Compression resistance testing device for building materials

A technology for building materials and testing devices, which is used in measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure. It can solve problems such as operator injury, lack of protective function, etc. Bit, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

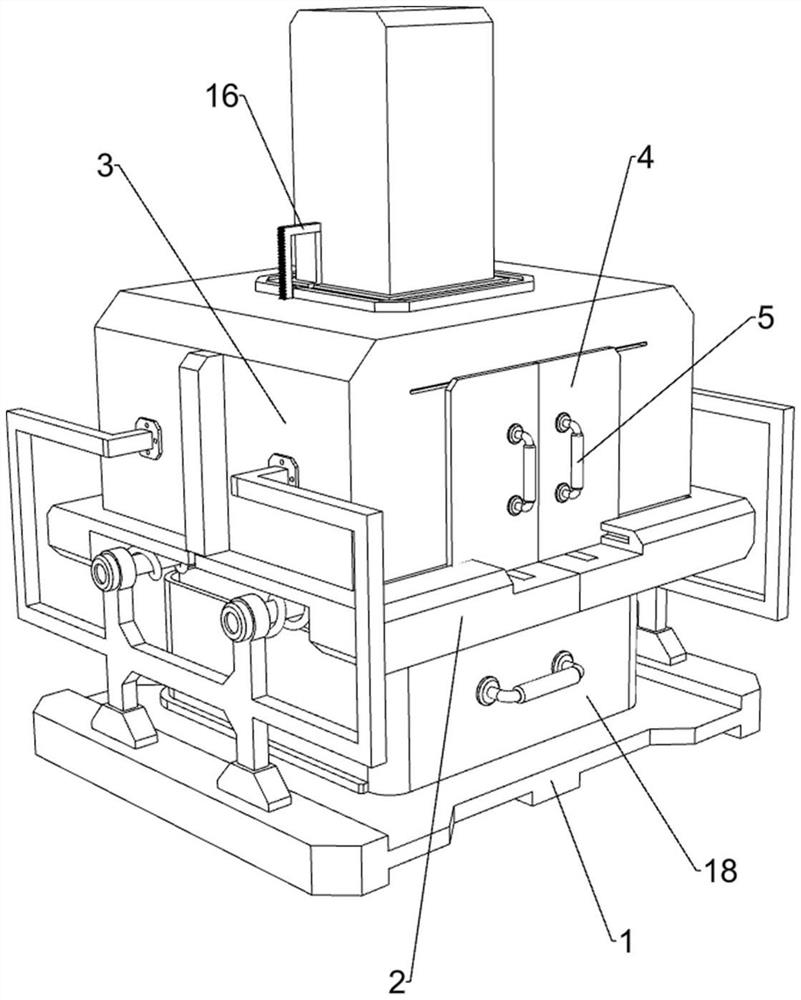

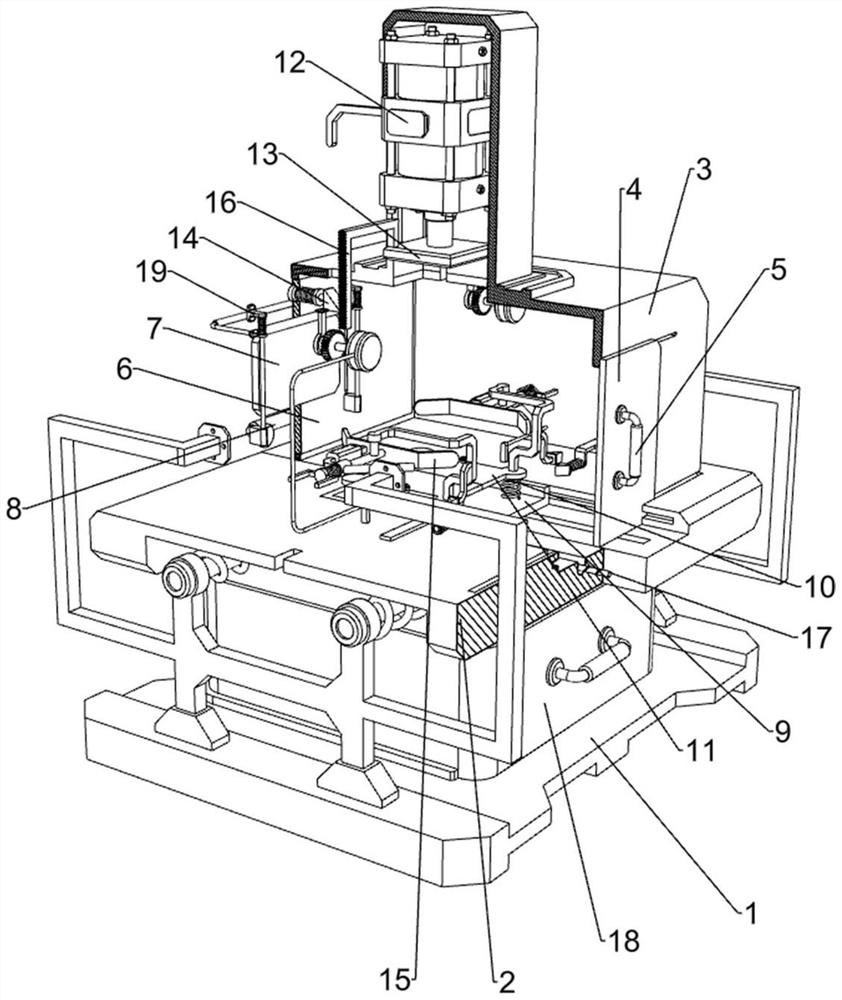

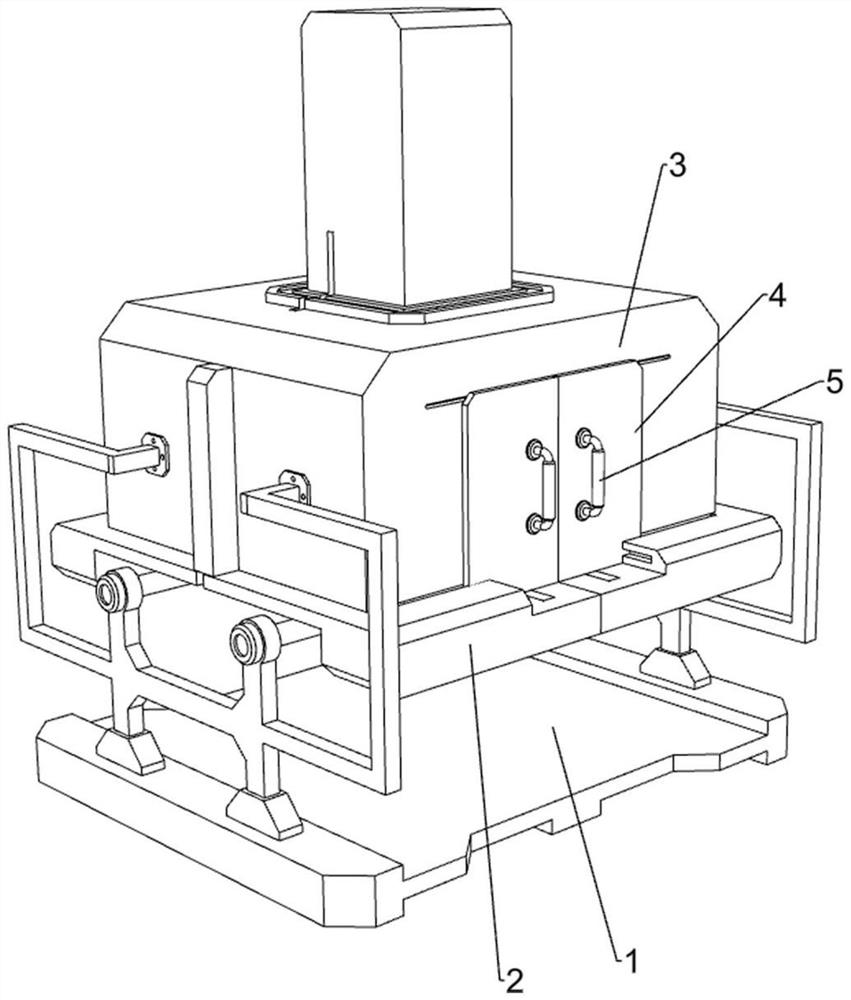

[0038] A compressive test device for building materials, refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 10 , Figure 12 , Figure 13 and Figure 14 , including a support frame 1, a sliding plate 2, a protective frame 3, a baffle 4, a first handle 5, a rotating plate 6, a transparent plate 7, a second handle 8, a first sliding member 9, and a first lifting plate 10 , shock-absorbing spring 11, hydraulic cylinder 12, second lifting plate 13, detection mechanism 14 and clamping mechanism 15, the left and right sides of the middle of the support frame 1 are slidably connected with the sliding plate 2, and the upper and inner sides of the support frame 1 are connected There is a protective frame 3. The protective frame 3 can prevent debris of building materials from splashing around. The front side of the protective frame 3 is slidably connected with two baffles 4. The two baffles 4 are respectively slidingly ...

Embodiment 2

[0043] On the basis of Example 1, refer to figure 1 , figure 2 , Figure 10 and Figure 11, also includes a pulling mechanism 16, the pulling mechanism 16 includes a rack 160, a connecting piece 161, a one-way gear 162, a pulley 163, a pulling rope 164, a first return spring 165, a scroll spring 166 and a rotating