Feeding structure of solid waste treatment machine and solid waste treatment machine

A processor and feeding technology, applied in the direction of solid waste removal, conveyor objects, loading/unloading, etc., can solve problems such as clogging the feeding pipeline, and achieve the effect of maintaining smoothness, improving adaptability, and reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

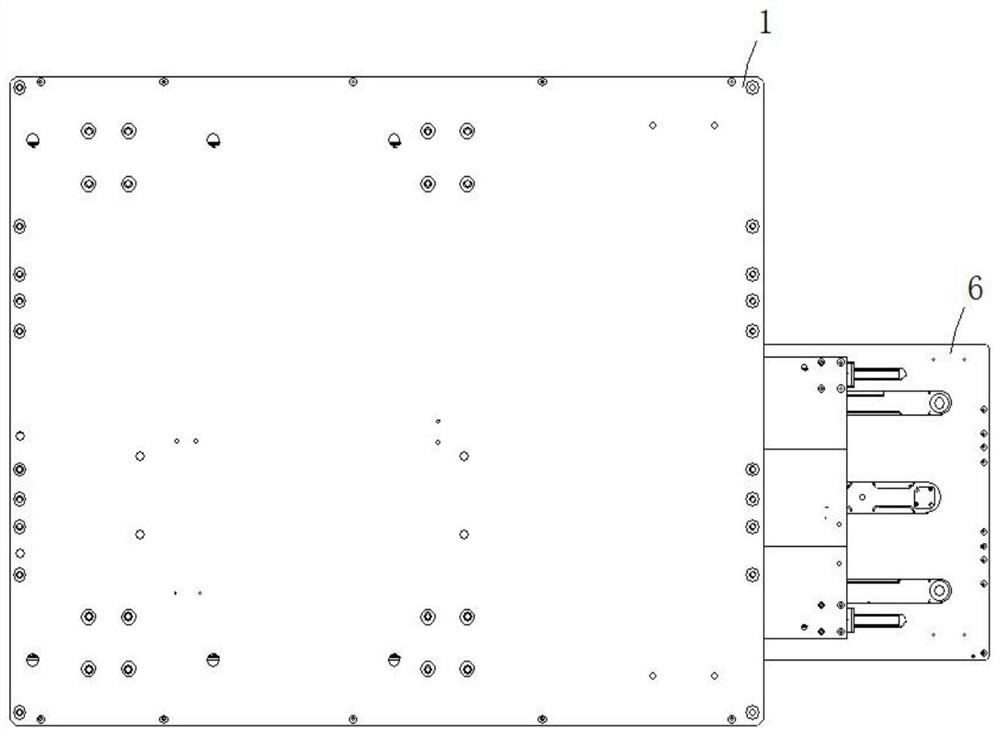

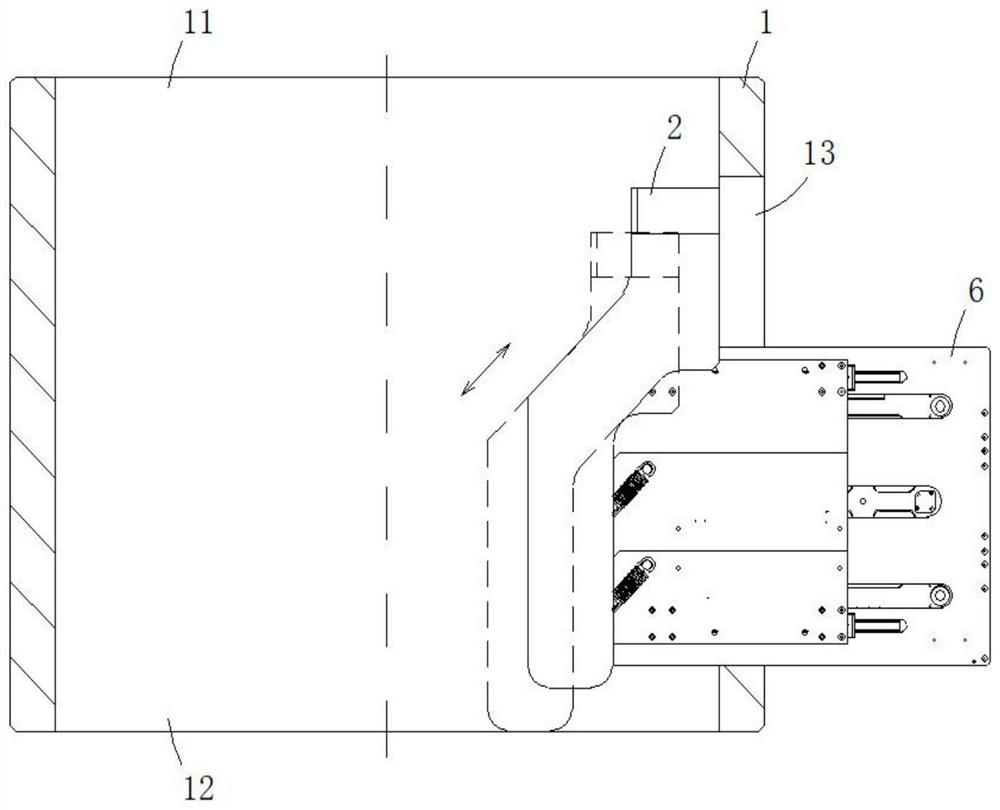

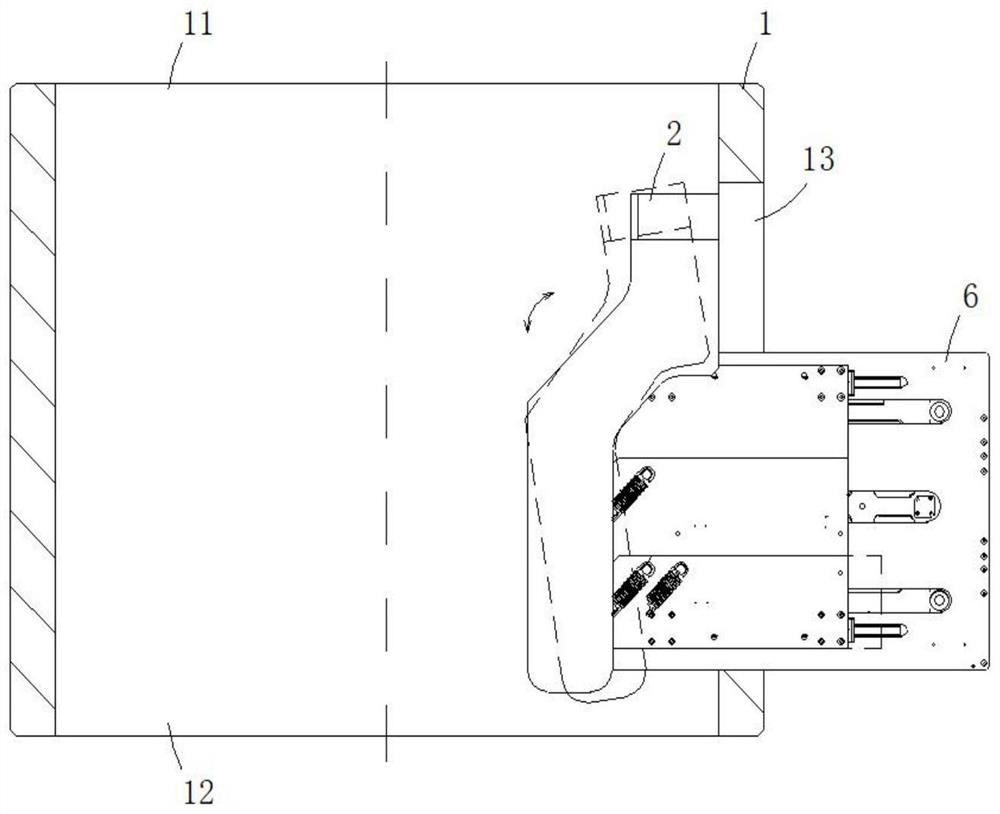

[0028] like Figure 1 to Figure 6 As shown, the feeding structure of the solid waste treatment machine according to the embodiment of the present invention includes a feeding channel 1, a baffle 2, an elastic member 3, a slider, a driving cylinder, and a base 6, which can be on one side of the feeding channel 1. A through hole 13 is formed by means including but not limited to turning, the base 6 can be fixedly installed in the through hole 13 by means including but not limited to bolt connection, the baffle 2 is installed inside the feed channel 1, and the feed channel 1 It includes a feed port 11 and a discharge port 12 , the feed port 11 is connected to the discharge port 12 , the feed port 11 is located at the top of the feed channel 1 , and the discharge port 12 is located at the bottom end of the feed channel 1 . It is easy to understand that the solid waste enters from the feed port 11 and falls from the discharge port 12 under the action of gravity.

[0029] The slide...

Embodiment 2

[0036] like Figure 1 to Figure 6 As shown, in the feeding structure of the solid waste treatment machine according to the embodiment of the present invention, in order to solve the problem of how to maintain the support baffle 2 in the whole process more stably, the slider includes a support slider 4, and the support slider 4 is located on the top of the base 6 For installation, the support slider 4 is connected to the top of the baffle plate 2 , and the support slider 4 is connected to a driving oil cylinder 41 . It is easy to understand that a chute 61 can be formed on the base 6 to guide the support slider 4 by means including but not limited to turning. Correspondingly, the telescopic direction of the driving cylinder 41 and the extension direction of the chute 61 are the same.

[0037] In order to solve the problem of how to adjust the posture of the baffle 2 more flexibly, the slider includes an auxiliary slider 5, which is installed at the bottom of the base 6, the auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com