Monorail type tire tread shape measuring device and measuring method thereof

A technology for measuring devices and tire treads, applied to measuring devices, instruments, etc., can solve the problems of difficulty in recording tire bumps, manual calibration of the approximate range, and time-consuming and labor-intensive problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

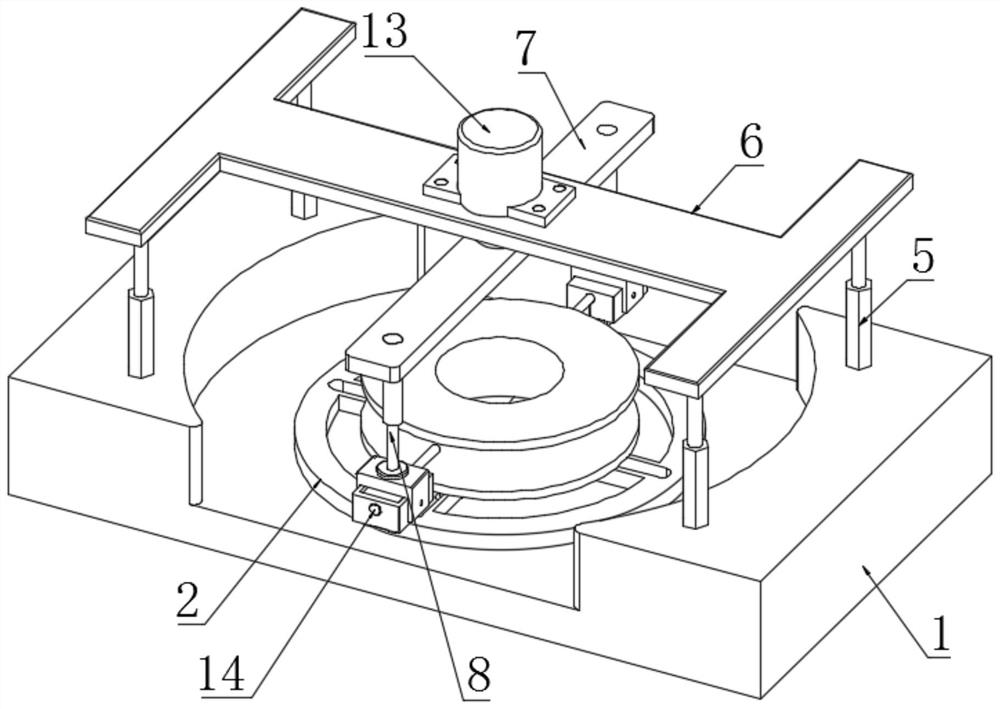

[0037] as attached figure 1 to the attached Image 6 shown:

[0038] The present invention provides a monorail type tire tread shape measuring device, comprising a test table 1 and a monorail tire 3, a rotating rod 7 is arranged on the upper part of the test table 1, a connecting rod 8 is fixedly installed on the lower part of the rotating rod 7, and the side surface of the monorail tire 3 A measuring mechanism 9 is provided. When the measuring mechanism 9 rotates, it can photograph and measure the side surface of the monorail tire 3. The upper part of the measuring mechanism 9 is fixedly connected to the lower part of the connecting rod 8. When the connecting rod 8 moves, the measuring mechanism can be driven synchronously. 9 is rotated, and the connecting rod 8 enables the measuring mechanism 9 to measure around the monorail tire 3 .

[0039]The measuring mechanism 9 includes a fixing block 901 , a nut 902 is fixedly mounted on the side of the fixing block 901 , and an ins...

Embodiment 2

[0048] Based on the monorail tire tread shape measuring device of the present invention, the monorail tire tread shape measuring method of the present invention comprises the following steps:

