Vacuum packaging system for integrated circuit board

An integrated circuit board, vacuum packaging technology, applied in circuits, electrical components, devices for coating liquids on surfaces, etc., can solve problems such as reducing overall efficiency, occurrence of defective products, and long curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to more clearly and clearly illustrate the specific implementation purpose and implementation manner of the present invention, the technical solutions of the present invention will be fully described below, and the described embodiments are a part of the embodiments of the present invention, rather than all the embodiments. On the premise that no creative work is made, all other embodiments based on the described embodiments of the present invention belong to the protection scope of the present invention.

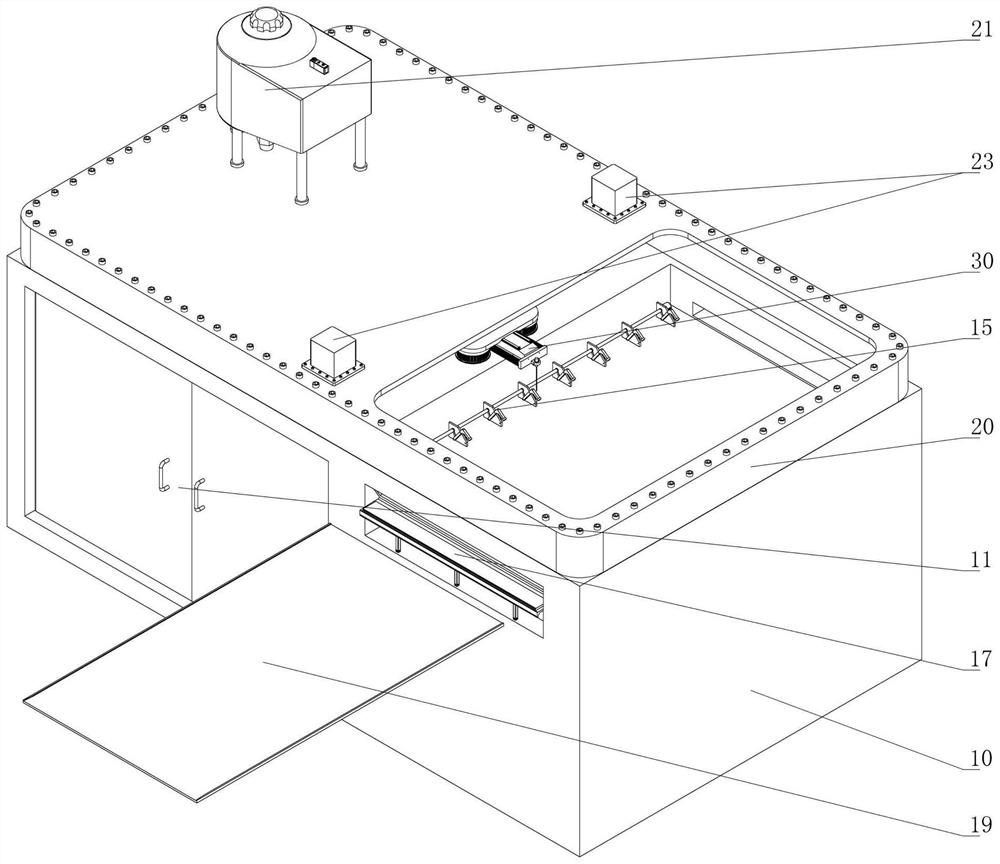

[0047] The integrated circuit board vacuum packaging system of the present invention, such as figure 1 As shown, it includes: a cabinet body 10 arranged on the ground for built-in electrical control components, the upper end of the cabinet body 10 is sealed with a cover body 20, and the lower bottom of the cover body 20 is configured as an inward concave shape, which is fixed inside. And a translation mechanism 30 is accommodated.

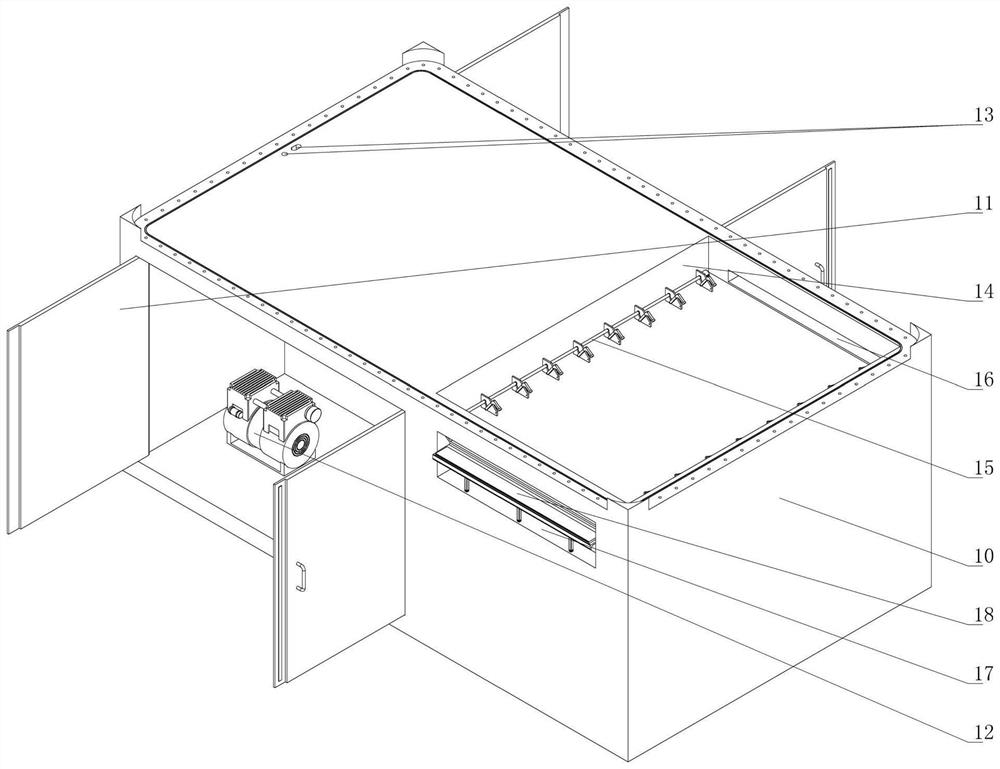

[0048] like figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com