Automatic screening device for high-performance geopolymer cement-based composite material

A geopolymer and composite material technology, applied in cement production, sieving, solid separation, etc., can solve problems such as low efficiency, inability to remove large-particle impurities and small-particle impurities, and achieve convenient operation, simple structure and high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

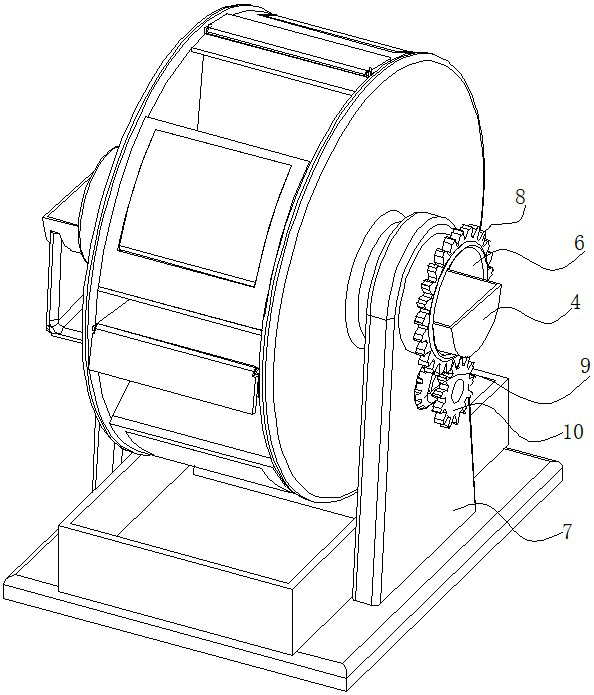

[0038] When the material screening is completed, the box body 17 is removed at this time, and then the motor 9 rotates in the reverse direction. At this time, the large-diameter impurities will move from the second baffle 18 to the first baffle 15, and then move to the filter plate. 13 , and roll down to the partition 14 along the outer side of the filter cartridge 2 , and finally fall from the outer end of the partition 14 .

no. 2 example

[0040] like Image 6 As shown, a window 19 is opened on the side of the first baffle 15, the window 19 is connected to the movable plate 20 by rotation, and a steering gear is installed at the rotating place, and the steering gear drives the movable plate 20 to rotate, so that the movable plate 20 can close and open the window 19. When When it is necessary to discharge large-diameter impurities, remove the box 17, and then the steering gear drives the movable plate 20 to open the window 19. At this time, the motor 9 continues to rotate, so that the impurities can pass through the window when moving on the first baffle 15. 19 discharge.

[0041] In order to prevent the material from moving out from the second baffle plate 18 to the partition plate 14 , the outer end of the partition plate 14 is fixedly installed with an arc-shaped plate 21 .

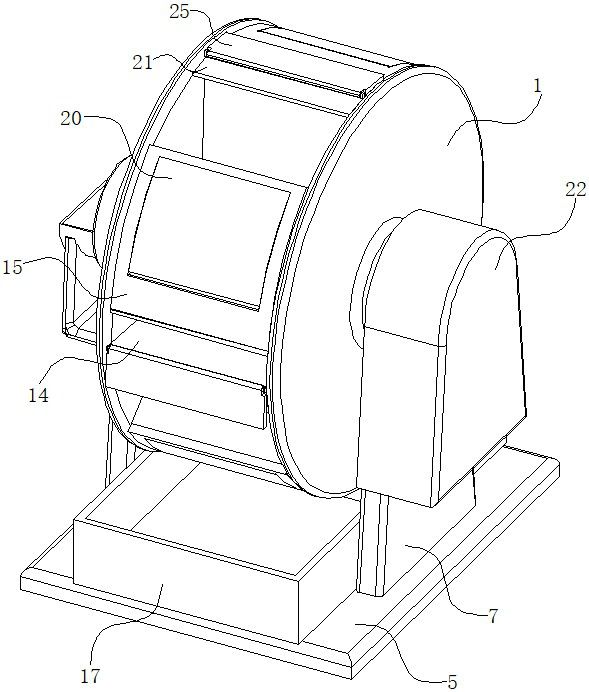

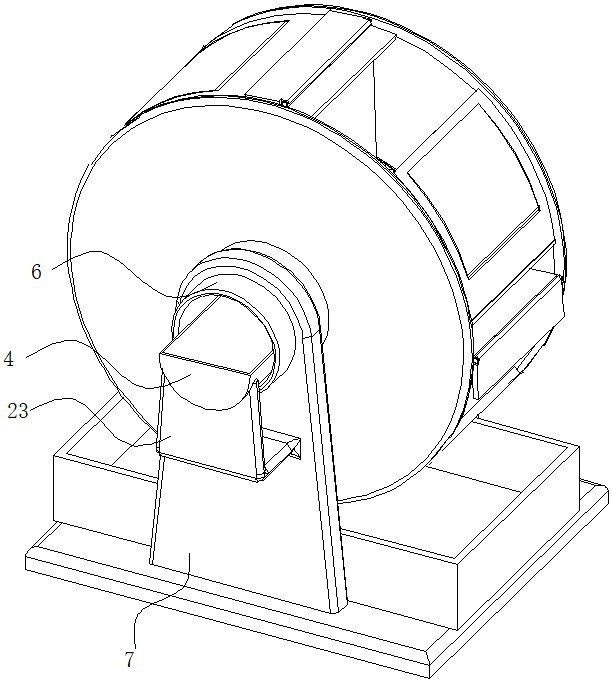

[0042] like figure 1 and Figure 4 As shown, a protective cover 22 is fixedly installed at the position of the shaft seat 7 correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com