Steel rotational molding PFA vertical storage tank

A vertical storage tank and riser technology, which is used in fixed-capacity gas storage tanks, gas/liquid distribution and storage, container filling methods, etc., can solve problems such as difficulty in meeting work needs, single air intake method, and unsatisfactory effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

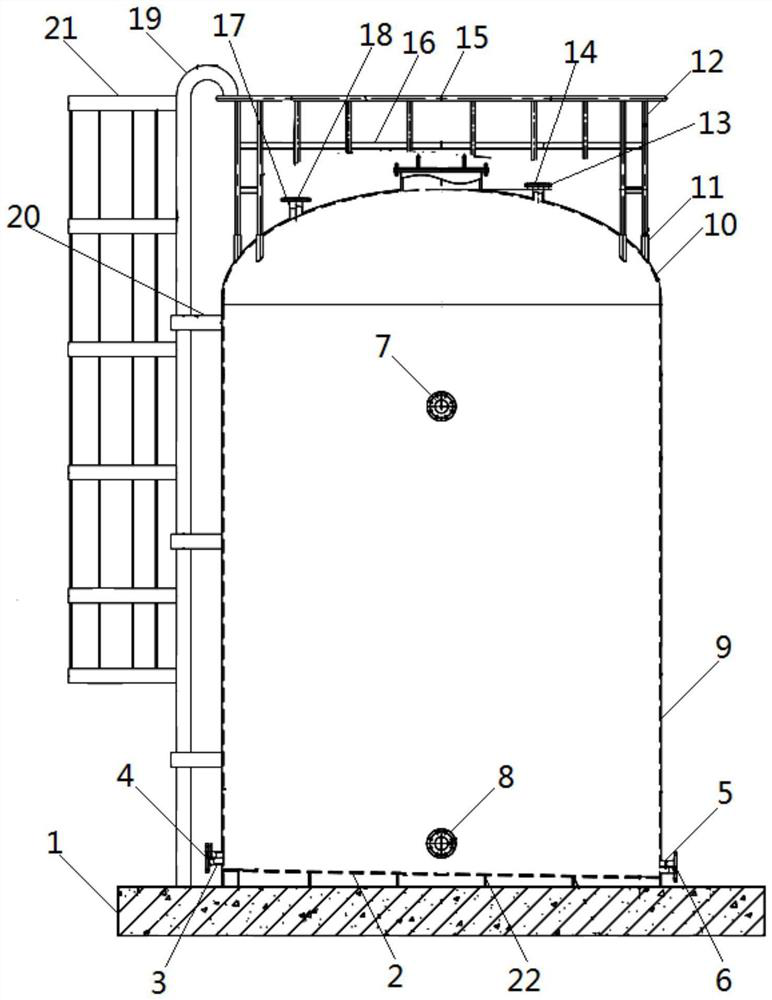

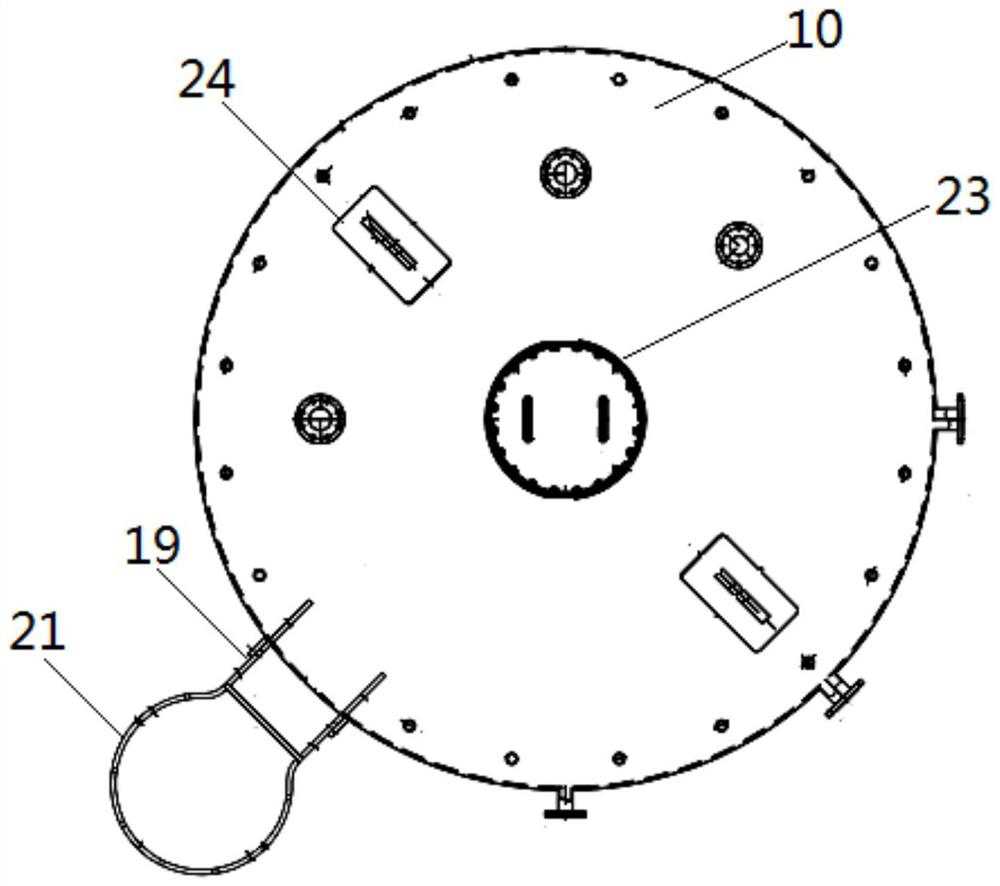

[0015] The invention provides a steel rotomolding PFA vertical storage tank, such as figure 1 As shown, it includes reinforced concrete 1, the top of the reinforced concrete 1 is fixed with a bottom plate 2, the top of the bottom plate 2 is fixed with a cylinder 9, the top of the cylinder 9 is connected with a cylinder cover 10, and the side is connected with a first pipe 3, The second pipe 5 and the two third pipes 7, the first pipe 3 and the second pipe 5 are located opposite to each other, and the other ends are respectively fixed with a first flange 4 and a second flange 6, and the two The other end of the three pipes 7 is fixed with a third flange 8; the cylinder cover 10 is connected with a number of fence intubation pipes 11, a fourth connection pipe 13 and a fifth connection pipe 17, and the other ends of the fence intubation pipes 11 are connected with The fence riser 12, the fourth flange 14 and the fifth flange 18 are respectively fixed at the other ends of the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com