Rapid pressurization system for spaceflight launching site

A technology of pressurization system and launch site, which is applied to non-pressure vessels, space navigation equipment, and equipment discharged from non-pressure vessels, etc. The effect of high pressure, rapid boost, atmospheric volume boost, and high-efficiency boost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to the embodiments and accompanying drawings.

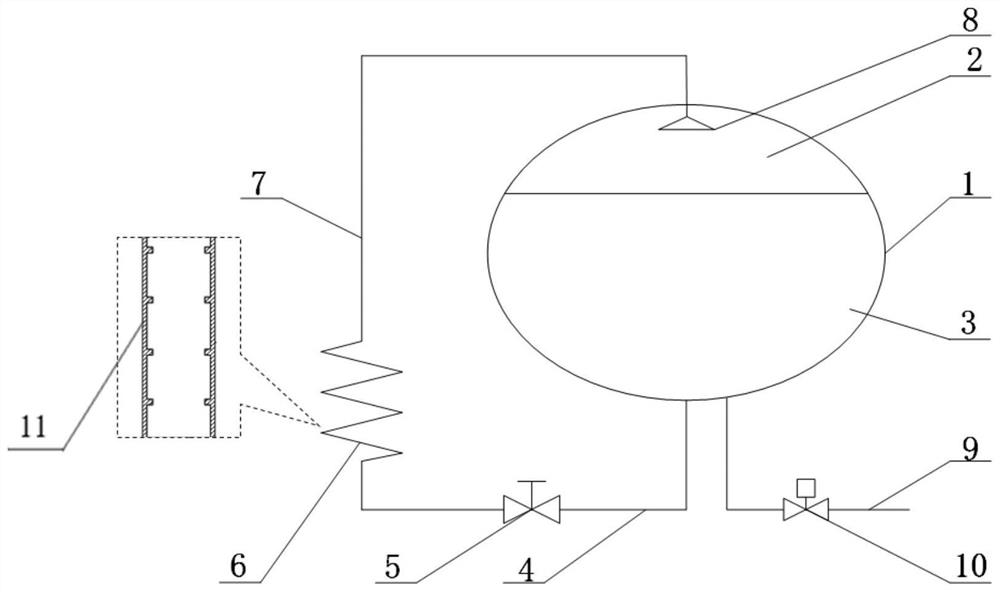

[0027] like figure 1 As shown, a rapid pressurization system for a space launch site includes a ground storage tank 1, the cryogenic liquid outlet of the ground storage tank 1 is connected to the inlet of a liquid inlet pipe 4, and the outlet of the liquid inlet pipe 4 is connected to the empty bath through a flow regulating valve 5. The inlet of the type vaporizer 6 is connected; the outlet of the air-bath vaporizer 6 is connected with the inlet of the return pipe 7, and the outlet of the return pipe 7 is connected with the energy dissipator 8 located in the top air pillow area 2 of the ground storage tank 1; the ground storage tank 1 The cryogenic liquid filling port is connected to the filling pipeline 9, and a regulating valve 10 is installed on the filling pipeline 9;

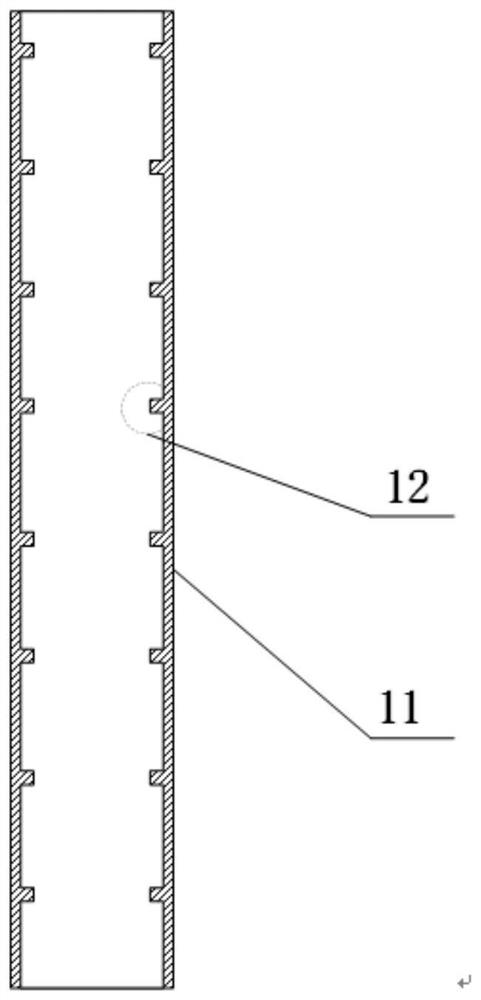

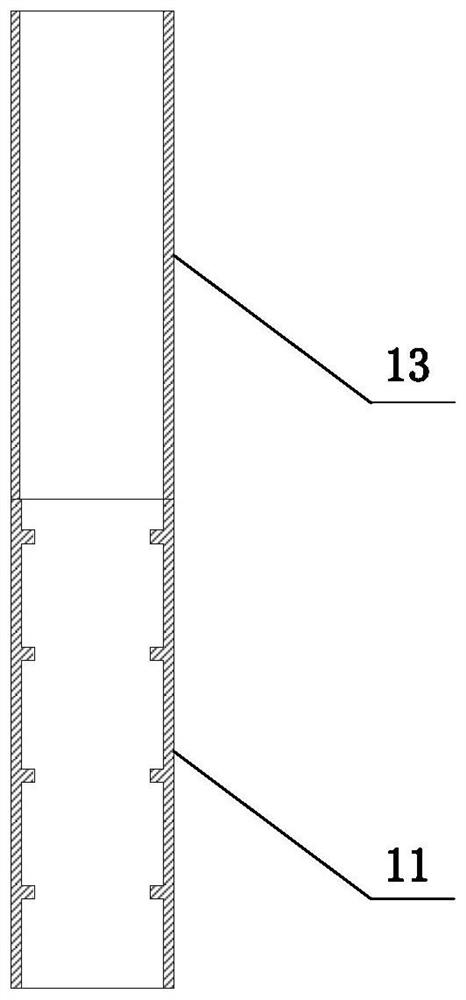

[0028] like figure 2 , image 3 As shown, the outer surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com