GTF engine gearbox with adjustable supporting rigidity

A technology for supporting rigidity and engine, applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc., which can solve the problem of low assembly precision, high difficulty and uneven force of splines in segmented herringbone ring gear and other problems, to achieve uniform load distribution, increase elasticity, and solve the effect of uneven force on splines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

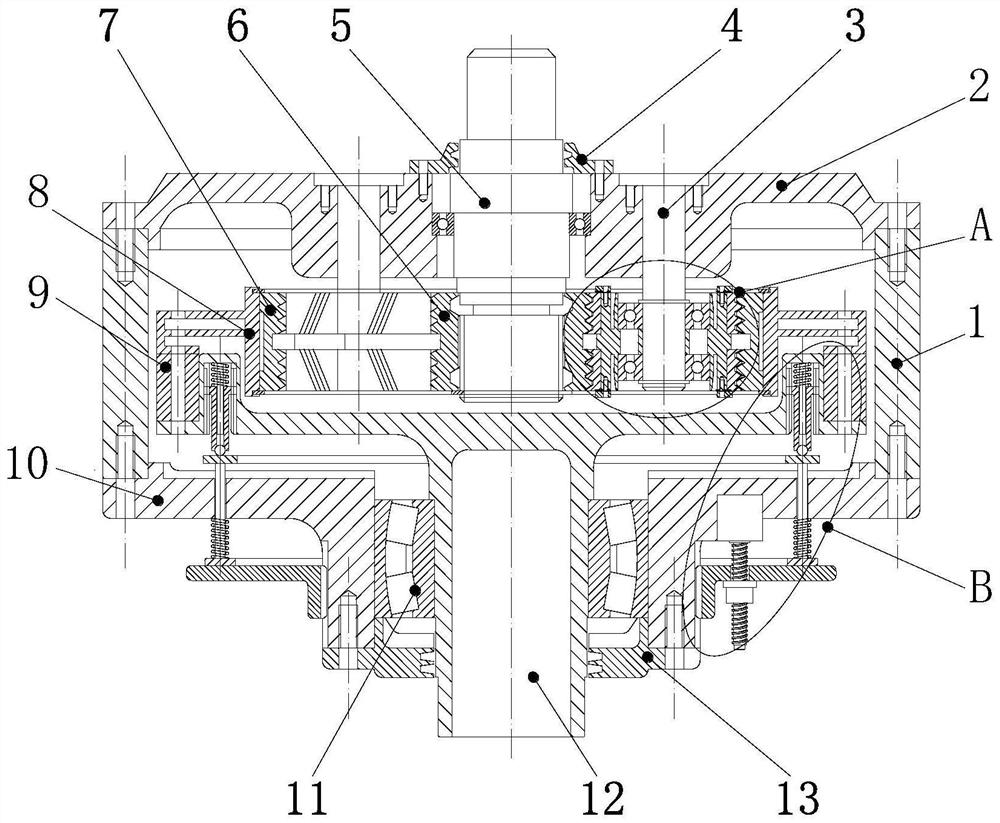

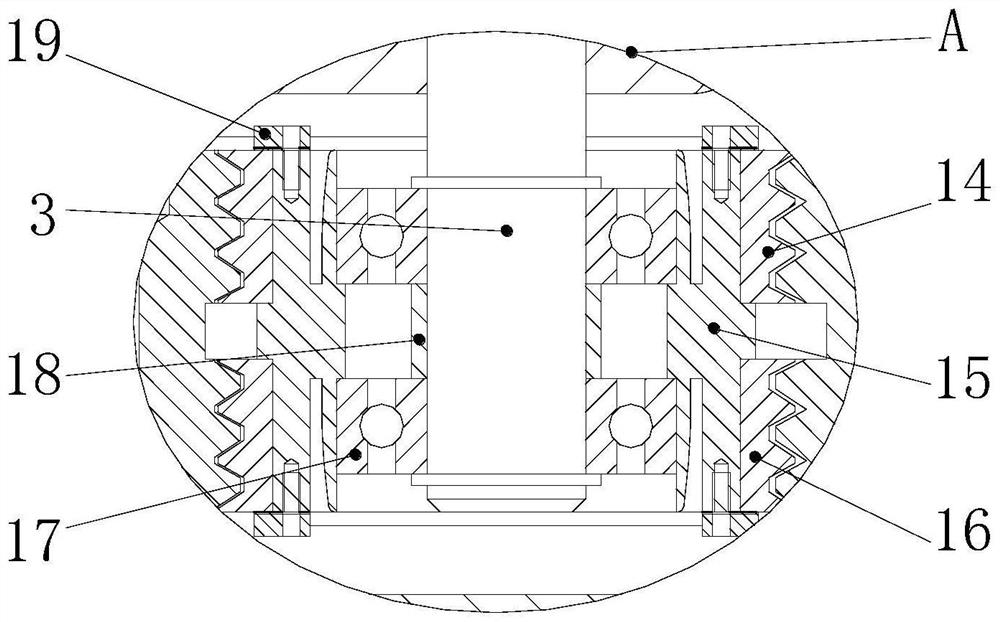

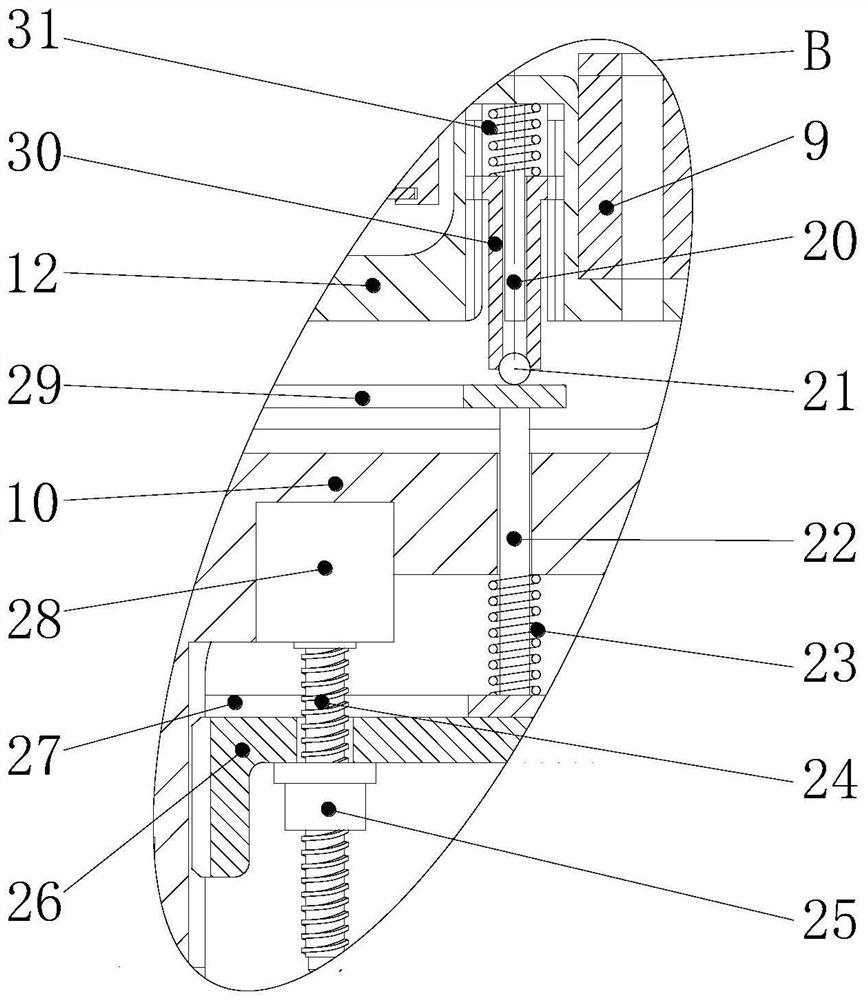

[0043] refer to Figure 1-8 , the present invention is a GTF engine gearbox with adjustable support stiffness, including a box body 1, the box body 1 and the upper box cover 2 are generally fixed by screws, the input shaft 5 penetrates the upper box cover 2, and is connected with the upper box cover 2. They are rotatably connected by deep groove ball bearings. The outer surface of the port of the upper box cover 2 is fixedly connected with the input shaft end cover 4 by screws. The input shaft end cover 4 is sleeved on the input shaft 5 to position the input shaft 5. The inner end surface of 2 is provided with a plurality of star wheel shafts 3 evenly running through the circumferential direction. The star wheel shaft 3 is fixedly connected with the upper case cover 2 by screws. The lower end of each star wheel shaft 3 is provided with a first star wheel 14 and a second star wheel 14. The star wheel 16 , the first star wheel 14 , the second star wheel 16 and the star wheel sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com