PCB stacking method based on weight measurement

A PCB board and weight measurement technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of circuit board production scrap, error-prone, increased production costs, etc., to achieve the effect of ensuring the correct rate of pass, type and stacking sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

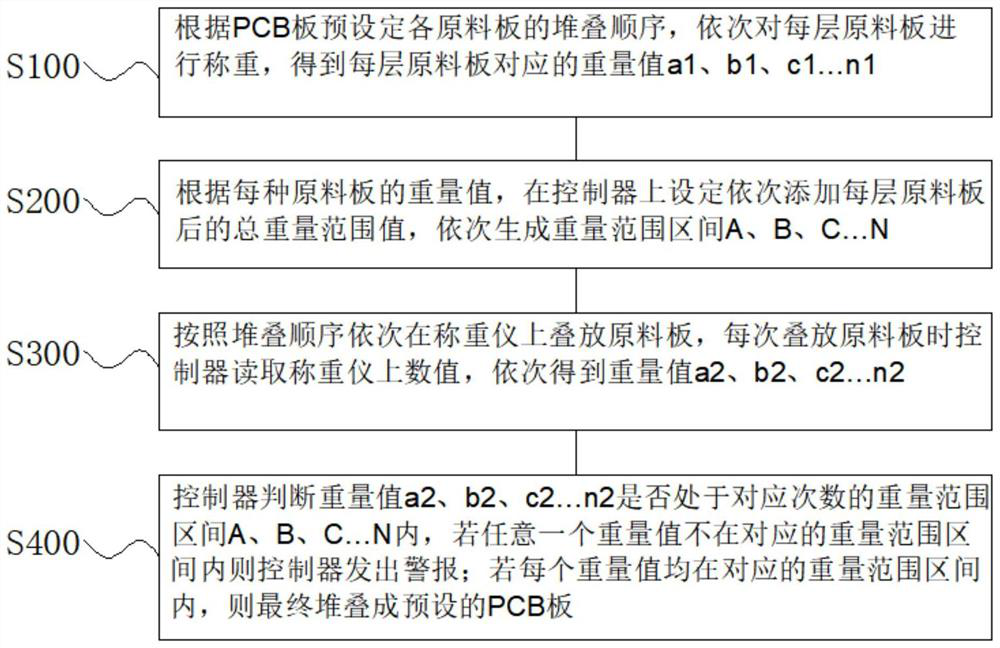

[0016] In order to solve the above technical problems, this embodiment provides a method for stacking PCB boards based on weighing, based on a controller and a precision weighing instrument provided with an alarm, the controller and the precision weighing instrument are connected by signals, and then the controller Can read measurement data on precision weighing scales, such as figure 1 shown, including the following steps:

[0017] S100 , pre-setting the stacking sequence of each raw material board according to the PCB board, and weighing each layer of raw material boards in turn to obtain weight values a1, b1, c1...n1 corresponding to each layer of raw material boards;

[0018] According to the structural requirements of the customer's final PCB board, the stacking sequence of each raw material board is designed, wherein each raw material board may include No. 1 core board, No. 2 core board, No. 3 core board, etc., as well as No. 1 prepreg, No. 2 prepreg Etc., the weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com