Electric vehicle chassis scratch three-dimensional detection method based on deep learning

A technology of deep learning and electric vehicles, applied in electric vehicles, neural learning methods, 3D object recognition, etc., can solve problems such as the unevenness of the automobile chassis, the inability to detect in real time, and the slow processing speed of point clouds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

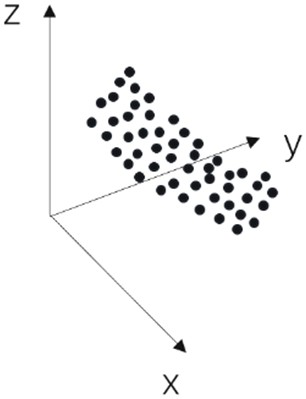

[0033] Embodiment: a three-dimensional detection method for scratches on an electric vehicle chassis based on deep learning, the method includes the following steps. In step S1, an RGB-D camera is used to collect a picture of the vehicle chassis.

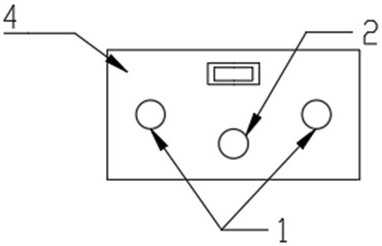

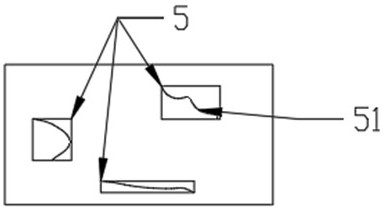

[0034] like figure 1 As shown, the RGB-D camera used in step S1 includes a housing 4, a left IR camera 1, a right IR camera and an RGB camera 2, the RGB camera is located in the center of the housing, the left IR camera and the The right IR camera is symmetrical about the RGB camera. A MEMS micro-mirror projector (MEMS optomechanical) is fixedly installed above the RGB camera. The RGB-D camera includes an RGB camera and an IR camera. When in use, it can be directly Use the RGB camera to capture the plan, and at the same time: three cameras take pictures of the checkerboard calibration board at different positions, calibrate the camera's internal and external parameters by Zhang Zhengyou's method, and then calculate the rotation tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com