Efficient multi-stage heating furnace burner

A heating furnace and burner technology, which is applied in the directions of burners, gas fuel burners, combustion types, etc., can solve the problems of inability to improve the thermal efficiency of the heating furnace, inability to adapt to various working conditions, and inappropriate requirements of the burner, to ensure Combustion flame stability, wide application range, combustion flame stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

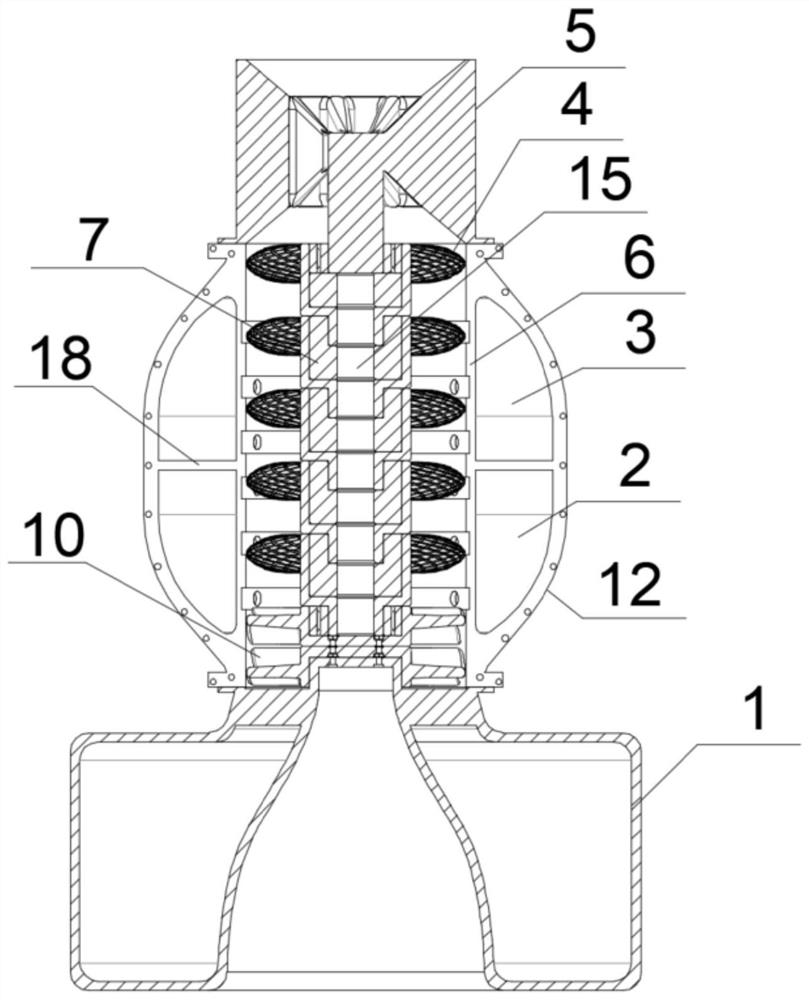

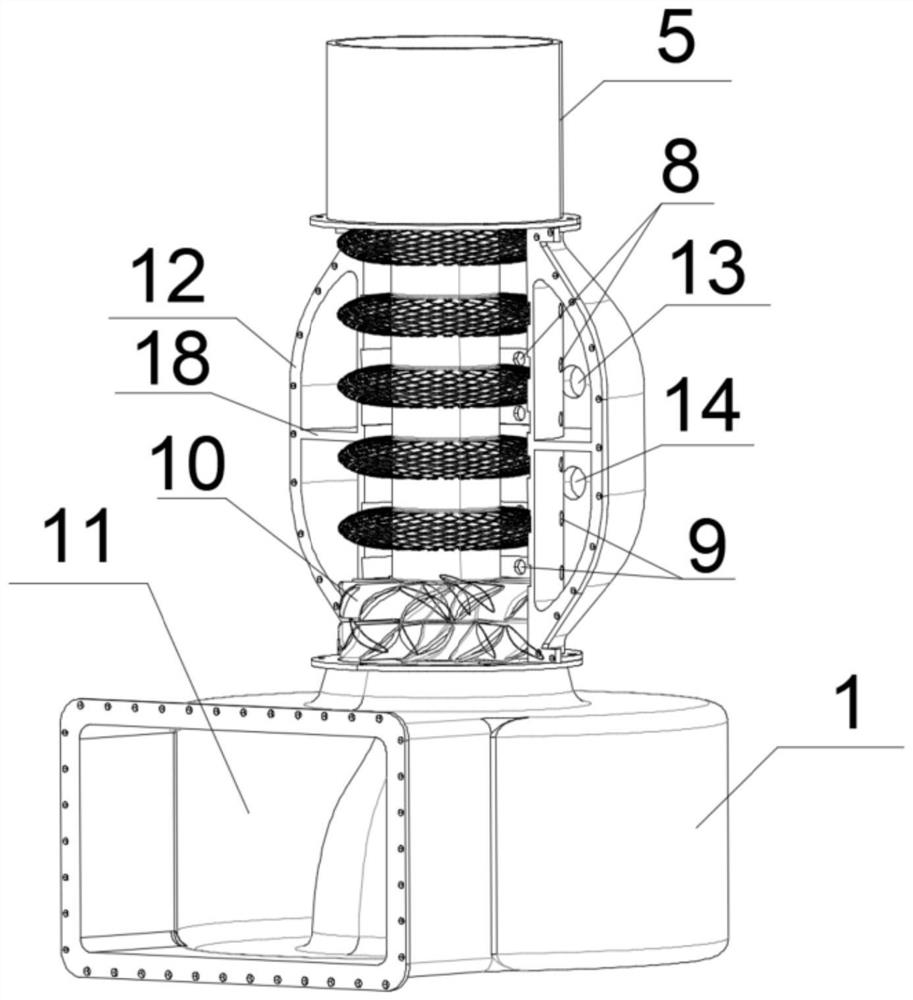

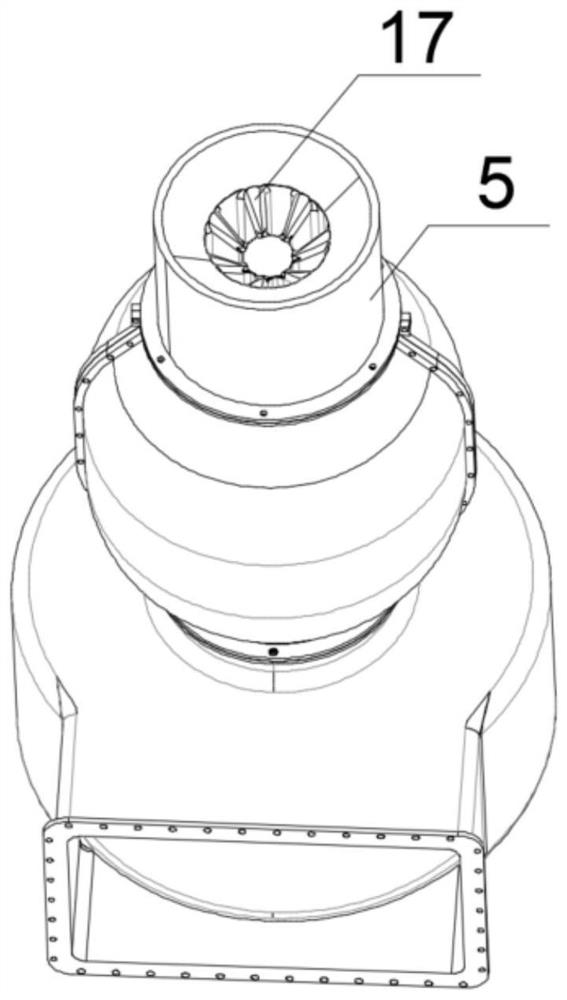

[0029] A high-efficiency multi-stage heating furnace burner, such as Figure 1-4 As shown, it includes a casing 12, an air outlet 5 is connected above the casing 12, a base 1 is connected below the casing 12, a pipe 6 is arranged inside the casing 12, and a pipe 6 is arranged between the casing 12 and the pipe 6. In the first chamber 2 and the second chamber 3, a plurality of interconnected connecting shafts 15 are arranged in the pipeline 6, and each connecting shaft 15 is covered with a detachable shaft sleeve 7, and the detachable shaft sleeve 7 is externally fixed A rotating sphere 4 is connected; a wind guide wheel 10 is also arranged in the pipe 6 , and the wind guide wheel 10 is connected with one of the connecting shafts 15 .

[0030] like figure 1 As shown in or 2, the first chamber 2 and the second chamber 3 are separated by a partition 18 to prevent the gas between the first chamber 2 and the second chamber 3 from flowing with each other.

[0031] like figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com