Novel vibration type shakeout machine for sand mold casting

A sand casting and vibrating technology is applied in the field of new vibrating shakeout for sand casting, which can solve the problems of large machine loss, low efficiency of the shakeout, and low efficiency of the shakeout, so as to improve production efficiency, The effect of improving stability and improving the efficiency of sand removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment, the present invention is described in further detail, but the protection scope of the present invention is not limited to this.

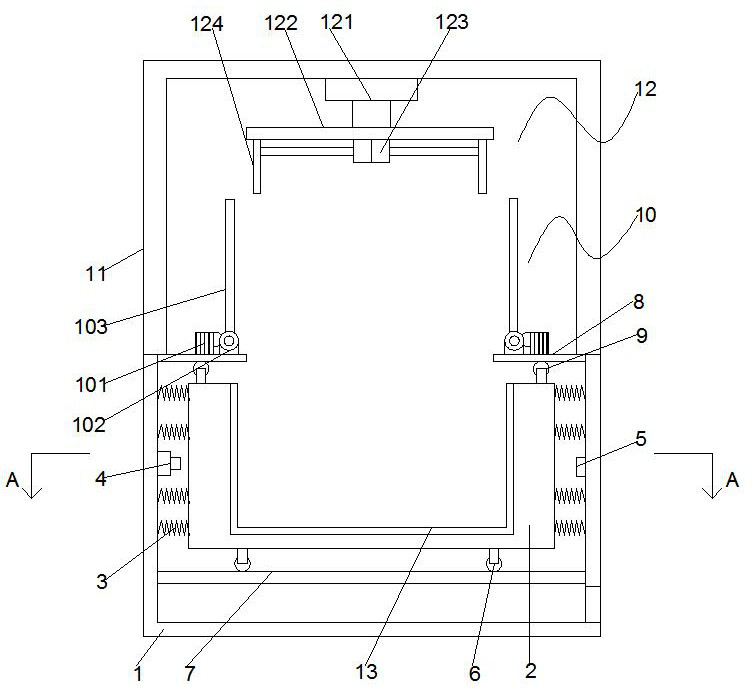

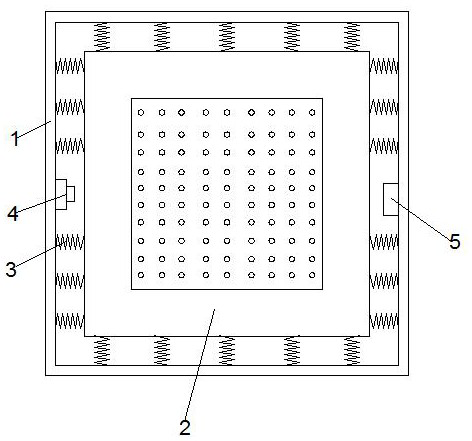

[0018] The invention relates to a novel vibrating shakeout machine for sand casting, comprising a casing 1, a screen cylinder 2 is arranged inside the casing 1, a plurality of springs 3 are arranged between the screen cylinder 2 and the casing 1, and the inner side of the casing 1 is provided with a plurality of springs 3. One end of the wall is provided with a first hydraulic cylinder 4, the other end is connected with a distance sensor 5, the bottom of the screen cylinder 2 is connected with a first universal wheel 6, the first universal wheel 6 is connected with the bottom plate 7 in rolling connection, and the bottom plate 7 is connected with the housing 1 The inner side walls are fixedly connected, the upper two ends of the inner side of the housing 1 are respectively connected with a fixed plate 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com