Friction stir welding tool fracture failure detection device and method

A technology of friction stir welding and stirring tools, which is applied in the direction of measuring devices, manufacturing tools, welding equipment, etc., can solve the problems of scrapped processed products, prone to fracture and failure, and the production rhythm cannot meet the processing rhythm requirements of large batches of products, etc., to achieve accurate The effect of improving the rate and reducing the possibility of detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

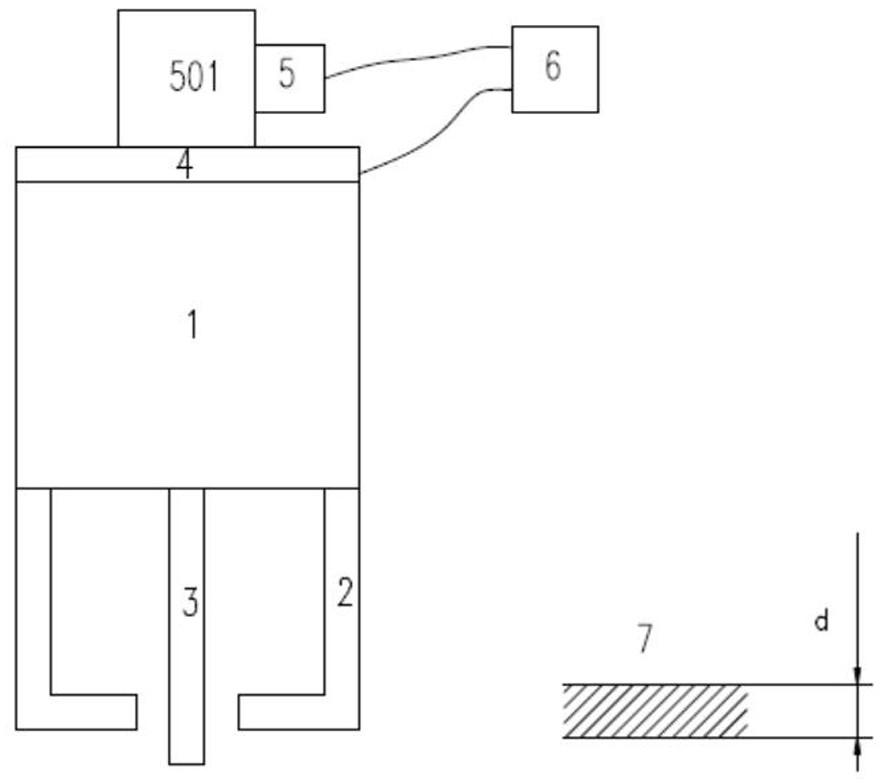

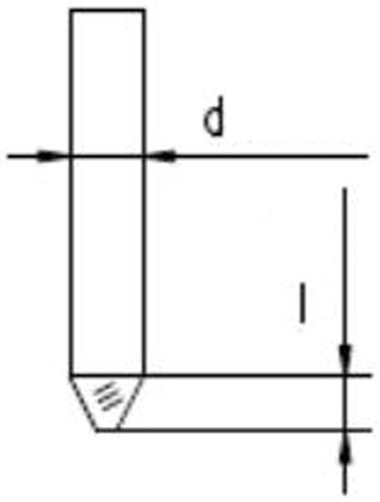

[0027] The detection device for the fracture and failure of the friction stir welding tool of the present invention includes a handpiece 1, a main shaft connected to a motor 501 is arranged in the handpiece 1, a fixed stationary shoulder 2 is arranged on the handpiece 1, and a stirring shaft is arranged on the main shaft. The tool 3, the stirring tool 3 is protruded from the through hole on the stationary shaft shoulder 2, and is characterized in that: a pressure sensor 4 and a torque sensor 5 are arranged between the main shaft and the motor 501, the pressure sensor 4 and the torque sensor 5 and a detection module 6 connected.

[0028] The handpiece 1 can be in the form of an electric spindle in which the drive of the motor 501 and the drive of the main shaft are integrated together, or the form of a mechanical spindle in which the drive of the motor 501 and the drive of the main shaft are separated.

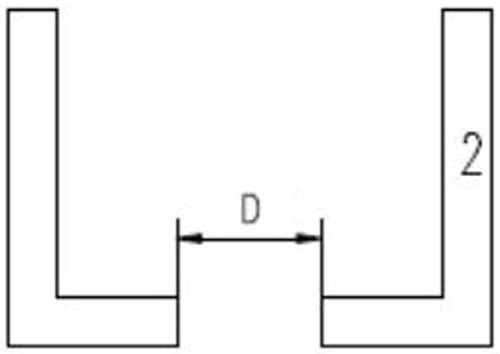

[0029] The stationary shaft shoulder 2 is bowl-shaped and has a through ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap