10MW three-time reheating reaction type air turbine

An air turbine and reactionary technology, applied to engine components, machines/engines, safety devices, etc., can solve the problems of air turbines such as less reheating times, unreasonable design structure, inflexible start-up and operation, etc., and achieve aerodynamic efficiency Optimum, reasonable geometric dimensions, low thermal stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

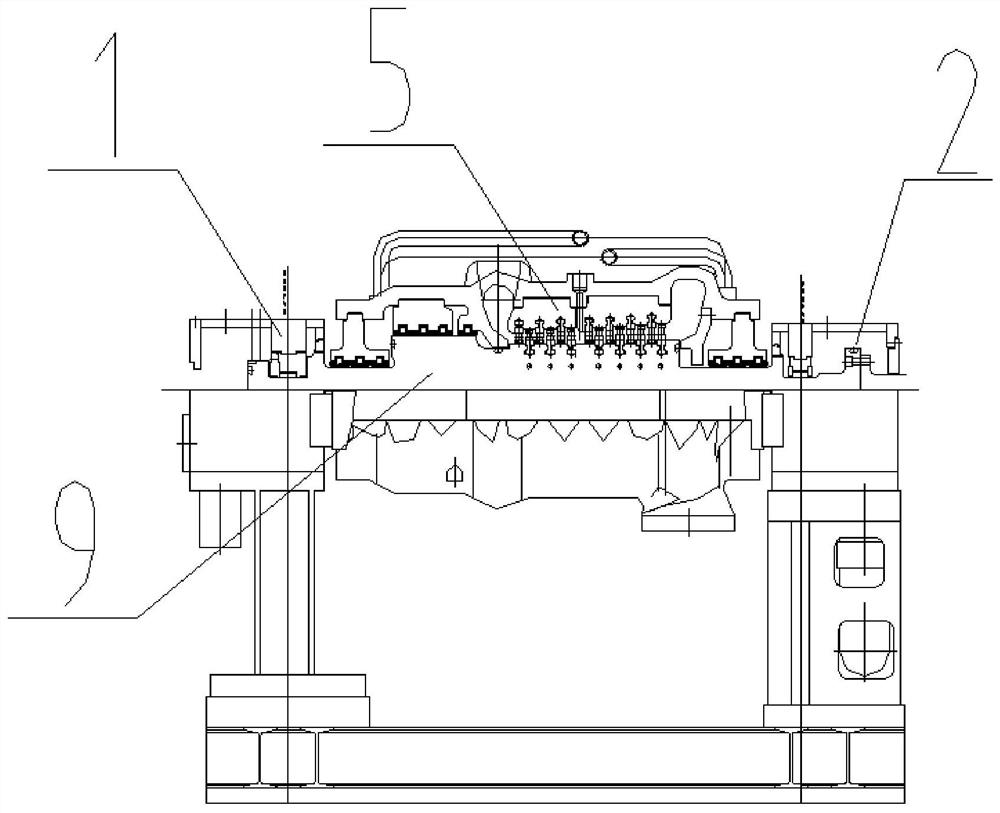

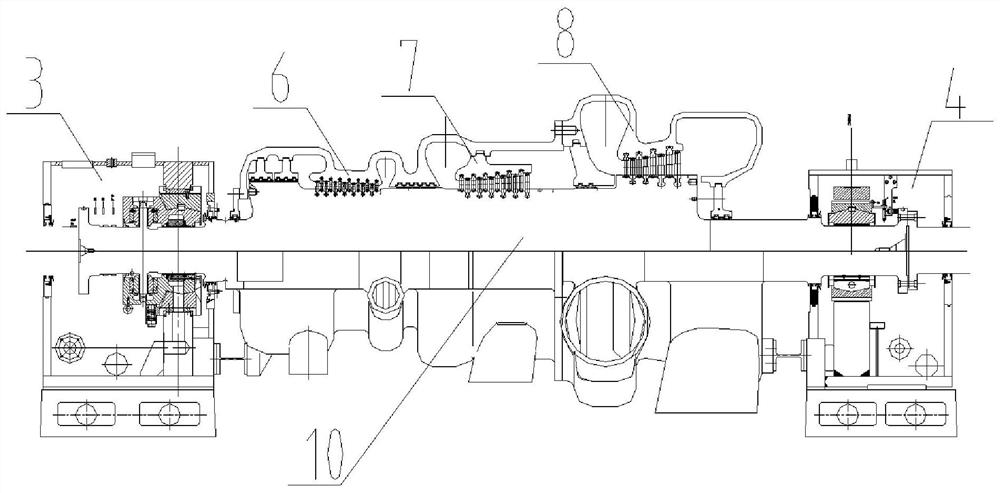

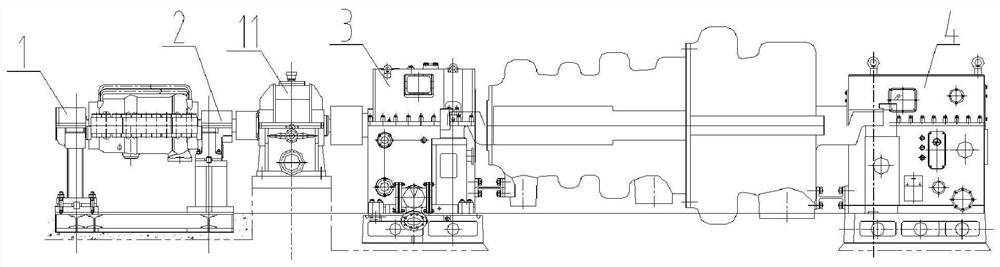

[0019] Embodiment 1: Combining Figure 1-Figure 4 Illustrating this embodiment, the 10MW three-time reheating reaction air turbine includes a high-speed module, a conventional speed module, a gearbox 11, a No. 1 turbine intake regulating valve 12, and a No. 2 turbine intake pipe 13 , No. 3 turbine intake pipe 14 and No. 4 turbine intake pipe 15; the high-speed module includes No. 1 bearing housing 1, No. 1 turbine cylinder 5, No. 2 bearing housing 2 and high-speed rotor 9, and the conventional speed module includes 3 No. 3 bearing box, No. 2 turbine cylinder 6, No. 3 turbine cylinder 7, No. 4 turbine cylinder 8, No. 4 bearing box 4 and conventional speed rotor 10;

[0020] The No. 1 bearing box 1 is arranged near the intake side of the No. 1 turbine cylinder 5, the No. 2 bearing box 2 is arranged near the exhaust side of the No. 1 turbine cylinder 5, and the high-speed rotor 9 is arranged on the No. 1 bearing box 1 and No. 1 turbine. Inside the bearing housing 2 of cylinder N...

specific Embodiment approach 2

