Method for cleaning inner wall of discharge pipe, slurry discharge device, food processor and medium

A discharge pipe and cleaning technology, which is applied in the directions of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of limited, easily deteriorated and smelly food slurry, and poor cleaning effect of the discharge pipe, etc. The effect of increasing the flow rate of clean water and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

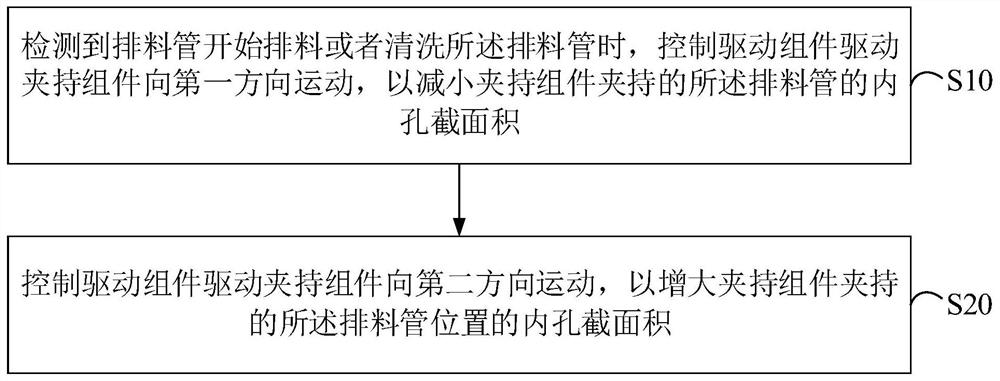

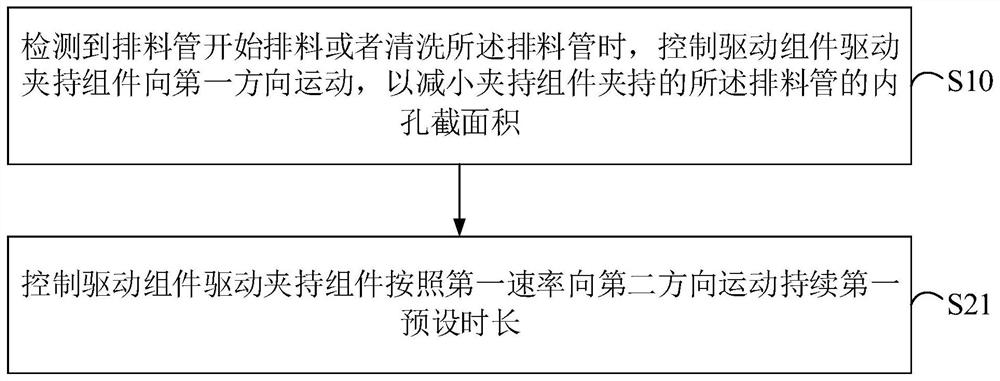

[0050] The embodiment of the present invention provides a solution, by reducing the cross-sectional area of the inner hole of the discharge pipe during the discharge or cleaning process of the discharge pipe, so as to increase the flow rate of food slurry or clean water in the discharge pipe, and reduce the The stickiness of the small food slurry on the inner wall of the discharge pipe can improve the cleaning ability of clean water on the inner wall of the discharge pipe, thereby improving the cleaning effect of the inner wall of the discharge pipe.

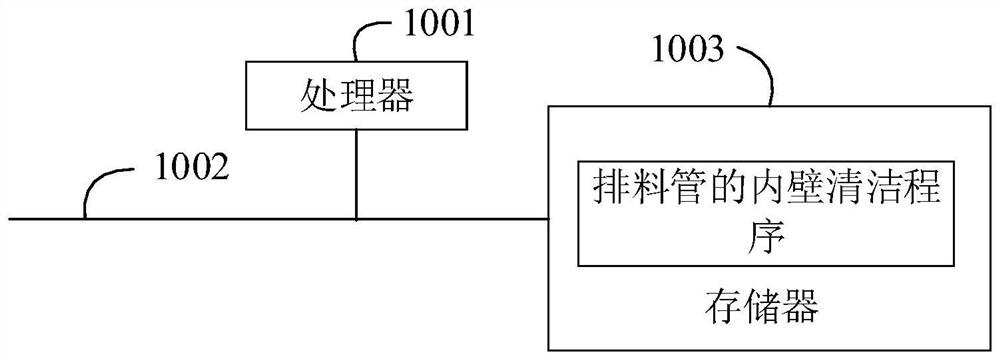

[0051] like figure 1 shown, figure 1 It is a schematic diagram of the terminal structure of the hardware operating environment involved in the solution of the embodiment of the present invention.

[0052]The terminal in the embodiment of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com