High-salt-content organic waste liquid treatment equipment and process method thereof

A technology for organic waste liquid and treatment equipment, applied in the direction of combustion methods, lighting and heating equipment, combustion types, etc., can solve the problems of inconvenient cleaning for staff and affecting equipment processing work, and achieve improved incineration decomposition efficiency, convenient cleaning, The effect of avoiding cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

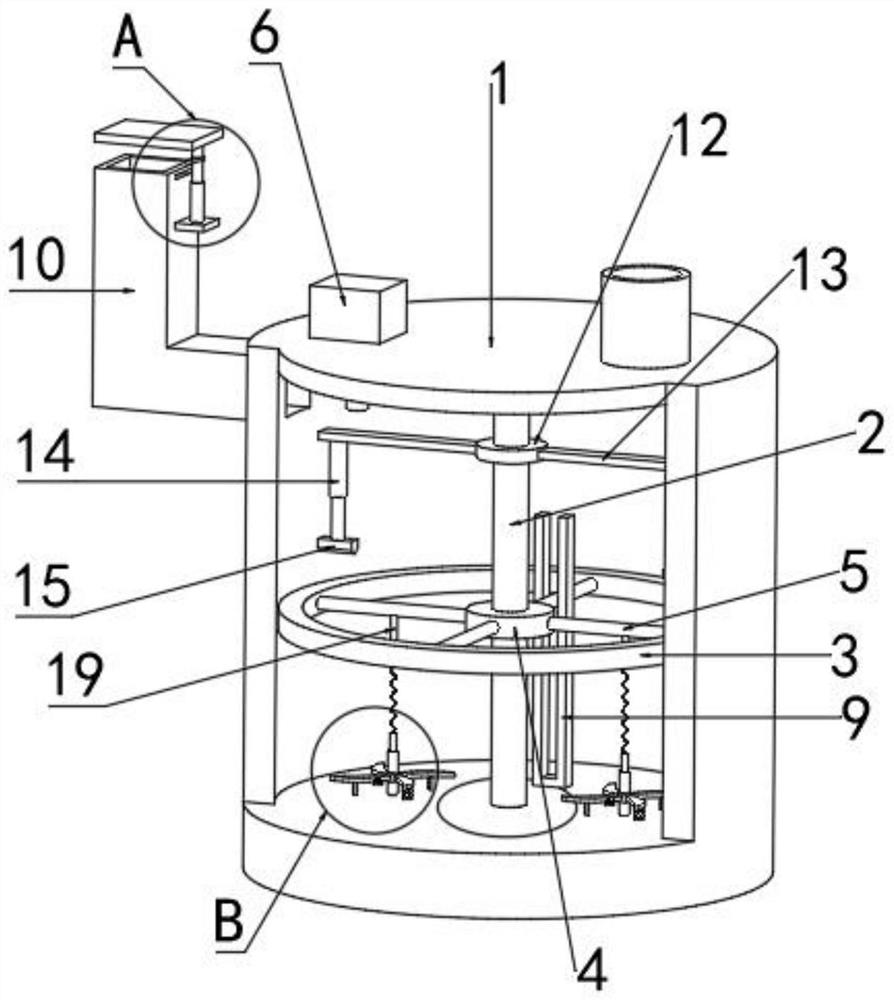

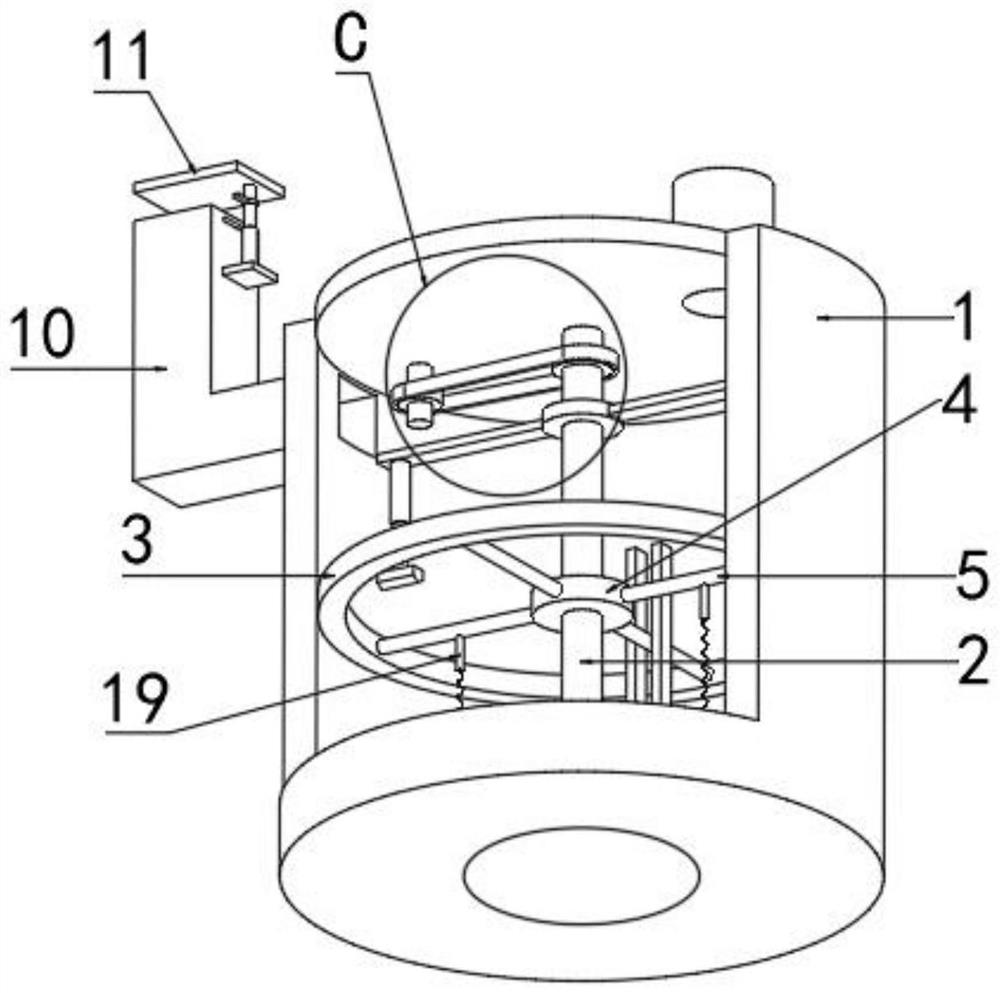

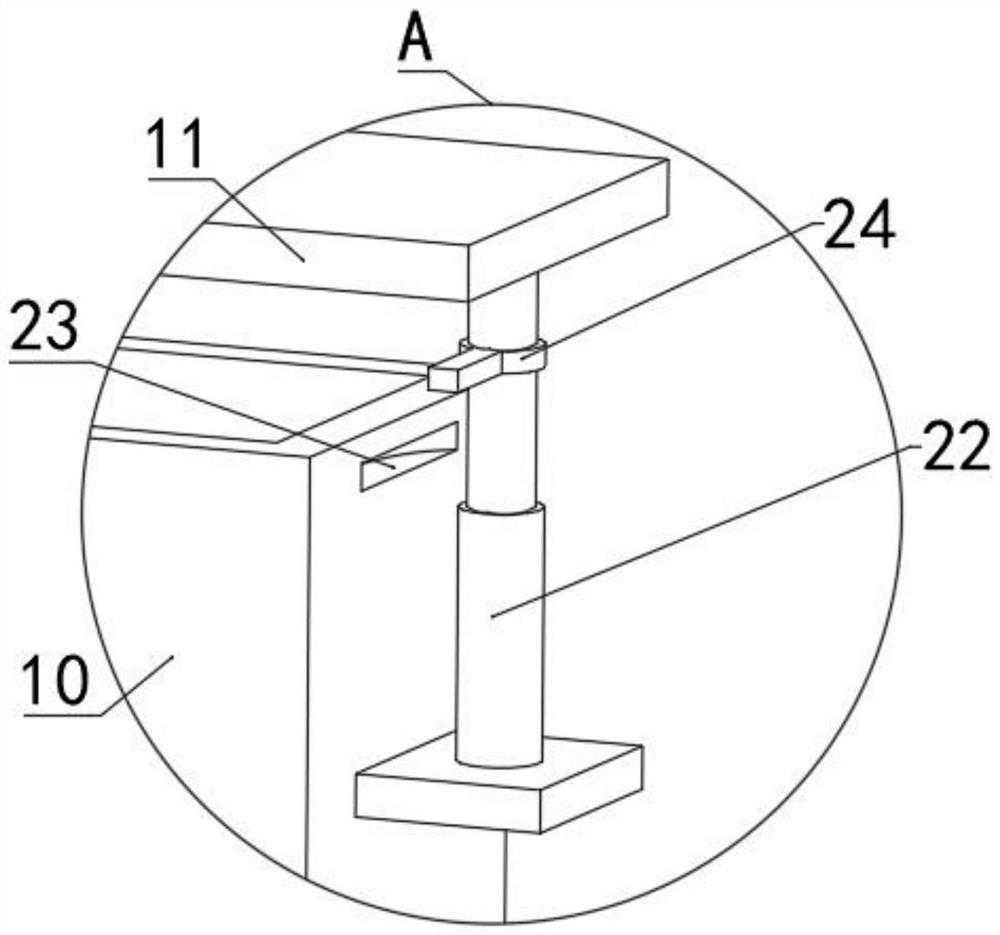

[0034] refer to Figure 1-5 , a treatment equipment for high-salt organic waste liquid, including a body 1 and a discharge port opened on the bottom surface of the body 1, and also includes:

[0035] The wall cleaning assembly is used to clean the inorganic salts attached to the inner wall of the body 1. The wall cleaning assembly includes a reciprocating screw rod 2 and a scraper ring 3 that are vertically rotated and installed in the body 1. The reciprocating screw rod 2 has a threaded sleeve. A collar 4 is connected, the outer ring wall of the collar 4 is fixedly installed with a plurality of connecting rods 5 in a circular shape, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap