Multi-model bit leg journal texture machining clamp

A multi-model, tooth palm technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the processing of tooth palm texture cannot be batched, there is no special fixture for laser ablation processing of tooth palm journal, Troublesome assembly methods and other issues, to avoid repeated disassembly, fast assembly and pick-and-place, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the various embodiments shown in the accompanying drawings, but it should be noted that these embodiments do not limit the present invention. Equivalent transformations or substitutions all fall within the protection scope of the present invention.

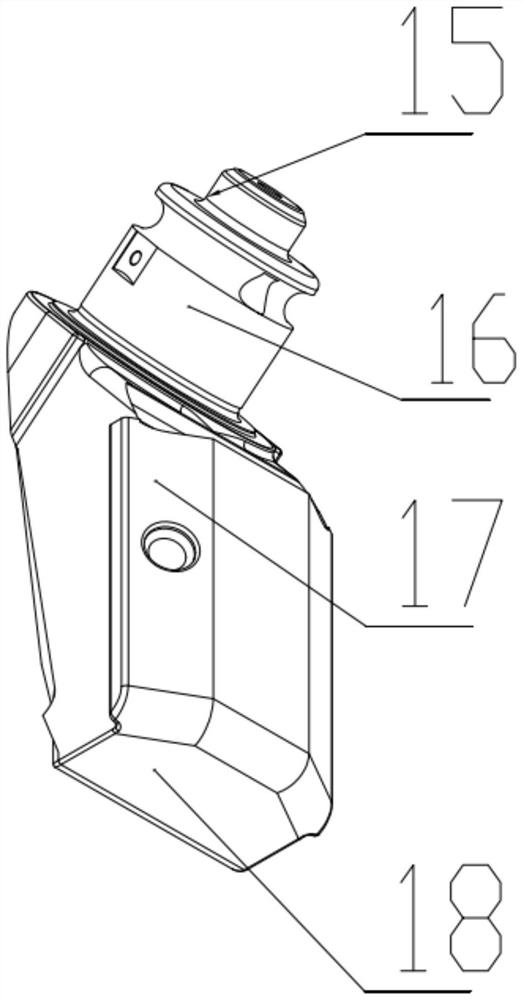

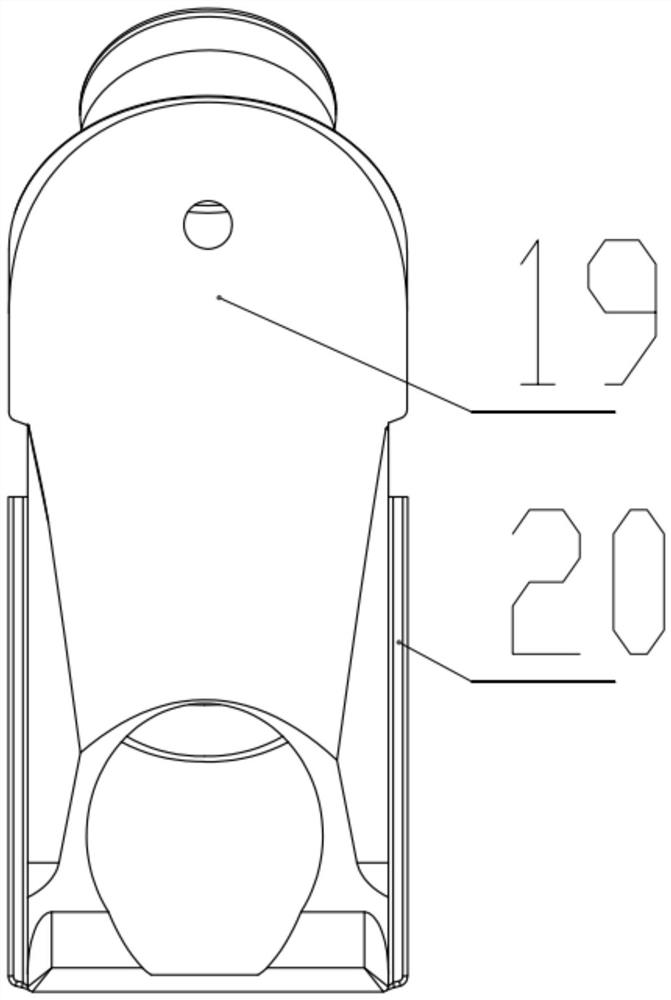

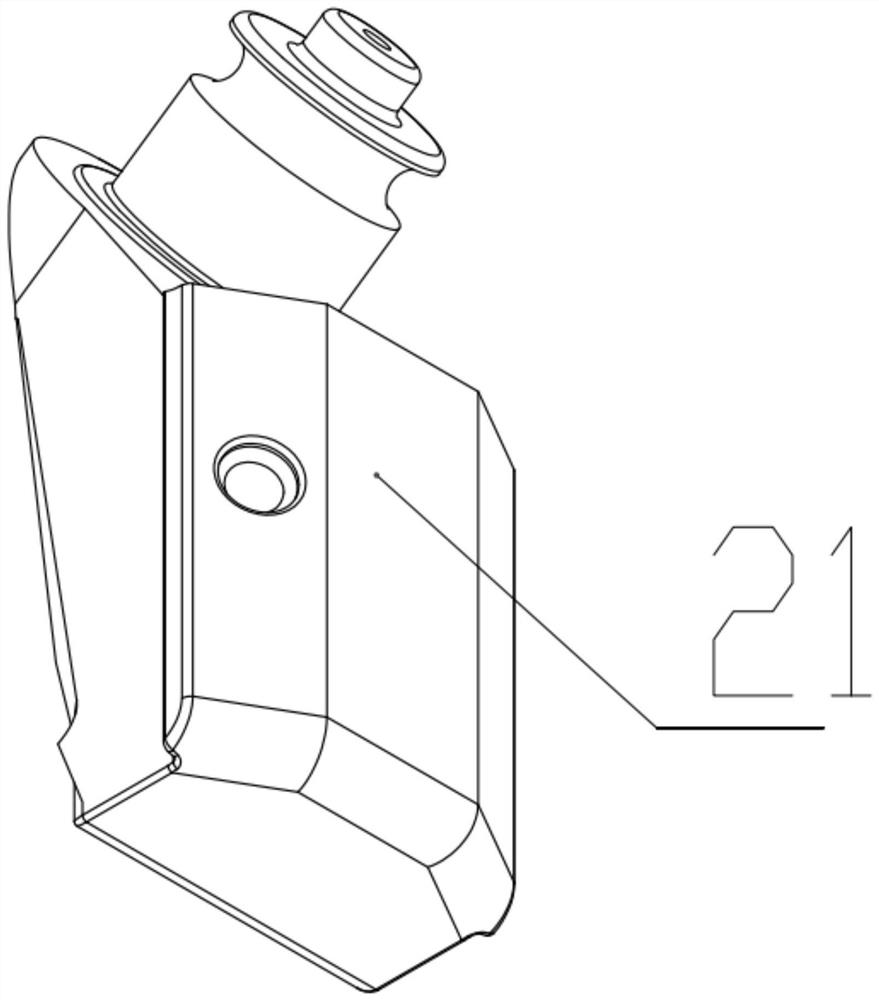

[0022] The patent of the present invention consists of two parts, one is a multi-model tooth palm journal texture processing fixture, the support plate 2 has positioning holes for positioning the counterweight 1, and the support plate 2 has grooves for rotation The positioning and installation of the handle 3, the side of the support plate 2 has an open slot installation chute for the fine-tuning sliding of the fine-tuning block 6, the left and right side plates 4 are provided with an arc-shaped chute to adapt to different types of tooth palms , the fixed auxiliary plate 9 is respectively installed on the left and right side plates, the left fixed aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com