New energy automobile thermal management system and new energy automobile

A new energy vehicle and thermal management system technology, applied in the thermal management system of new energy vehicles and the field of new energy vehicles, can solve the problems of untimely heat dissipation of the battery pack and spontaneous combustion of the battery pack, so as to accelerate heat loss, realize cooling, and reduce mutual effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A thermal management system for a new energy vehicle, comprising:

[0030] The sensor group is used to realize the temperature parameter of the battery pack, the deformation parameter of the battery pack and the working condition parameter of the battery pack;

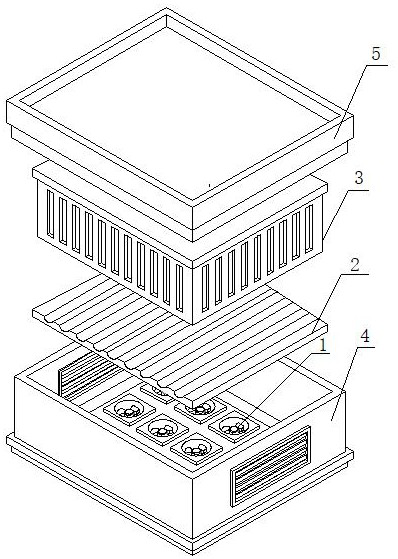

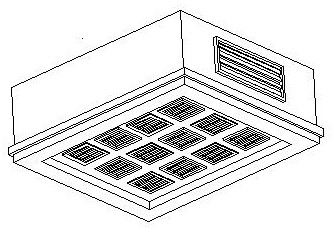

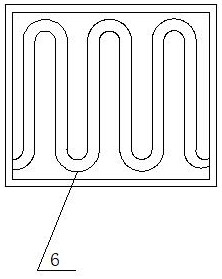

[0031] cooling systems such as Figure 1-Figure 4 As shown, it includes a cooling plate 1 arranged at the bottom of the battery pack, a cooling fan installed in the cooling plate, a wave-shaped thermally conductive silicone sheet 2 arranged between the cooling plate and the bottom surface of the battery pack, and a pulsating heat pipe wrapped around the battery pack. 3. The thermally conductive silicone sheet arranged between the pulsating heat pipe 3 and the battery pack, the silicone thermally conductive insulating sheet 7 arranged between the battery packs, and the cooling pipeline 6 arranged on the top of the battery pack are used to realize the heat dissipation of the battery pack Treatment; the battery pa...

Embodiment 2

[0037] A new energy vehicle includes the new energy vehicle thermal management system described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com