Preparation method of biological drag reducer for conveying high-freezing-point and high-viscosity crude oil

A drag reducer, biological technology, applied in the field of preparation of biological drag reducer for high-condensation and high-viscosity crude oil transportation, can solve the problems of high energy consumption, lack of ecological sustainability, toxic by-products, etc. Performance, less risky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

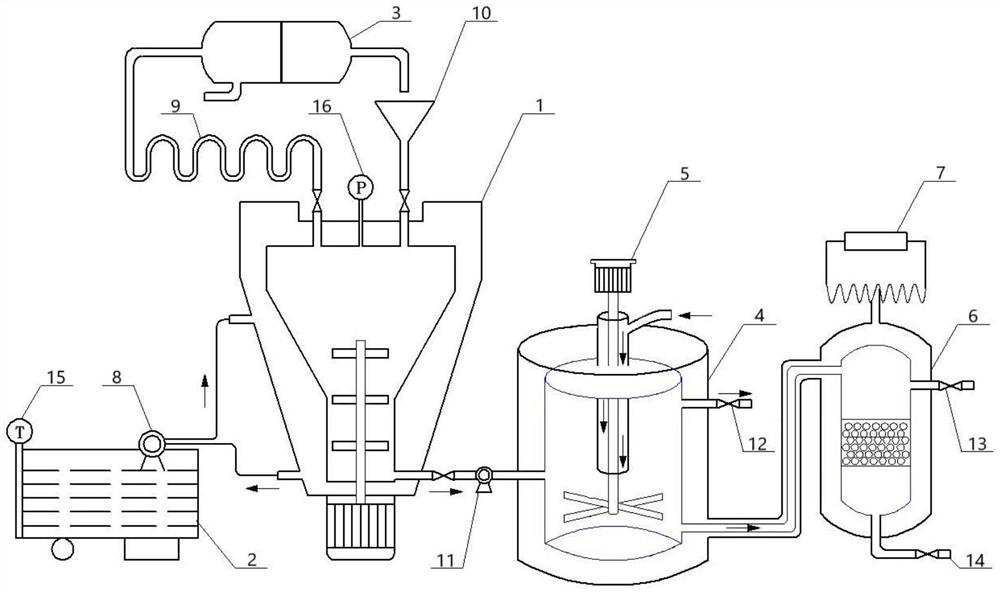

Method used

Image

Examples

Embodiment 1

[0054] Adopt the preparation method of the biological drag reducing agent for high-point and high-viscosity crude oil transportation according to the present invention:

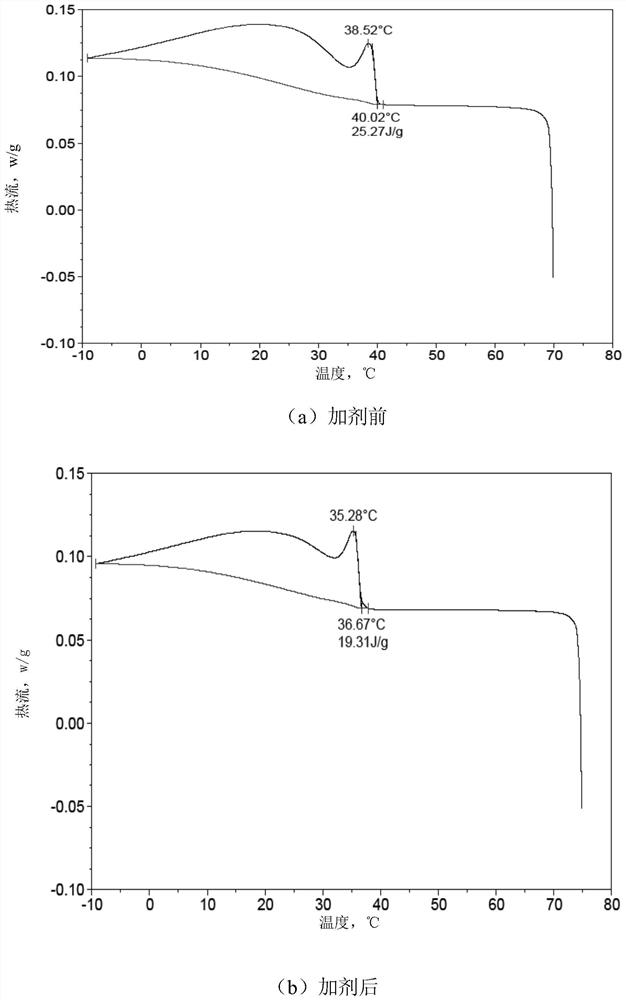

[0055] Dodecanoic acid (C 12 H 24 O 2 ) and glycerol (C 3 H 8 O 3 ), immobilized lipase with a mass fraction of 0.5% was added, and the reaction was carried out at a temperature of 70 ° C for 30 hours. The waxy crude oil with a water content of 75% has a freezing point of 30.2 °C, a viscosity of 172.7 mPa.s at 40 °C, a wax precipitation point of 40 °C, and a wax content of 23.7%.

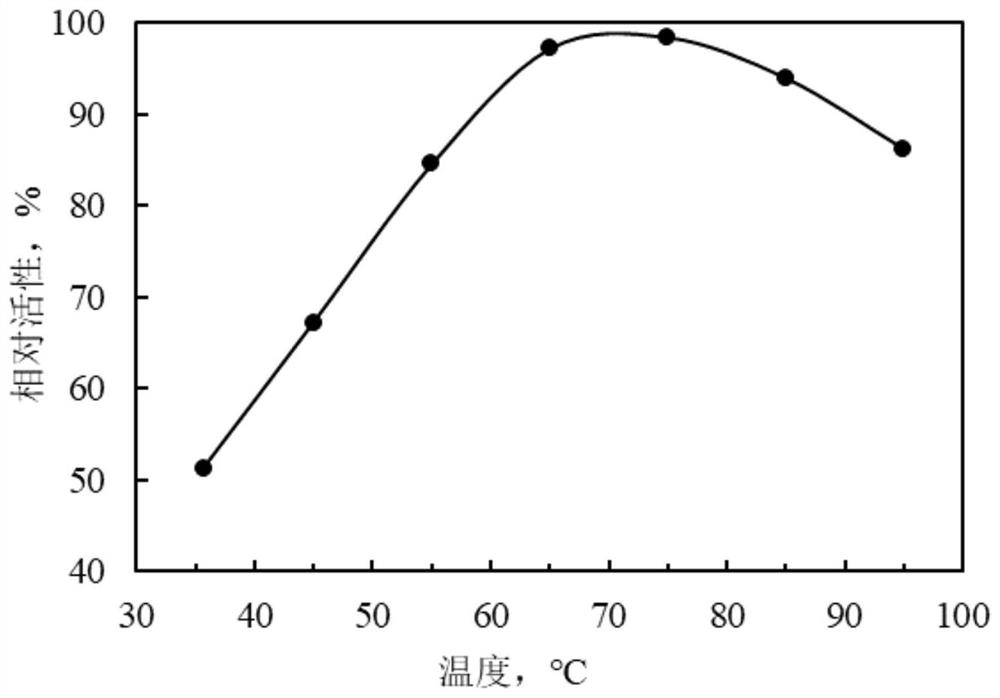

[0056] figure 2 The relative activity of lipase immobilized by the carrier-binding method varies with temperature, and it can be seen that the highest yield is 91% at 70°C. At the same time, the generation of water during the esterification preparation of biological drag reducing agent is beneficial to activate the activity of the enzyme, but the excessive accumulation of water will cause the reaction to reach equilibrium i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap