Gas electric heating device

An electric heating device and gas technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low heat exchange efficiency of heaters, achieve high heat exchange efficiency and safety, simple structure, The effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

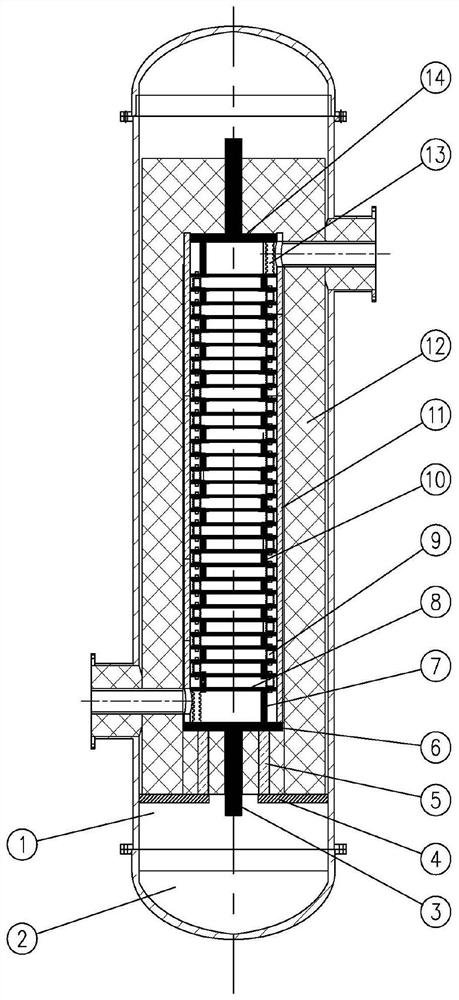

[0028] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0029] like figure 1 As shown, the gas electric heating device of the present invention includes a pressure outer cylinder 1, which is a metal cylindrical pressure vessel, and the openings at both ends of the pressure outer cylinder 1 are bolted with a head flange 2, and the pressure outer cylinder 1 and the sealing A gasket is abutted between the head flanges 2, which reduces the friction between the pressure outer cylinder 1 and the head flange 2, and increases the sealing performance. The inner cavity of the pressure outer cylinder 1 is fixed with a bottom near the bottom. The support fixing plate 4, the center of the bottom support fixing plate 4 is provided with a through hole, the upper surface of the bottom support fixing plate 4 is abutted with a refractory insulating support cylinder 5, and the refractory insulating support cylinder 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com