Lightweight automatic threading device

A light-weight technology for threading and threading, applied in the field of needlework, can solve problems such as inconvenient, not strong enough tails, and difficulty in threading needles, etc., and achieve the effect of simple and scientific structure, convenient storage and storage, and low vision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention and its beneficial technical effects will be described in further detail below with reference to the accompanying drawings.

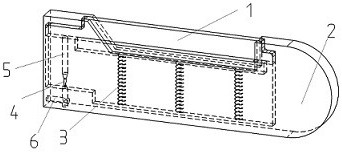

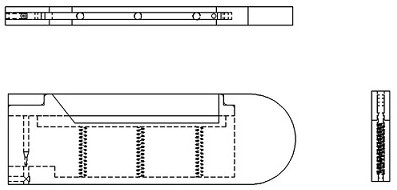

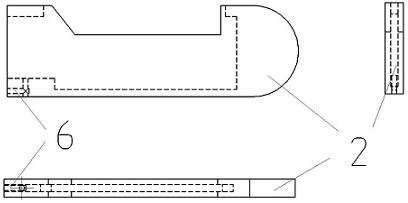

[0019] see figure 1 , 2 , 3, 4, 5, 6, a lightweight automatic needle threader of the present invention, which includes image 3 fixed shell and Figure 5 threading mechanism, image 3 The fixed shell includes a limit port 5 for positioning and limit functions, and the limit port is a cylinder; the threading structure includes a needle threading slider 1 and a thread hooking mechanism 4. The needle threading slider can be moved up and down in the shallow groove in the middle of the fixed casing. Moving, the shallow groove has the function of fixing and limiting; the spring device 3 presses the needle threading slider by the force of the hand, the spring uses its own elastic force to pass the thread hooking mechanism through the needle port, and uses the reaction force to provide the driving force. The hooking mechanism in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com