An environmentally friendly assembled wall pressing machine

A technology for pressing machines and walls, which is used in manufacturing tools, ceramic molding machines, building maintenance, etc., can solve problems such as uneven stress, increased transportation costs, and reduced production costs, and achieves reduced cracking, compact structure, and reduced cracks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

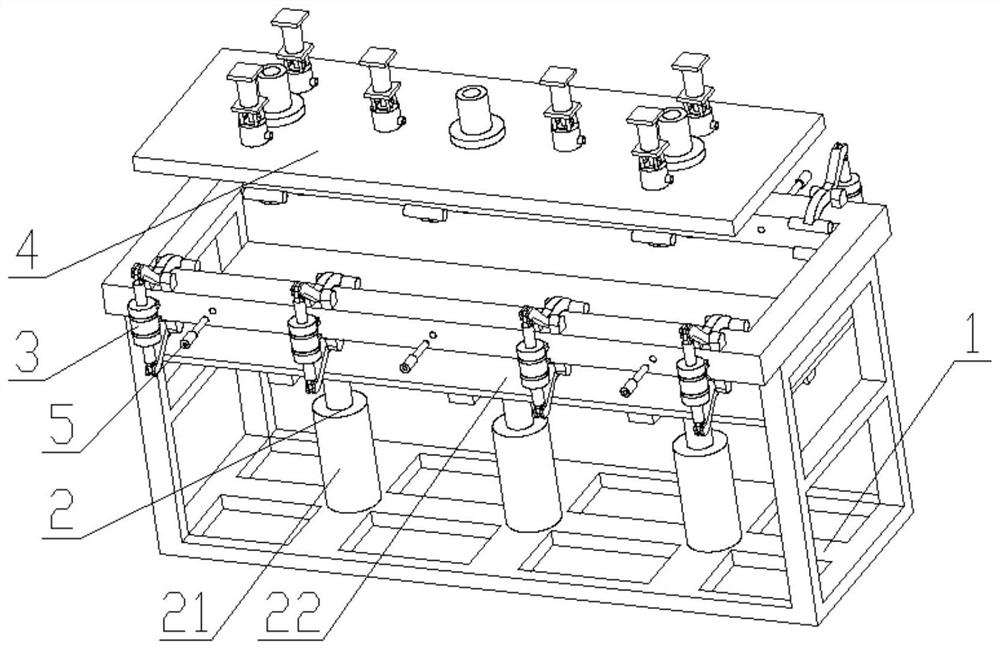

[0028] Such as Figure 1 to Figure 6 Shown; A kind of environment-friendly assembling wall pressing machine includes support 1, shaping frame 11, upper pressing mechanism 2, lower pressing mechanism 4 and several shaping insert rods 5, and described shaping frame 11 and upper pressing mechanism 2 are arranged on On the support 1, the pressing mechanism 4 is arranged above the shaping frame 11, and the shaping frame 11 is located between the pressing mechanism 4 and the pressing mechanism 2, and the compression parts in the pressing mechanism 4 and the pressing mechanism 2 All cooperate with the shaping frame 11; the shaping frame 11 is provided with several sockets 12, and one end of the shaping insertion rod 5 passes through the socket 12 and extends into the shaping frame 11, and the shaping frame 11 is provided with several Auxiliary crimping mechanism 3, the crimping part of described auxiliary crimping mechanism 3 cooperates with the compression position in downpressing m...

Embodiment 2

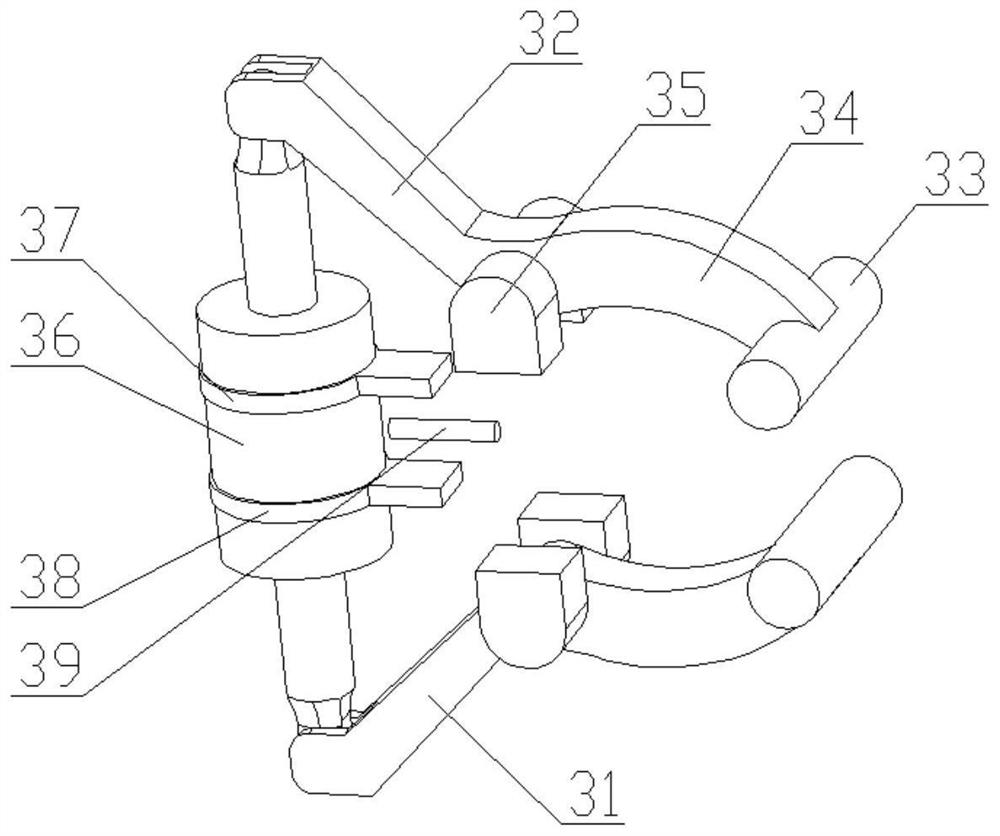

[0031] On the basis of Embodiment 1, the auxiliary crimping mechanism 3 includes a lower auxiliary mechanism 31, an upper auxiliary mechanism 32 and a two-way oil cylinder 36, and the lower auxiliary mechanism 31 and the upper auxiliary mechanism 32 are symmetrically fixed on the upper and lower sides of the shaping frame 11. side, the power input ends of the lower auxiliary mechanism 31 and the upper auxiliary mechanism 32 are respectively movably connected with the two-way oil cylinder 36, and the pressing ends of the lower auxiliary mechanism 31 and the upper auxiliary mechanism 32 are connected with the corresponding pressing plate 41 and the upper pressing plate 22 respectively. Cooperate with each other; the two-way oil cylinder 36 is provided with an upper limit block 37 and a lower limit block 38, and a limit rod 39 is arranged between the upper limit block 37 and the lower limit block 38, and the limit rod 39 is fixed on the shaping frame 11 above; the lower auxiliary ...

Embodiment 3

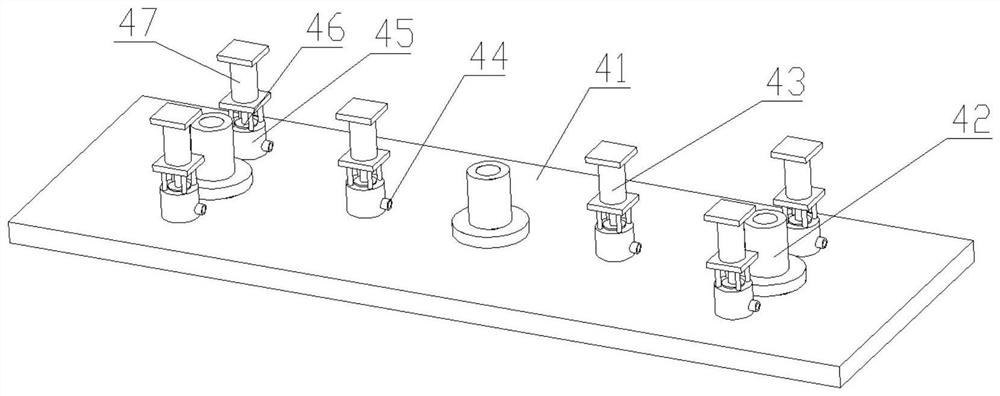

[0034] On the basis of Embodiment 2, at least two pouring ports 44 are provided on one side of the pouring pipe 45; the V-shaped crowbar 34 includes a power bar 341 and a pressure bar 342, and the pressure bar 342 is semicircular. The diameter of the semicircle is the width of the frame of the sizing frame 11 plus 1 / 2 the width of the pressing rod 33; Connect the shaped column 53; the shaped column 53 is tapered, and the outside of the shaped column 53 forms an angle A with the axis of the shaped column 53, and the degree of the angle A is 0.5 degrees to 3.0 degrees; the pouring cylinder 47 and the pouring pipe 45 is provided with a connecting column; the length of the power rod 341 is at least 2 times longer than the diameter of the semicircular pressure rod 342 .

[0035] By setting at least two pouring ports 44, a variety of grouts can be switched and introduced to facilitate concrete pouring. The pressure bar 342 in the V-shaped crowbar 34 is set in a semicircle, so that w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com