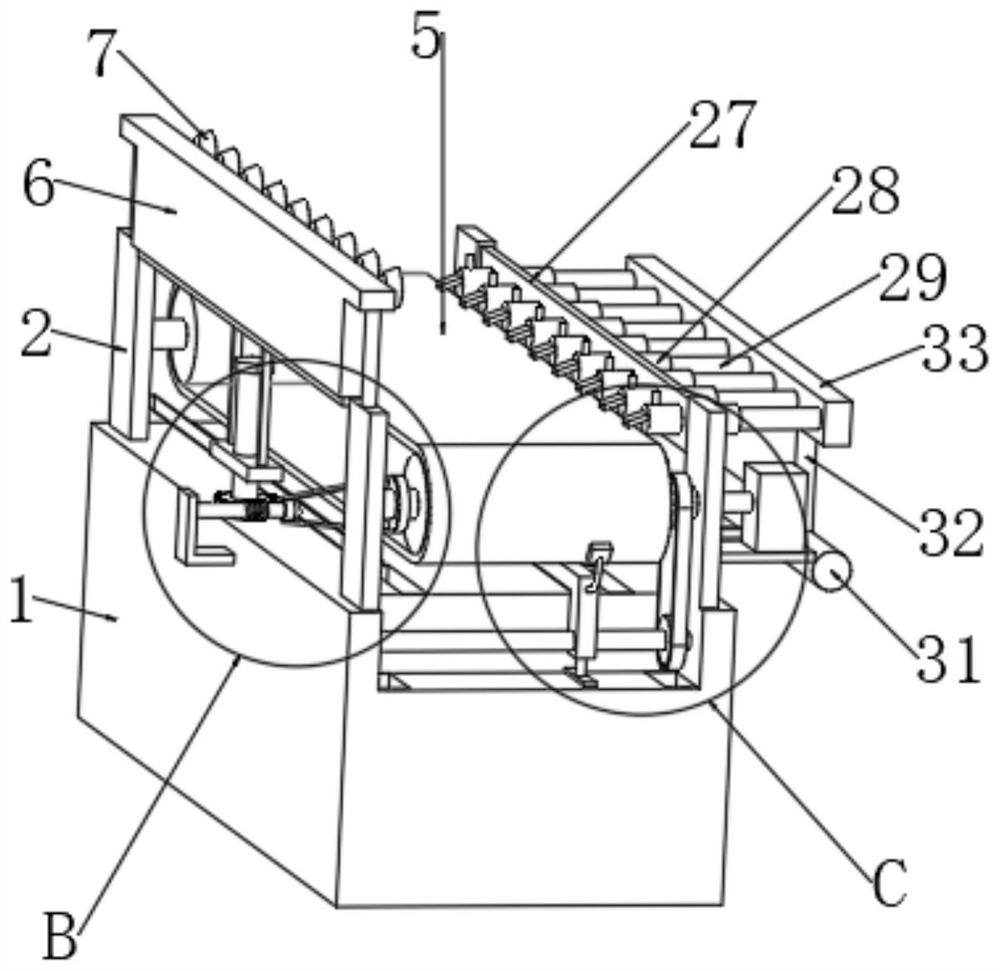

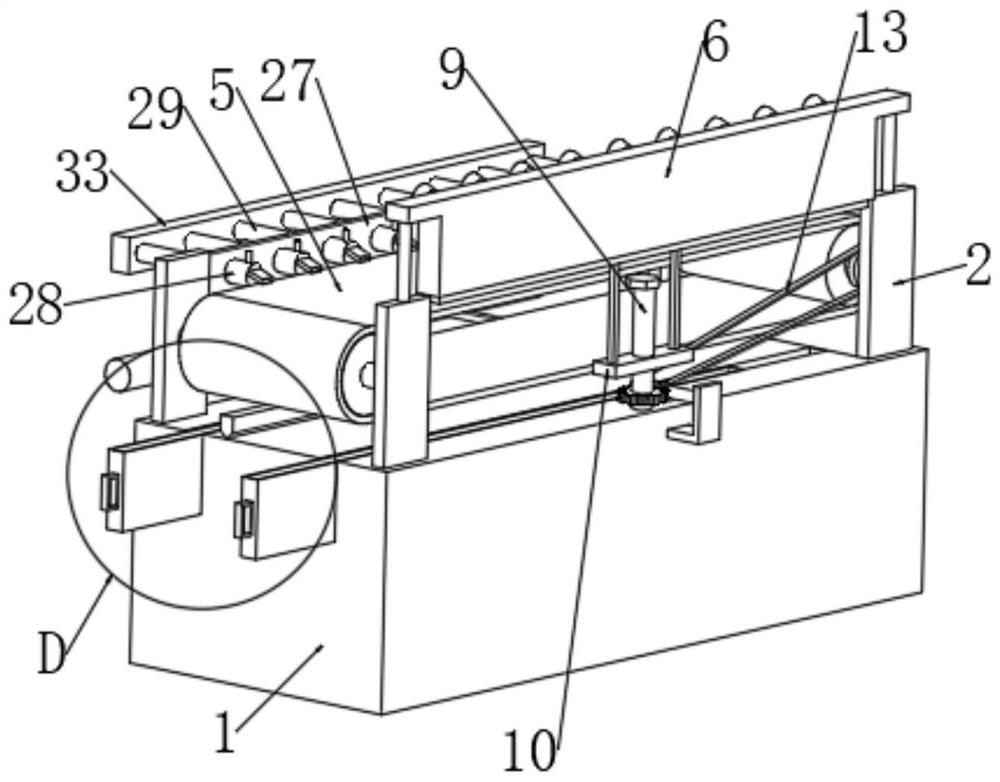

[0030] refer to Figure 1-7 , A building energy-saving construction conveying device based on mechanical transmission, comprising a platform body 1, two pairs of support plates 2 are fixedly installed on the upper surface of the platform body 1, a rotating shaft 3 is rotatably installed between the two pairs of support plates 2, and the rotating shaft 3 is fixed on the A rotating roller 4 is sleeved, and a conveyor belt 5 is wound on the two rotating rollers 4. A servo motor 21 is fixedly installed on the side wall of one of the support plates 2, and the output shaft of the servo motor 21 is fixedly connected to one end of one of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com