Multi-axis sheet feeding system for semiconductor equipment

A semiconductor and equipment technology, applied in the field of multi-axis wafer feeding system for semiconductor equipment, can solve problems such as the inability to meet high-quality or special semiconductor material preparation conditions, meet special process movement requirements, improve compactness, and realize temperature dynamic testing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

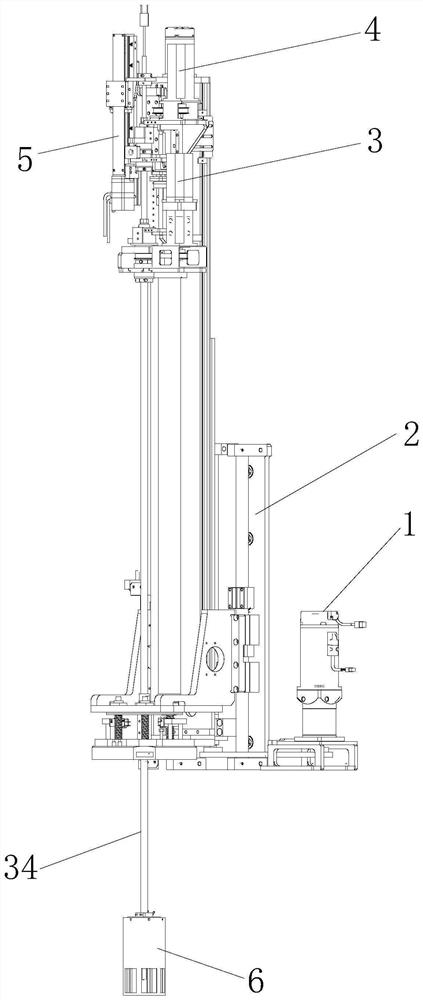

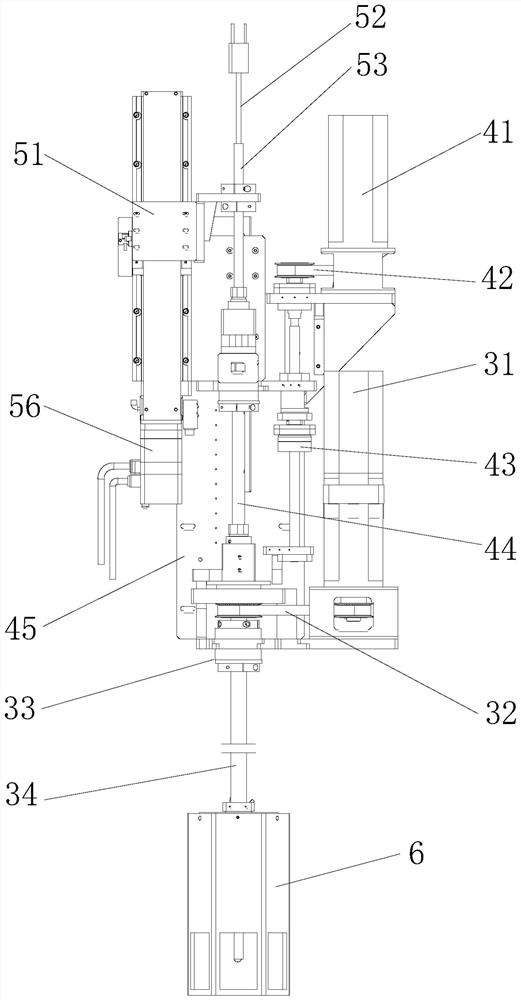

[0033] like Figure 1 to Figure 9As shown, the multi-axis wafer feeding system for semiconductor equipment of the present invention includes: a first driving assembly 1, a first lifting assembly 2, an outer boat assembly 3, an inner boat assembly 4, a thermocouple assembly 5 and a Boat frame assembly 6. The outer boat assembly 3, the inner boat assembly 4, the thermocouple assembly 5 and the boat frame assembly 6 form a multi-axis film feeding unit, and the multi-axis film feeding unit is connected with the first lifting assembly 2, and the output end of the first driving assembly 1 is connected with the first lifting assembly 2. A lift assembly 2 is connected, and the multi-axis wafer feeding unit cooperates with the first drive assembly 1 and the first lift assembly 2 to realize the transfer of the substrate to the semiconductor equipment and complete the corresponding coating process.

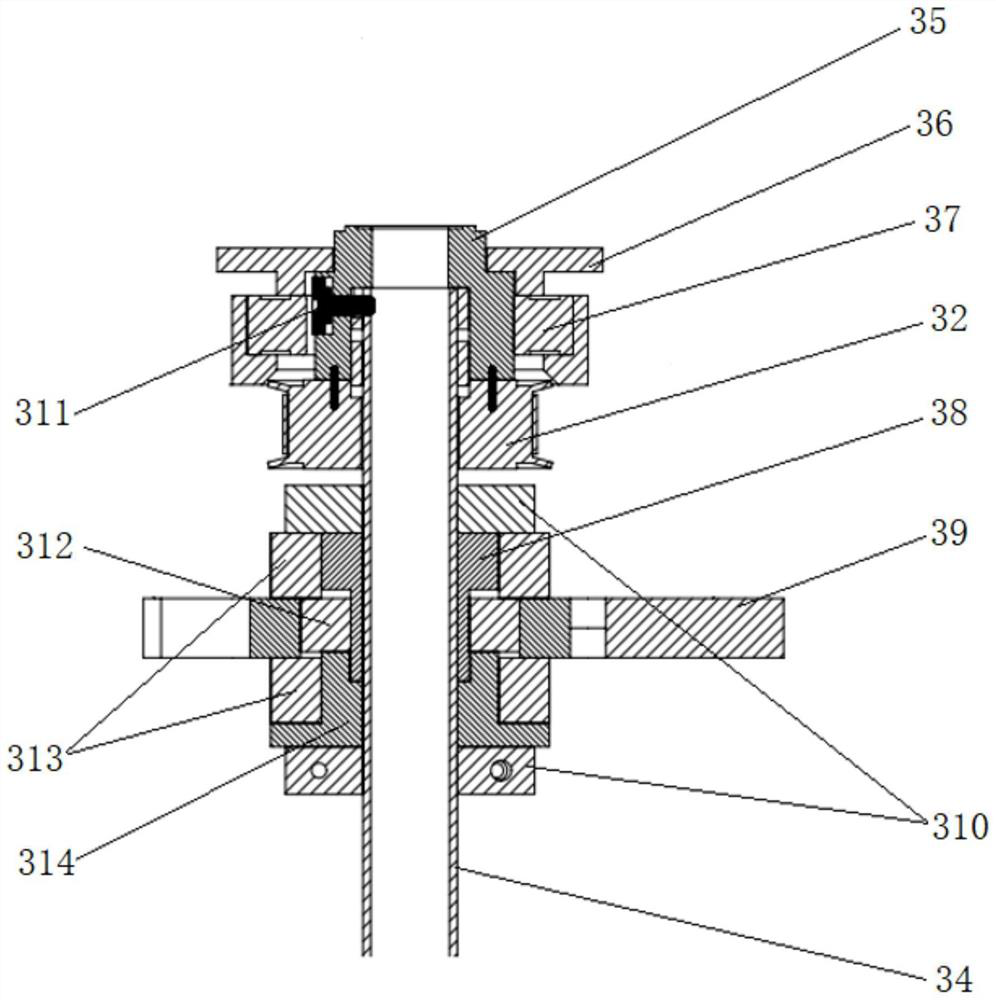

[0034] The outer boat assembly 3 includes a second drive assembly 31 and an outer boat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com