Lifting hanging basket device for non-vertical building

A non-vertical technology for construction, applied in the field of hanging baskets, can solve the problems of inability to use buildings, weak auxiliary effect of lifting and lowering hanging baskets, low safety, etc., and achieve the effects of improving efficiency, compact internal structure, and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

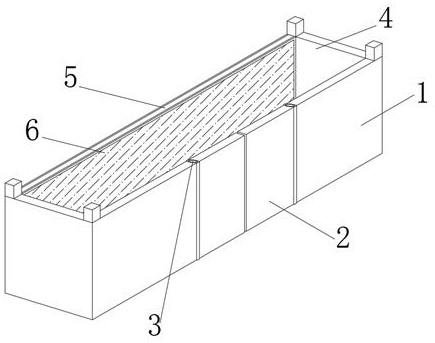

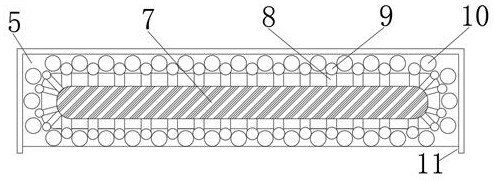

[0022] like Figure 1-Figure 4 As shown, the present invention provides a non-vertical building lifting and hanging basket device, comprising a front baffle 1, a closing plate 2 is installed in the middle of the front baffle 1, and living hinges 3 are fixedly installed at the left and right ends of the closing plate 2 , the living hinge 3 is fixedly connected with the closing plate 2, the living hinge 3 is located on the inner side of the front baffle 1, the rear ends of the left and right ends of the front baffle 1 are fixedly installed with a fixed plate 4, and the rear end of the fixed plate 4 is fixedly installed with a flexible plate 5 , the front end of the flexible board 5 is fixedly provided with a rubber stretching layer 6 .

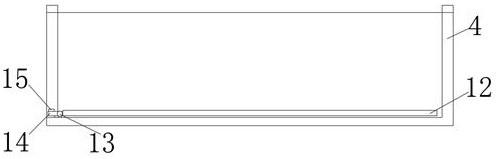

[0023] Manually push and pull the closing plate 2 to realize the switch closing plate 2, which is the guardrail door for the staff to get on the machine and for protection, and then the construction personnel can move to the pedal 12 inside the ...

Embodiment 2

[0030] The same parts of this embodiment and Embodiment 1 will not be repeated here, and the parts of this embodiment that are different from Embodiment 1 are: Figure 4 As shown, a connecting buckle 16 is fixedly installed at the rear end of the lower end of the flexible board 5, the connecting buckle 16 is fixedly connected with the rear end of the flexible board 5, and a winding rod 17 is fixedly installed on the inner side of the connecting buckle 16, and the connecting buckle 16 is connected and hoisted. The steel cable is then wound around the winding rod 17 for a week. At this time, the steel cable can be used to pull the gondola to ascend or descend. Using the steel cable to lift and lower the gondola as a whole is the basic work, which can ensure that the gondola can be stably carried at high altitudes. Or low-level renovation work.

Embodiment 3

[0032] The same parts of this embodiment and the first embodiment will not be repeated, and the parts of this embodiment and the first embodiment are different in that: in this embodiment, as Figure 4 As shown, a telescopic rod 18 is fixedly installed above the connecting buckle 16, a connecting seat 19 is fixedly installed on the outer side of the left end of the telescopic rod 18, and the telescopic rod 18 is fixedly connected with the rear end of the flexible board 5. By installing the connecting seat 19 on the outside of the gondola , so that the hanging basket can be stably connected to the guide rail, and the telescopic rod 18 with variable length is a component that can perform telescopic operation and change the length of the body, and the telescopic rod with variable length is used to adjust the distance between the hanging basket and the irregular wall The distance can effectively improve the construction efficiency of the construction personnel, and the connection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com