Aluminum-wood combining mechanism for building and using method thereof

An aluminum-wood technology for construction, which is applied in the field of aluminum-wood combination mechanisms for construction, can solve the problems that the connection position of aluminum-wood cannot be tightly connected, the connection position is prone to wrong platform, mold expansion, and the size of the profile structure is inconsistent, etc., to achieve lifting connection Stability, improve connection stability, the effect of smooth connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

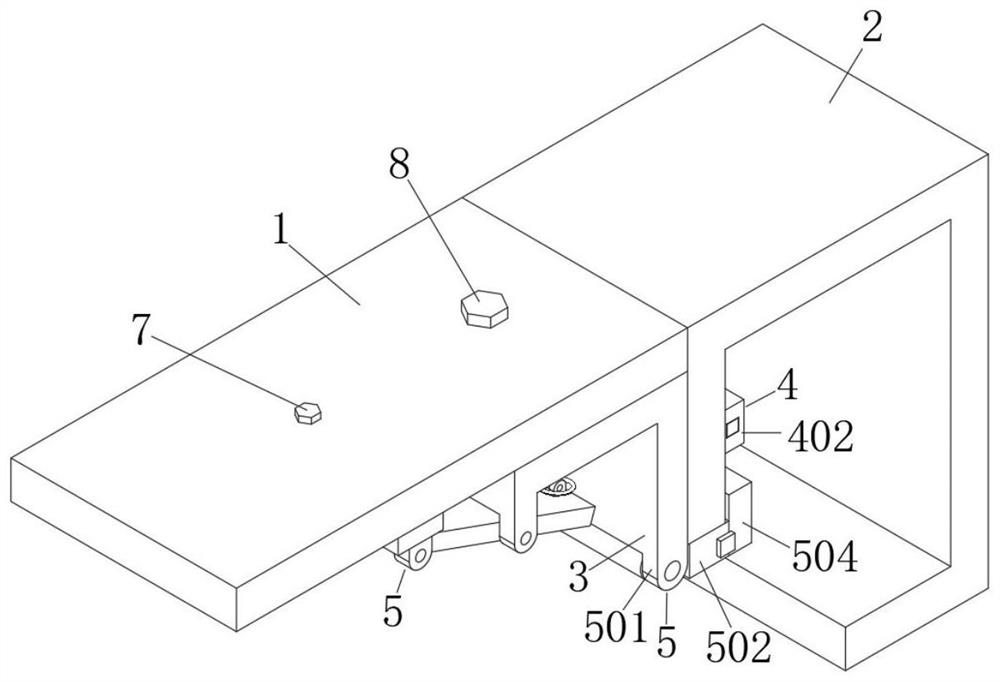

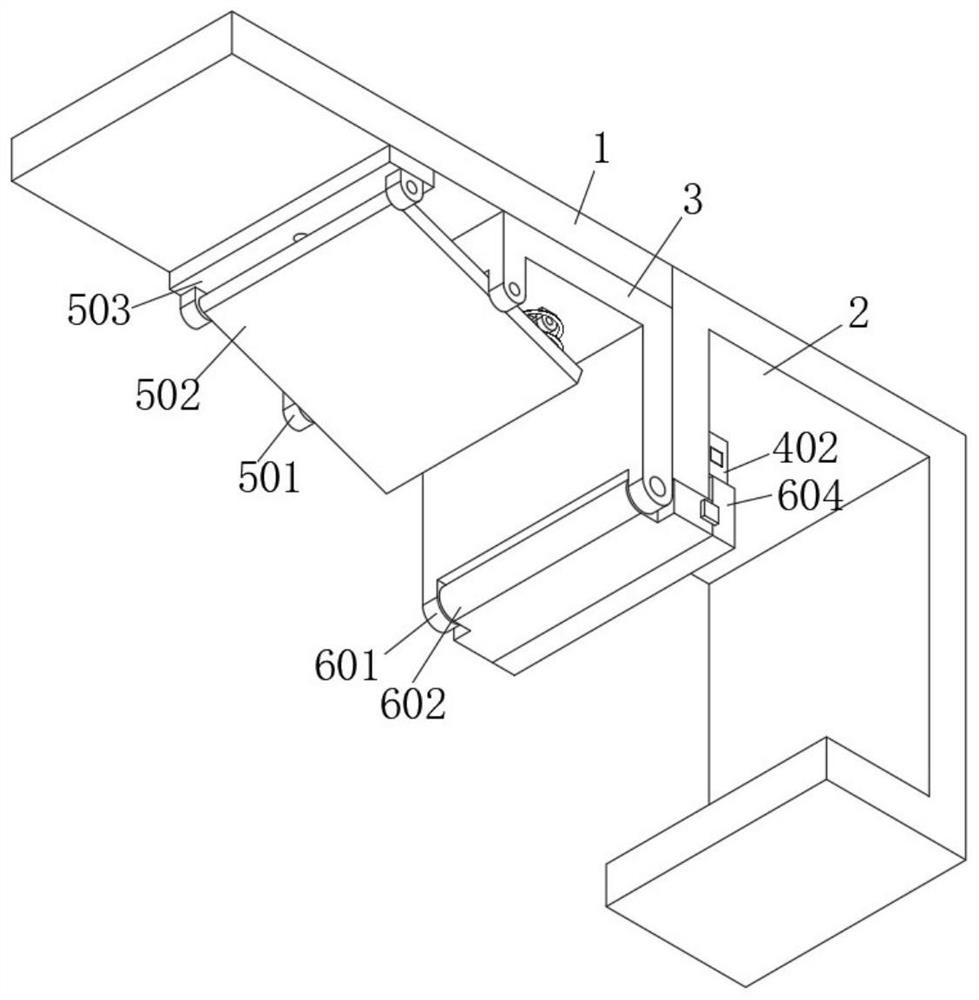

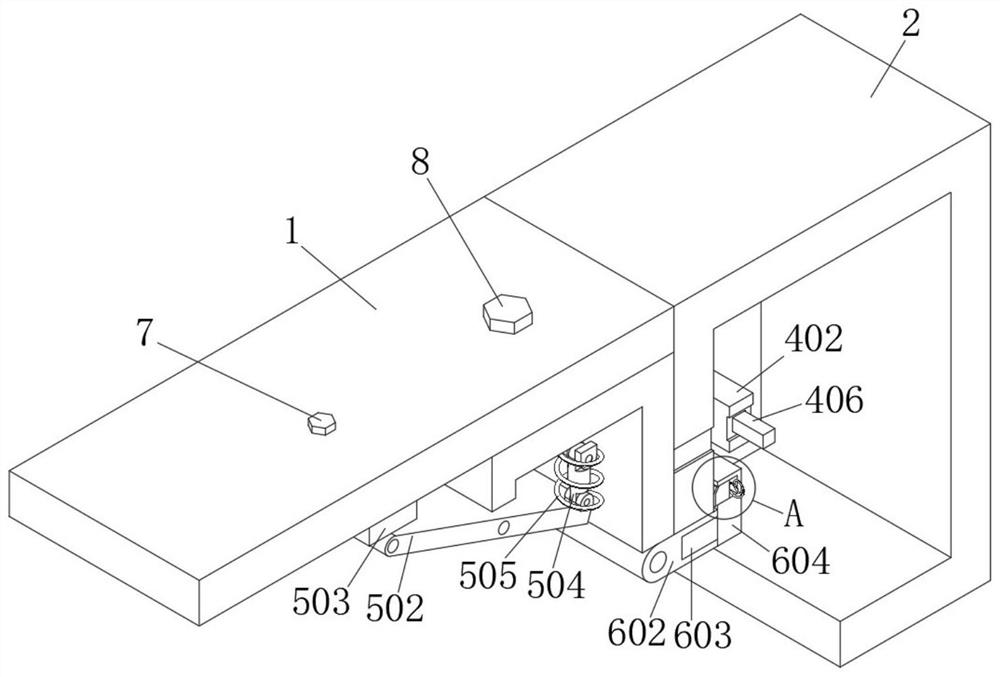

[0039] example, see Figure 1-3 and Figure 5-8 : An aluminum-wood combination mechanism for construction, comprising:

[0040]Wooden mold 1 and aluminum mold 2, the wooden mold 1 is arranged on the outer surface of one side of the aluminum mold 2, the outer surface of one side of the aluminum mold 2 is provided with two mounting holes, the connector body 3, and the connector body 3 is arranged on the one side of the aluminum mold 2. The side outer surface, and the connector body 3 is located at the bottom of the wooden mold 1, the installation mechanism 4, the installation mechanism 4 includes two installation rods 401, each installation rod 401 is fixedly connected to the outer surface of one side of the connector body 3, two installation A positioning plate 402 is movably sleeved between the outer surfaces of the rod 401, a positioning groove is opened inside the positioning plate 402, a positioning shaft 403 is rotatably connected between the inner surface walls on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com