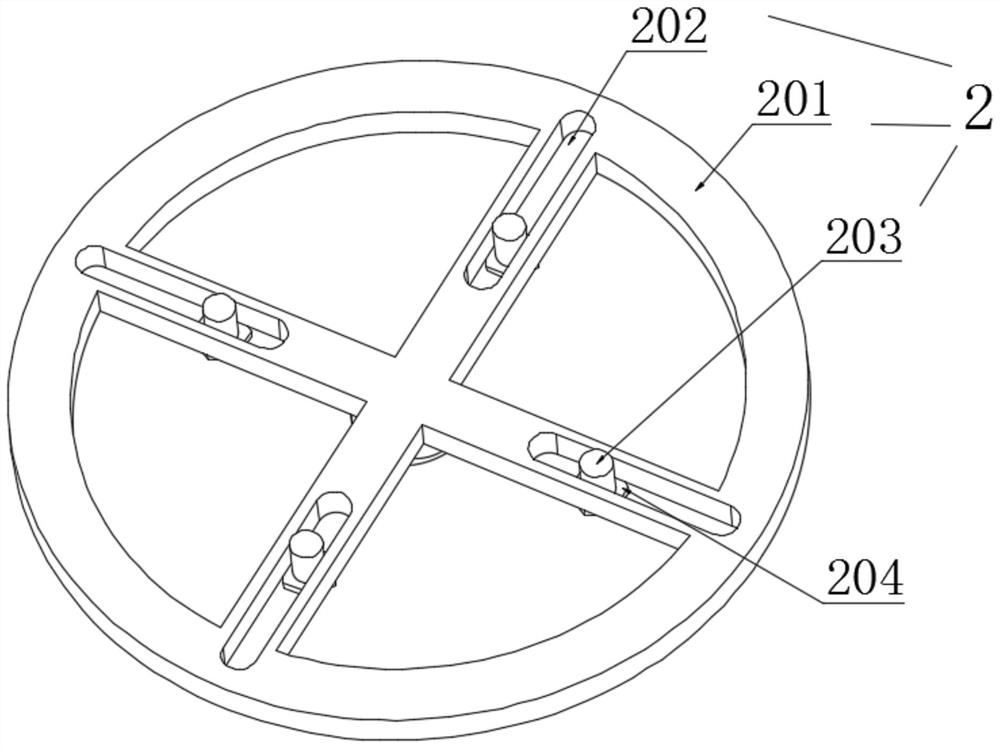

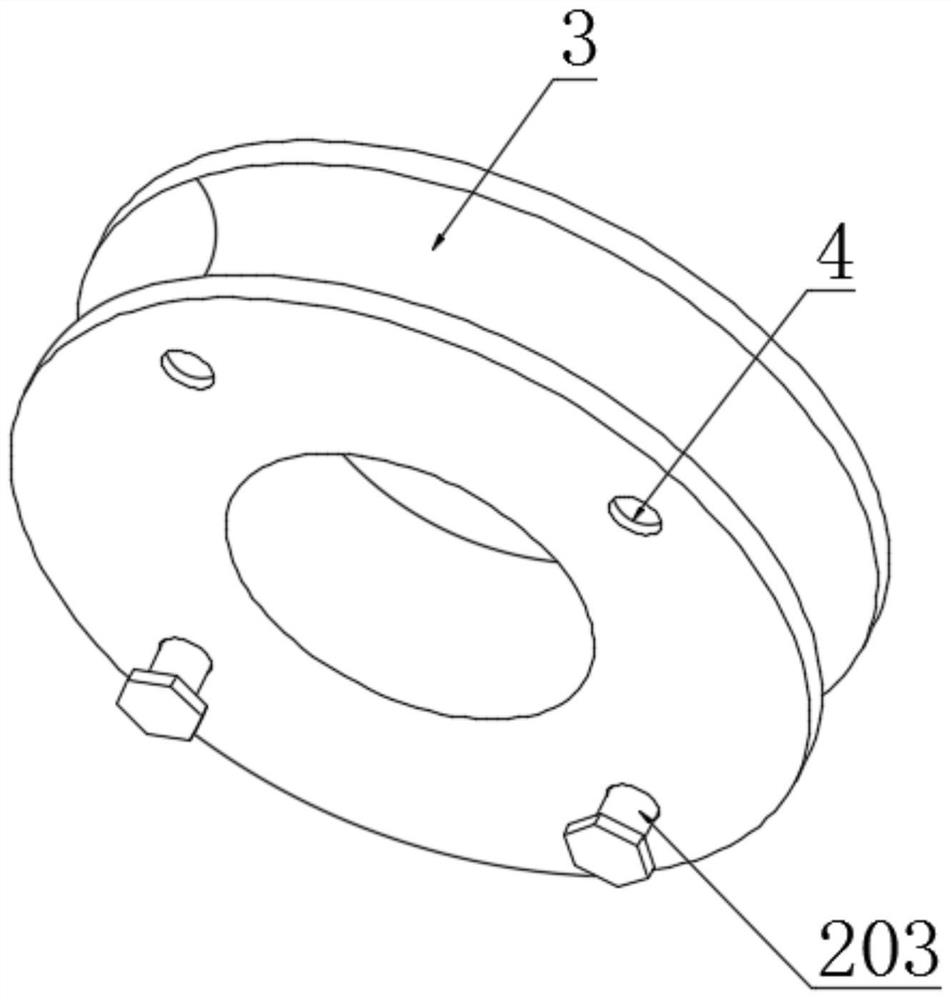

[0049] S1, firstly adjust the fixed column 203 inside the moving groove 202, so that the fixed column 203 and the fixed opening 4 correspond to each other, and connect the upper part of the fixed column 203 with the fixed opening 4 to fix the monorail tire 3;

[0050] S2. The ejector rod 910 can be positioned on the side of the monorail tire by the force of the spring 911. When the ball 12 at one end of the ejector rod 910 is in contact with the side of the monorail tire 3, the ball 12 will be stressed, and the ejector rod 910, the spring 911 and the pressure plate will be under force. 912, the force is transmitted to the pressure sensor 905, the force data is displayed on the pressure sensor 905, and then the reset button 14 is pressed to clear the reading on the pressure sensor 905;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com