[0023] Specific implementation mode 2: Combining Figure 1-Figure 4 Illustrating this embodiment, a 10MW three-time reheating reaction air turbine described in this embodiment, the turbine as a whole is a dual-speed design. The high-speed rotor 9 reduces the speed to 3000r / min through the gearbox 11, and then is connected to the normal speed rotor 10, and the overall output speed of the turbine is 3000r / min. Other compositions and connection modes are the same as in the first embodiment.

[0024] In this embodiment, the selection of a reasonable rotation speed can make the geometry size of the through-flow blades of each stage of the turbine the most reasonable, the aerodynamic efficiency is the best, and the overall power generation efficiency is higher.

specific Embodiment approach 3

[0025] Specific implementation three: combination Figure 1-Figure 4 Illustrating this embodiment, a 10MW three-reheat reaction air turbine described in this embodiment also includes 24-stage small enthalpy drop blades, 7-stage blades are installed inside the No. 1 turbine cylinder 5, and 7-stage blades are installed in the Inside the No. 2 turbine cylinder 6, the sixth stage vane is installed inside the No. 3 turbine cylinder 7, and the fourth stage vane is installed inside the No. 4 turbine cylinder 8. Other compositions and connection methods are the same as those in the first embodiment.

[0026] This embodiment adopts the multi-stage small enthalpy drop design technology, and the unit has many blade stages, small enthalpy drop, and high reheat efficiency, which can fundamentally improve the overall efficiency of the unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com