Oil-immersed shunt reactor

A reactor and oil-immersed technology, applied in transformer/inductor cooling, transformer/inductor noise damping, spring/shock absorber, etc., can solve problems such as reducing the service life of reactors, human hearing damage, and aging of parts , achieve good sound insulation and shock absorption performance, accelerate heat dissipation effect, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings:

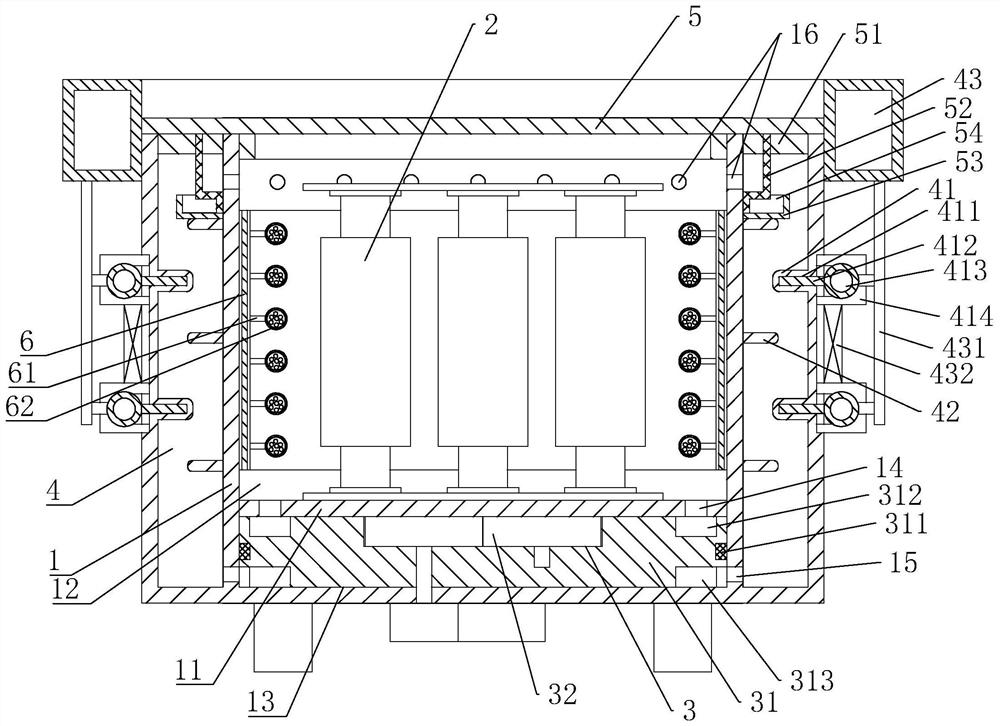

[0017] Refer to the attached figure 1 : The oil-immersed shunt reactor in this embodiment includes an oil tank 1 storing insulating oil and three parallel reactor units 2 arranged in the oil tank 1. The oil tank 1 is provided with a cooling device, and the cooling device includes The oil pump assembly 3 and the annular cooling tank 4 arranged on the periphery of the oil tank 1. The oil tank 1 is divided into an upper main oil cavity 12 and a lower auxiliary oil cavity 13 by setting the partition plate 11. The main oil cavity 12 and the auxiliary oil cavity 13 The reactor unit 2 and the oil pump assembly 3 are respectively installed inside. The oil pump assembly 3 includes an oil delivery plate 31 and a gear pump 32. A sealing ring 311 is provided between the oil delivery plate 31 and the inner wall of the auxiliary oil chamber 13. The oil delivery plate 31 The upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com