shaft 167, the second A rack 160 is symmetrically connected to the rear side of the top of the lift plate 13 , and a connecting piece 161 is symmetrically connected to the top of the protective frame 3 . Both are connected with one-way gears 162. When the rack 160 moves downward, the one-way gears 162 will not rotate. The front sides of the two rotating shafts 167 are connected with pulleys 163, and the two pulleys 163 are both connected with pulleys. 164. The pull rope 164 is used to pull the sliding plate 2 to the outside. The two pull ropes 164 slide through the left and right sides of the protective frame 3 respectively, and the other ends of the two pull rop...

Embodiment 3

[0046] On the basis of Example 2, refer to figure 1 , figure 2 and Figure 12 , also includes a push mechanism 17, the push mechanism 17 includes a motor 170, a screw 171 and a mounting block 172, the inner rear side of the two sliding plates 2 are equipped with a motor 170, and the output shafts of the two motors 170 are connected with the screw 171, Mounting blocks 172 are welded to the outside of the two screws 171 by means of threads. The mounting blocks 172 are used to move the first sliding member 9 back and forth. The two mounting blocks 172 are respectively connected to the two first sliding members 9 by welding.

[0047] When the building materials need to be placed, the two motors 170 can be activated. The output shafts of the two motors 170 drive the two screws 171 to rotate, and the two screws 171 drive the two mounting blocks 172 and the first sliding member 9 to move forward. , when the two first sliders 9 move to the front side to the proper position, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com