Car Seat Torsion Tube Cold Extrusion Die

A torsion tube and cold extrusion technology, which is applied in the field of car seat torsion tube cold extrusion dies, can solve the problems of insufficient reference data and difficult implementation of cold extrusion die technology, and achieve reasonable geometric shape and good economy and social benefits, easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

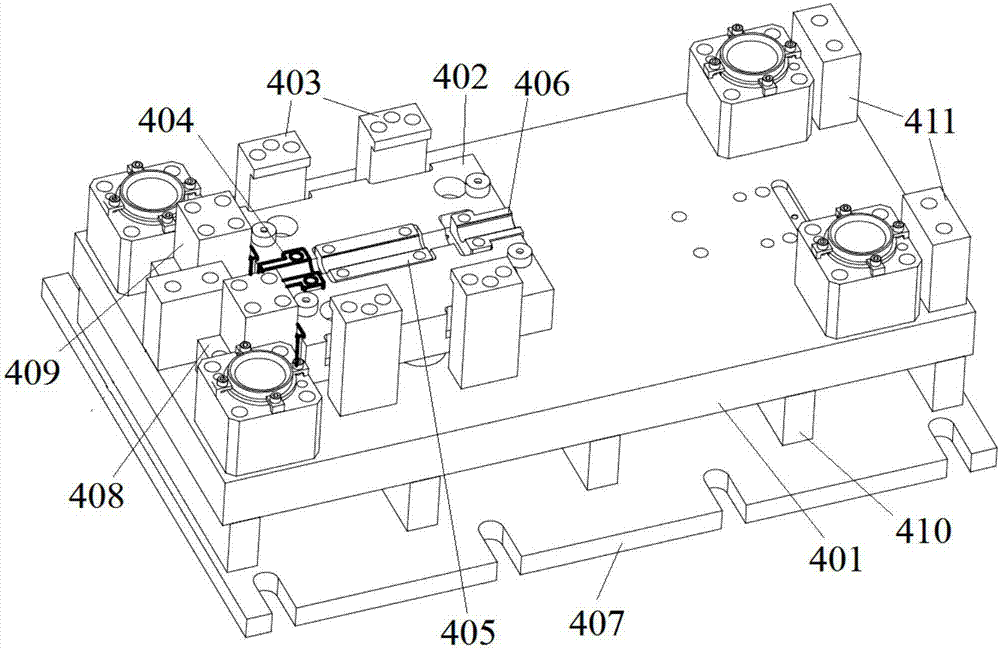

[0032] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

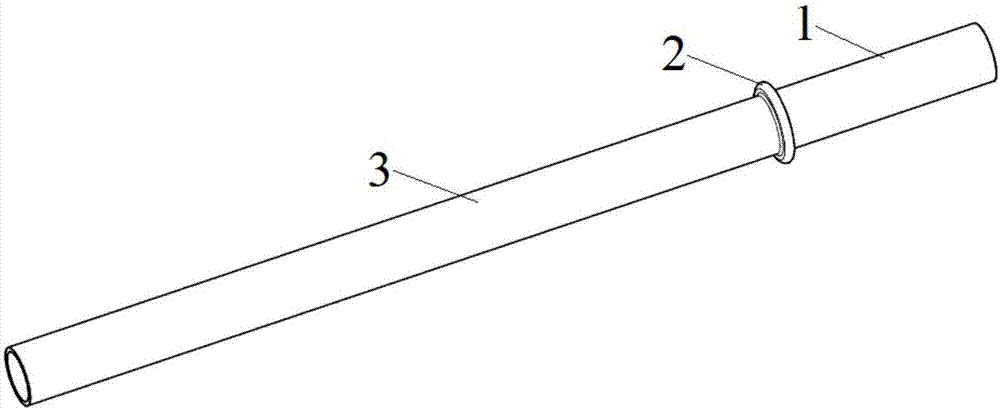

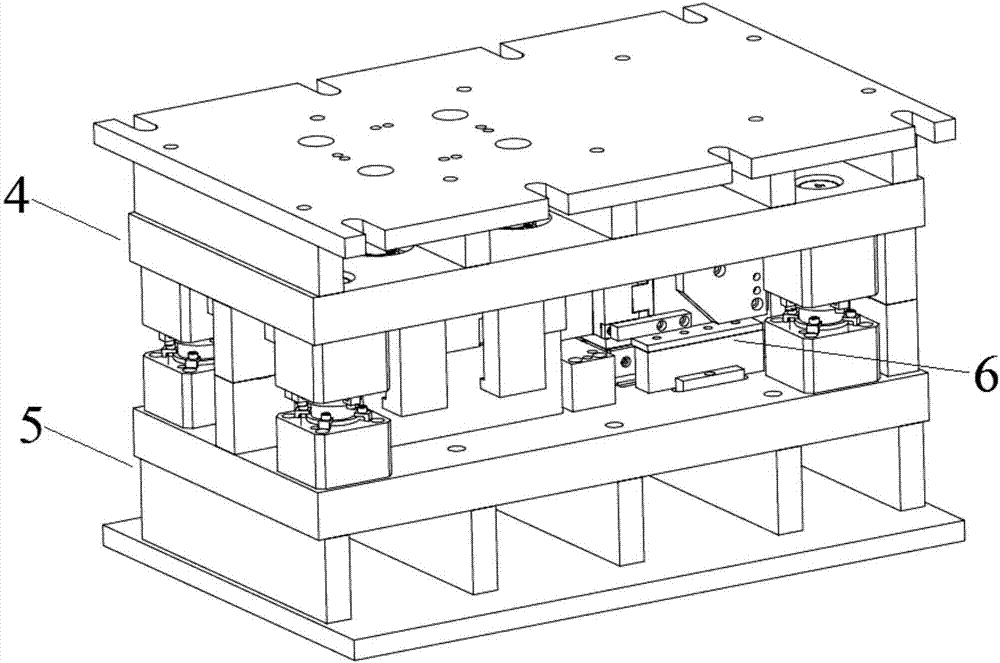

[0033] As an important component of automotive interiors, seats have always been the key to comfortable driving and have received great attention. As the basic frame of a car seat, the car seat frame is an auto part that is in direct contact with people, and needs to meet certain comfort and safety requirements. Because cold extrusion technology has the most effective advantages of saving materials, improving production efficiency, improving mechanical product performance, and being suitable for mass production, cold extrusion technology is widely used in car seat frame products. like Figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com